Polytetrafluoroethylene butterfly valve preprocessing device capable of saving raw materials

A polytetrafluoroethylene and preprocessing technology, applied in the field of polytetrafluoroethylene butterfly valve preprocessing devices, can solve the problems of raw material waste, agglomeration, uneven product density, etc., and achieve the effect of ensuring product quality and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

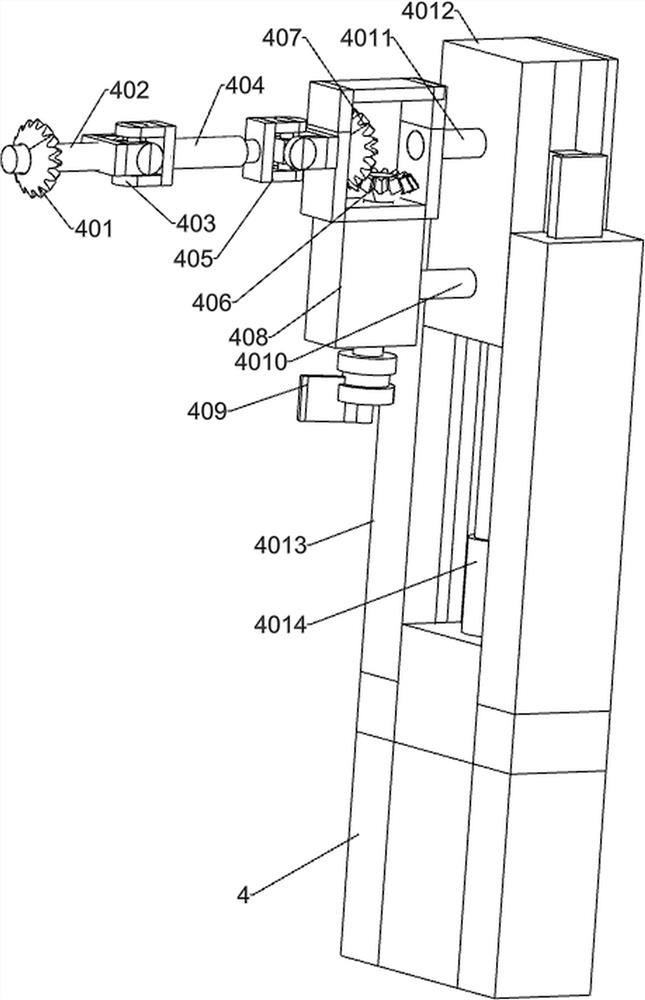

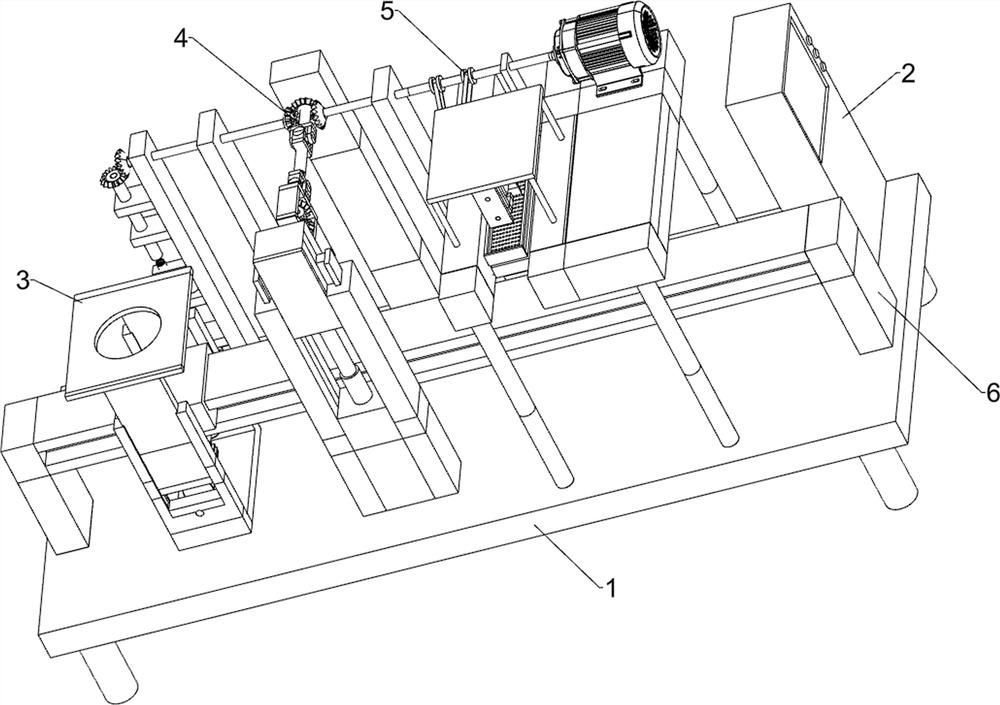

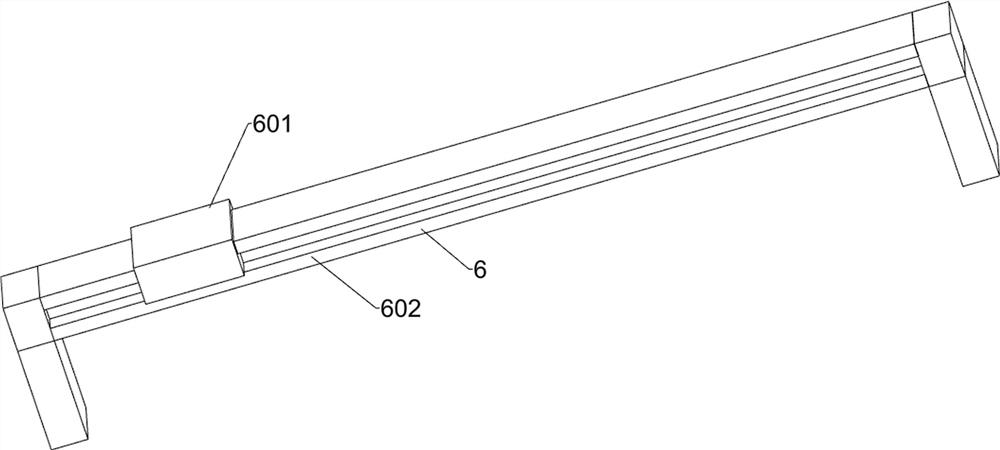

[0025] A PTFE butterfly valve preprocessing device that can save raw materials, such as Figure 1-6 As shown, it includes workbench 1, control panel 2, receiving assembly 3, leveling assembly 4, vibration assembly 5 and transport assembly 6; workbench 1 is connected with control panel 2; workbench 1 is connected with accepting assembly 3; working Table 1 is connected with leveling assembly 4; workbench 1 is connected with vibration assembly 5; workbench 1 is connected with transport assembly 6; receiving assembly 3 is connected with leveling assembly 4; leveling assembly 4 is connected with vibration assembly 5.

[0026] When the device is in use, first open and adjust the device through the control panel 2 on the workbench 1, and then manually place the lower mold of the butterfly valve on the transportation component 6, and put the polytetrafluoroethylene powder on the vibration component 5, and pass through the vibration component 5 Completely pulverize the polytetrafluoroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com