Foldable disassembly-assembly plastic circulation box

A plastic turnover box and shaft technology, applied in packaging, transportation and packaging, containers to prevent decay, etc., can solve the problems of no moisture-proof effect, fresh-keeping and dust-proof effect, inability to change storage space, inflexible disassembly and installation, etc. Durability, increased storage space, flexible disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

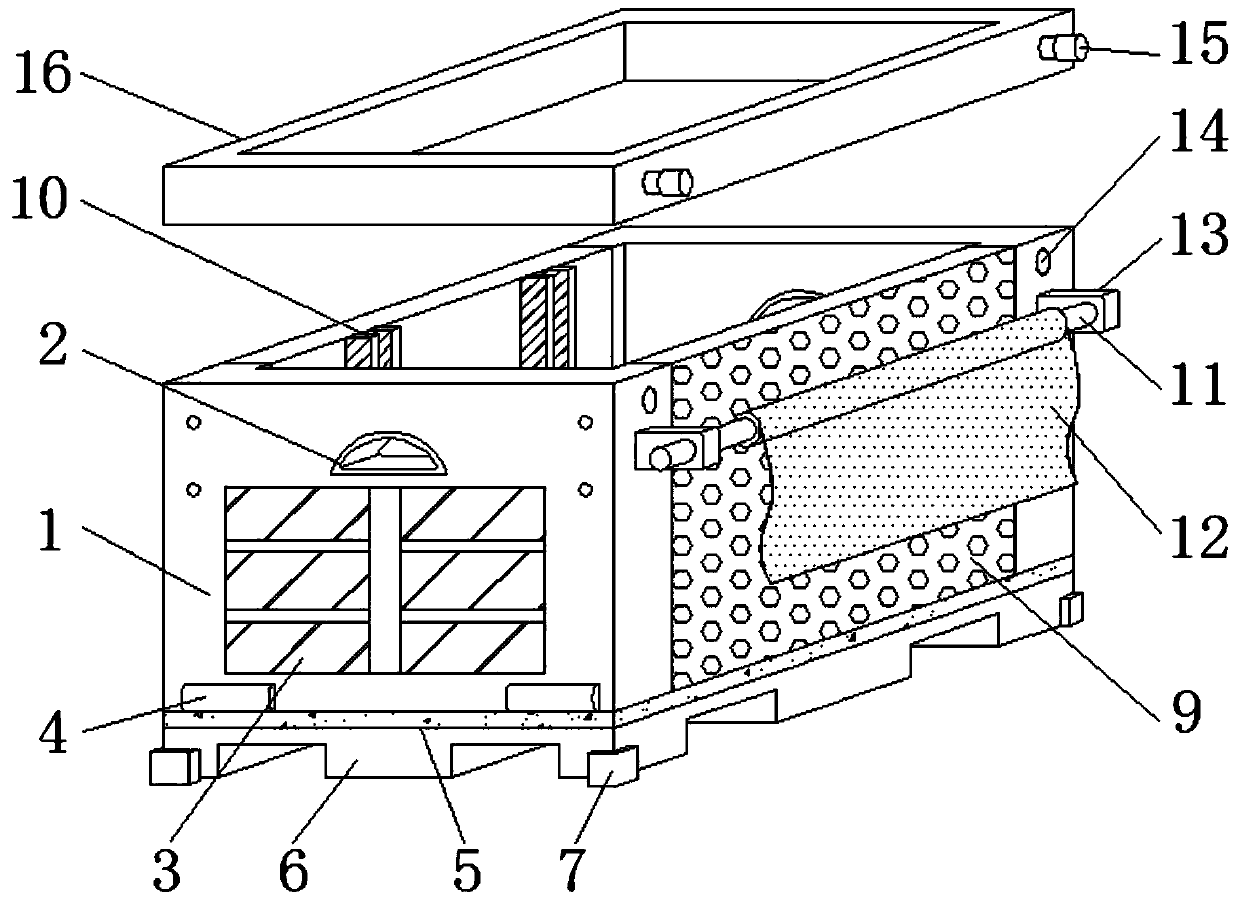

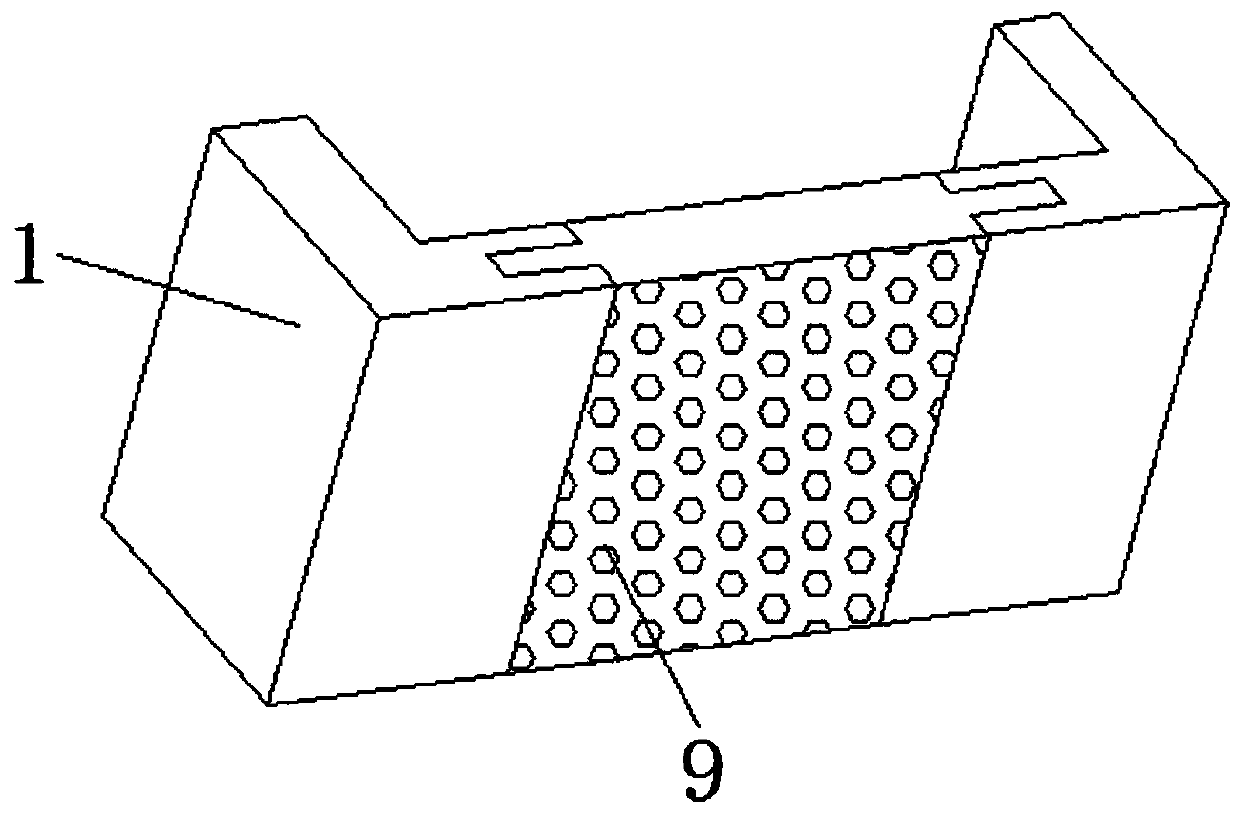

[0021] Example 1, such as figure 1 The middle mounting plate 3 is a detachable structure inside the first baffle 1, and the first baffle 1 is a rotating structure on the moisture-proof layer 5 through the rotating shaft 4. The first baffle 1 can be rotated and unfolded, and the operation is very simple and convenient, as figure 1 The middle sleeve frame 16 is snapped on the upper ends of the first baffle plate 1 and the second baffle plate 9, and the first baffle plate 1 and the second baffle plate 9 are threadedly connected with the sleeve frame 16 through the fixing nut 15, and the sleeve The frame 16 is a frame structure, through which the first baffle 1 and the second baffle 9 can be connected and fixed, making the device more stable and not easy to disperse.

