Airflow impact type nonferrous metal smelting device

A technology for non-ferrous metals and smelting devices, which is applied in the direction of stirring devices, crucible furnaces, furnaces, etc., which can solve the problems of limited working space and low melting efficiency of non-ferrous metals, and achieve the effects of increasing the degree of heating, improving the effect of heating, and strengthening the degree of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

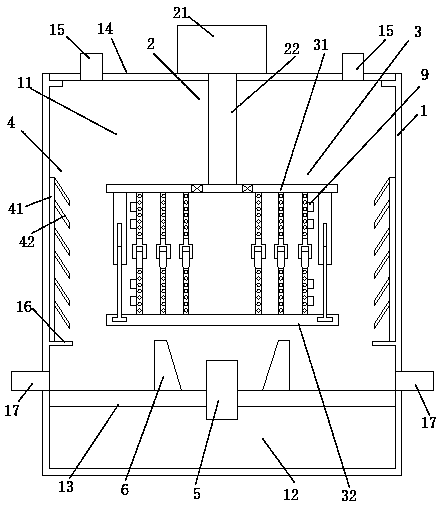

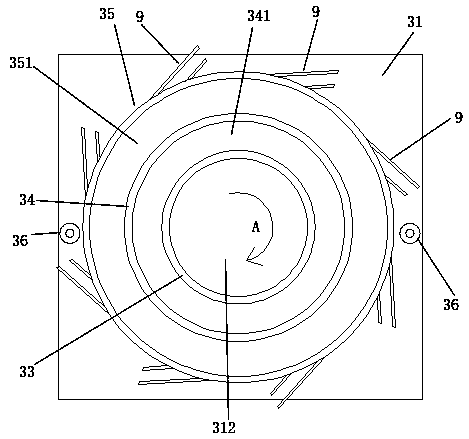

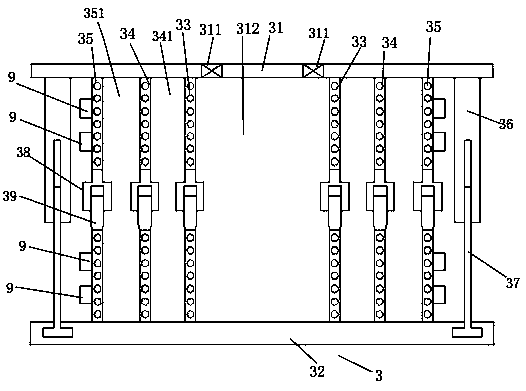

[0021] like Figures 1 to 3 As shown, an airflow impingement non-ferrous metal smelting device includes a furnace body 1, a rotary drive mechanism 2, a smelting mechanism 3, and a gas flow pipe body 9. The inside of the furnace body 1 is provided with a smelting chamber 11; the rotary drive mechanism 2 is installed on the upper end of the furnace body 1; the smelting mechanism 3 is installed in the middle of the furnace body 1; the rotary drive mechanism 2 drives the smelting mechanism 3 to rotate Movement; the smelting mechanism 3 includes an upper connecting plate 31, a lower connecting plate 32, an inner annular mesh body 33, an intermediate annular mesh body 34, an outer annular mesh body 35, a socket ring 38, a floating ring 39, and an adjustment internal thread Column 36, adjusting screw rod 37. The upper connecting plate 31 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com