Automobile maintenance accessory cabinet

A technology for car maintenance and accessories cabinets, applied in tool storage devices, manufacturing tools, etc., can solve the problems of single use and poor practicability, and achieve the effects of reducing occupancy, improving practicability, and facilitating classification and access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

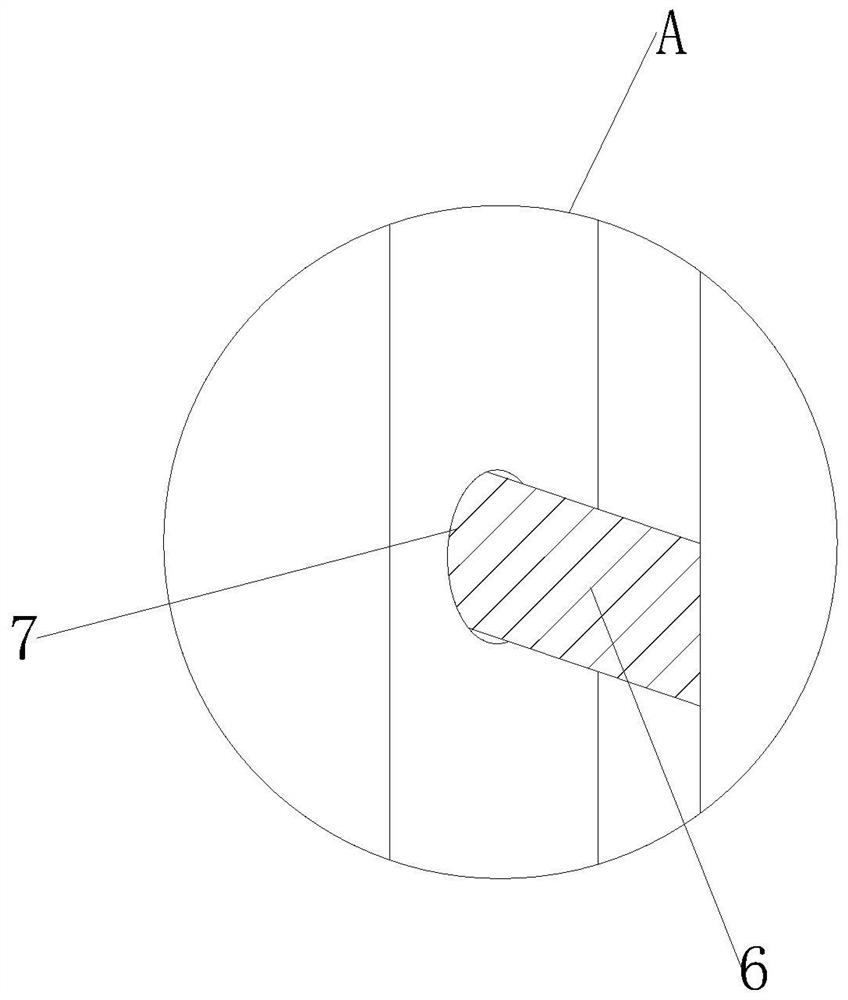

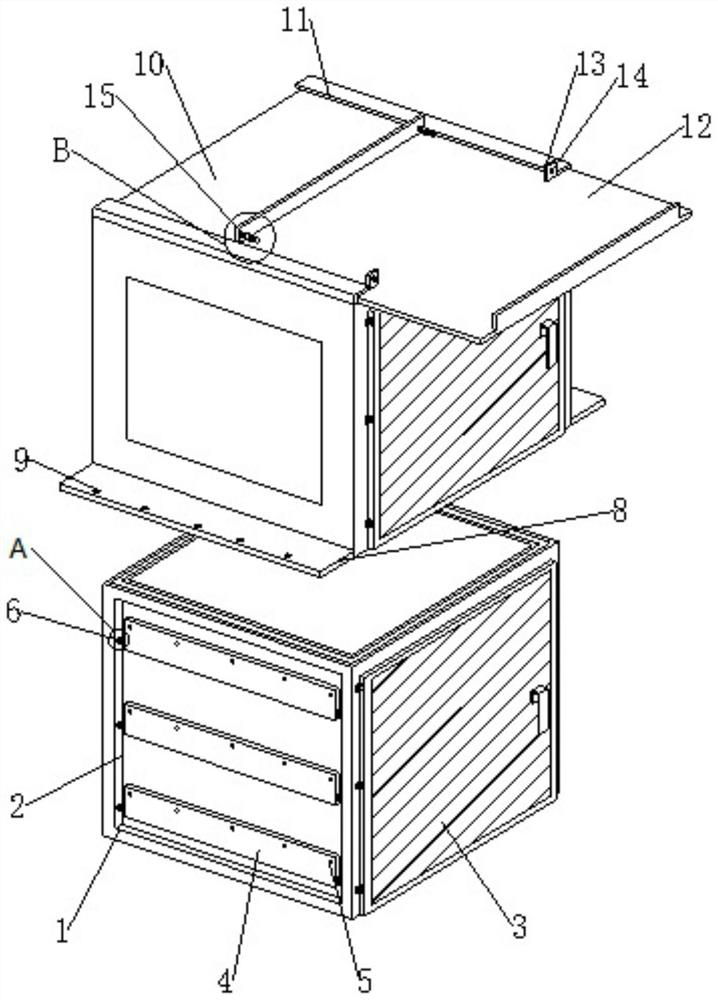

[0022] Embodiment 1, an automobile repair parts cabinet includes: a main cabinet 1, the main cabinet 1 includes an auxiliary cabinet 10 arranged directly above it, the bottom of the auxiliary cabinet 10 is open, and the bottom of the auxiliary cabinet 10 is open Matching with the main cabinet 1, there are side notches 2 on the left and right sides of the main cabinet 1, and three groups of uniformly arranged turning holes 7 are opened on the front and rear sides of the inner wall of the side notch 2, and the side notches 2 There are three long boards 4 corresponding to the positions of the rotating holes 7 arranged vertically inside. The outer wall of the long board 4 is provided with a mounting hole 5 penetrating to the inner wall thereof, and the front and rear sides of the long board 4 are welded with the The rotating shaft 6 screwed to the rotating hole 7, the long plate 4 is connected to the rotating hole 7 through the rotating shaft 6, the left and right sides of the bott...

