Control valve

A technology for controlling valves and valve seats, applied to valve details, valve devices, valve housing structures, etc., can solve problems such as high energy consumption, heating methods that cannot be applied to new energy vehicles, and impact on the mileage of new energy vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be described below with reference to the drawings.

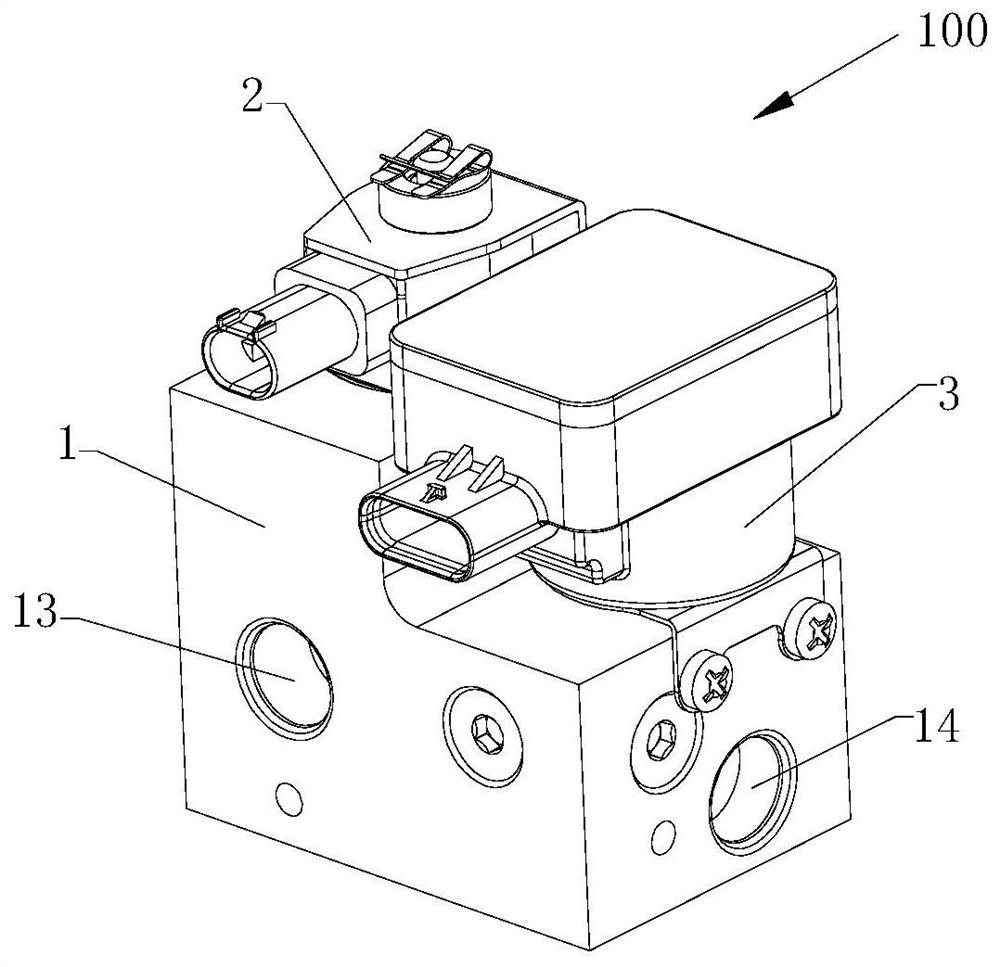

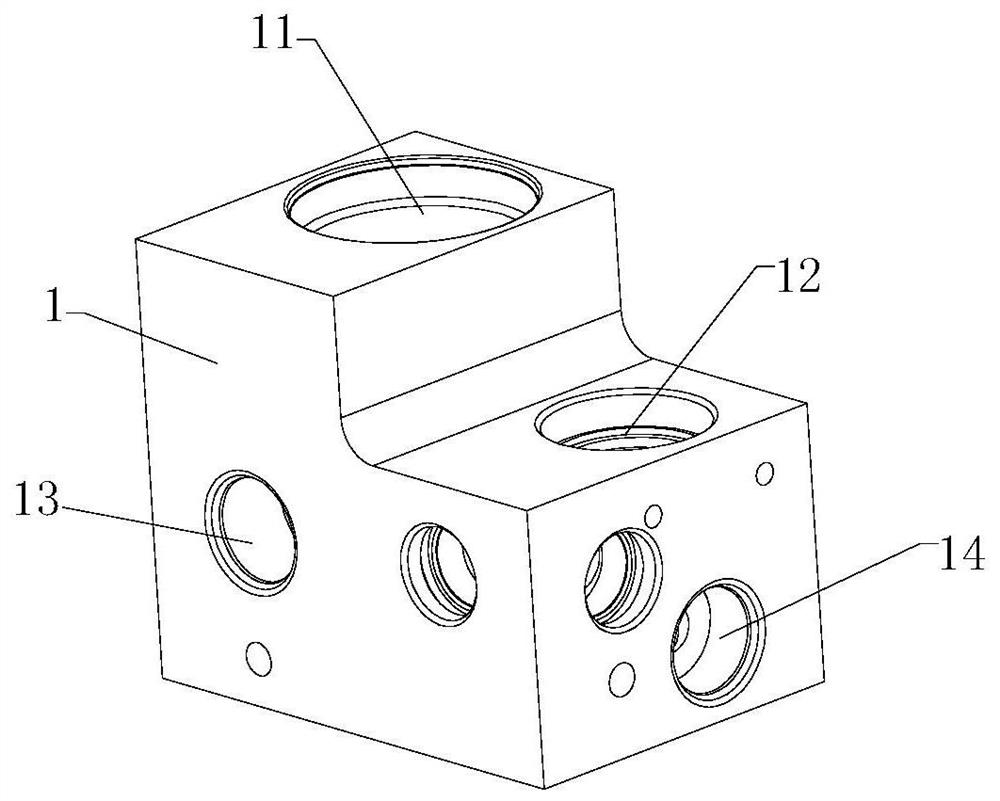

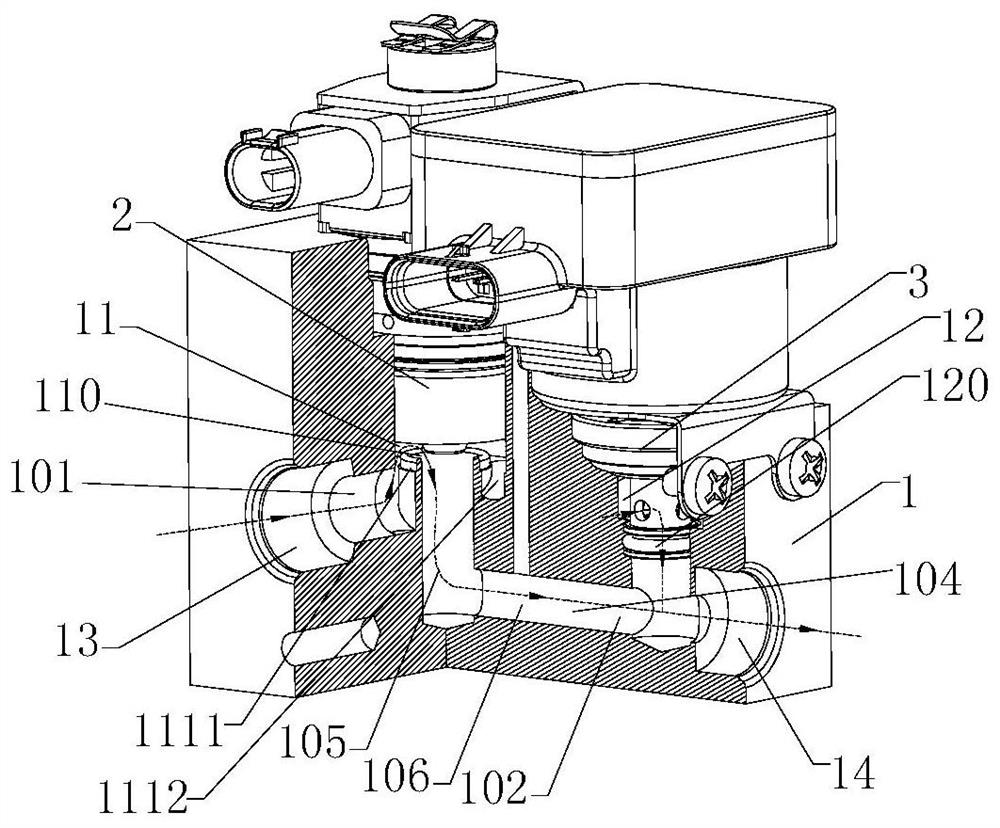

[0022] Please refer to Figure 1 to 6 As shown, a control valve 100 includes a valve seat 1 and a solenoid spool member 2, a valve seat 1 including a first valve chamber 11, and the solenoid spool member 2 is at least partially located at the first valve chamber 11, the solenoid spool member 2. The portion is fixed to the valve seat 1, and the solenoid spool member is fixed by a threaded connection. The valve seat 1 also includes a first interface passage 101 and a second interface passage 102, and the first interface passage 101 communicates with the first valve chamber 11, and the control valve 100 can control the first interface passage 101 and the second interface passage 102.

[0023] The control valve 100 also includes a throttle core member 3, and the valve seat 1 further includes a second valve chamber 12, and the throttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com