Primary separation tower for carbon disulphide preparation process

A carbon disulfide and preliminary separation technology, applied in the field of preliminary separation towers, can solve the problems of difficult maintenance and repair, many leakage points, large space occupation, etc., and achieve the effect of reducing equipment maintenance costs, reducing the number of equipment, and connecting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

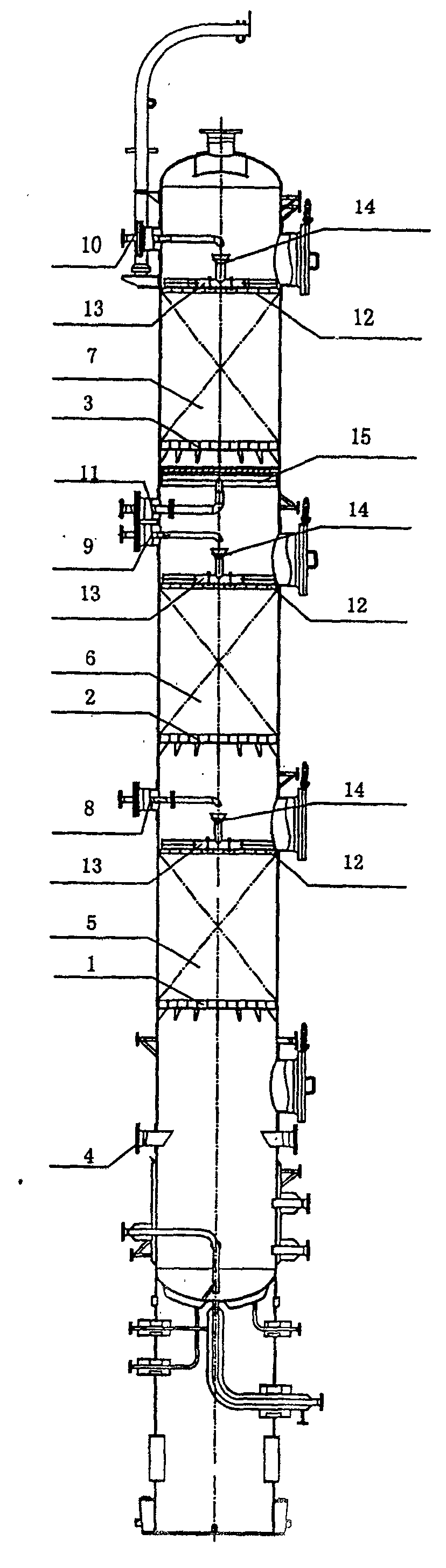

[0013] The preliminary separation tower used in the production process of carbon disulfide includes a tower body, two layers of grid plates 2 and 3 are arranged in the tower body, a packing layer is arranged on each layer of grid plate, and a feed liquid inlet is arranged above each packing layer, and the tower body The lower part is provided with a mixture liquid inlet 4, and a layer of grid plate 1 is provided below the grid plate 2 in the tower body, and a packing layer 5 is arranged on the grid plate 1. At this time, the tower body is called the first packing layer 5 from bottom to top. The second packing layer 6 and the third packing layer 7, wherein a carbon disulfide feed port 8 is provided above the first packing layer 5, a liquid sulfur feed port 9 is provided above the second packing layer 6, and a liquid sulfur feed port 9 is provided above the third packing layer 7. The carbon disulfide feed port 10 is provided with a carbon disulfide discharge port 11 below, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com