Embodiment 2

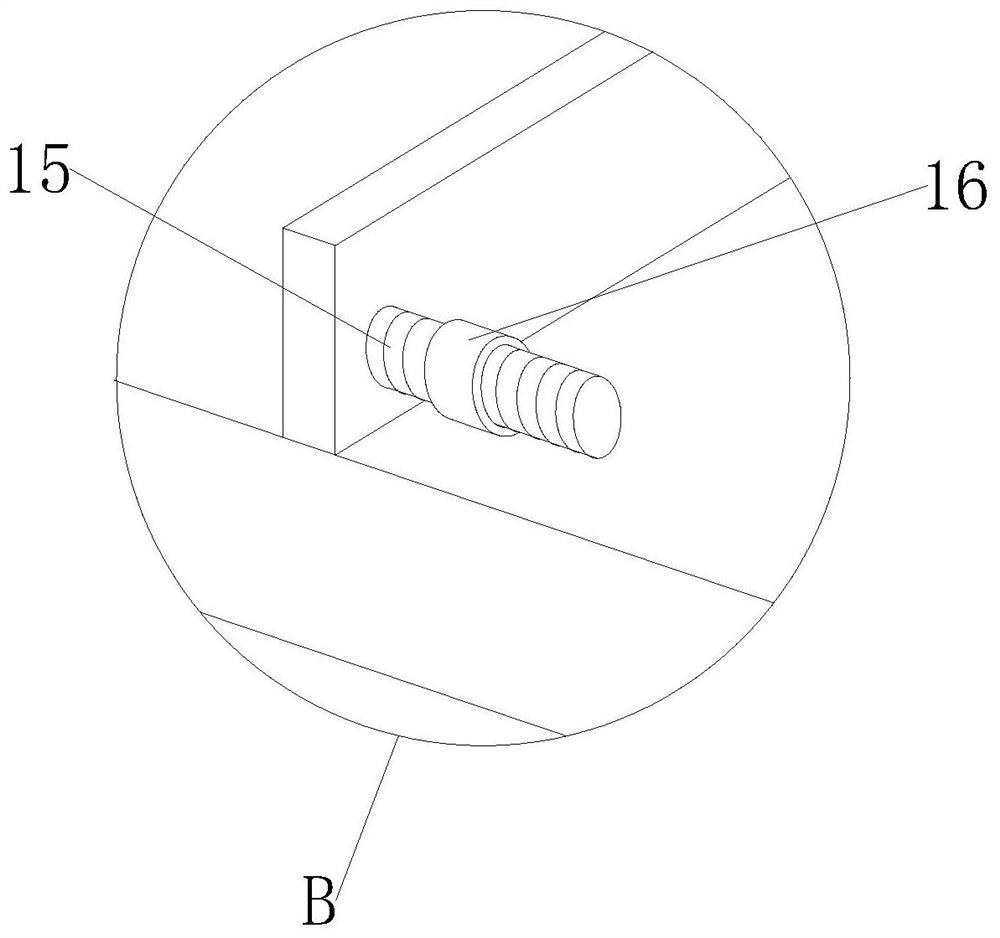

[0023] Example 2, such as figure 1 as well as image 3 As shown, two symmetrical upper platens 11 are welded on the left and right sides of the top of the auxiliary cabinet 10, and the inner side of the front end of the upper platen 11 is fixed with a block 13, and the front end of the block 13 is provided with a hole that runs through to the rear end. A circular hole 14, and a push plate 12 is movably connected between the upper pressing plate 11 and the auxiliary cabinet 10, and two straight shafts 15 are welded on the left and right sides of the rear end of the push plate 12, and the position of the straight shaft 15 is in line with the circle The hole 14 corresponds, and the diameter of the straight shaft 15 is equal to that of the circular hole 14, and a nut 16 is screwed on the straight shaft 15, and at the same time, the user can pull the push plate 12 forward during maintenance. , until the rear end of the push plate 12 is gradually approaching the block 13, then unsc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com