Embodiment 2

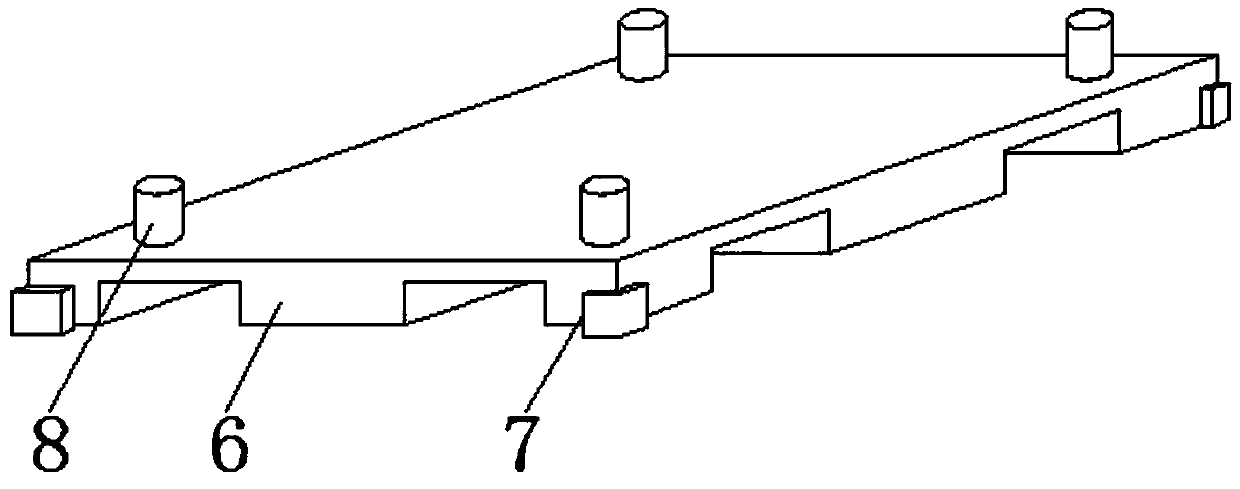

[0022] Example 2, such as figure 1 There are 4 sets of middle buffer pads 7 with respect to the center of the base 6, and the connection mode between the base 6 and the moisture-proof layer 5 is adhesive connection, the lower surface of the base 6 has a "Tian"-shaped structure, and the base 6 is connected to the second through the bump 8. The connection mode of a baffle plate 1 is a card slot connection, and the function of the moisture-proof layer 5 makes the device have a moisture-proof effect, preventing moisture from infiltrating into the interior and damaging the product quality, such as figure 1 The central axis rod 11 is a rotating structure inside the fixed block 13, and the fixed block 13 is welded on the right surface of the first baffle plate 1, so that the rotation of the shaft rod 11 facilitates the film 12 to be pulled out to close the top of the device. On the one hand, it has the function of dust prevention, on the other hand, it can keep some fruits and vegeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com