Plate pushing power system

A power system and plate technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of reasonable structure and good pushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

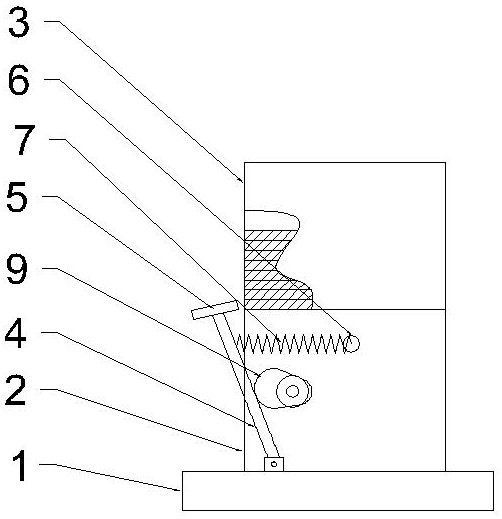

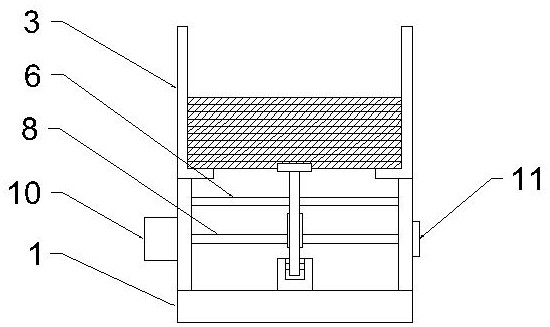

[0009]The present invention will be further described below in connection with all of the drawings, and preferred embodiments of the present invention are: see attachedfigure 1 Attachfigure 2The sheet push power system according to the present embodiment includes a rack 1, and the rack 1 is vertically fixed, and a plate plate 2 is attached to the top of the distribution side plate 2, two A plate placing zone is formed between the plate placement 3, and the top of the frame 1 between the two part plates 2 is hinged by the hinged shaft activity, and the push plate 5 is attached to the top of the swing arm 4, and the push plate 5 is located. On one end of the plate placement area, the two plates placed frames 3 of the other end of the plate placement area are opposite to the bending forming plate, and the two pieces of substrate side panel 2 are fixed to the opposite side of the plate, and the two pallets are formed between the two pallets. The arm 4 reserves the retention of the resol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com