Carbon dioxide pipeline flow regulation and differential pressure flowmeter precision test and calibration system

A differential pressure flowmeter, carbon dioxide technology, used in testing/calibration devices, control/regulation systems, flow control, etc., can solve problems such as accuracy error, poor carbon dioxide flow accuracy, and unusable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

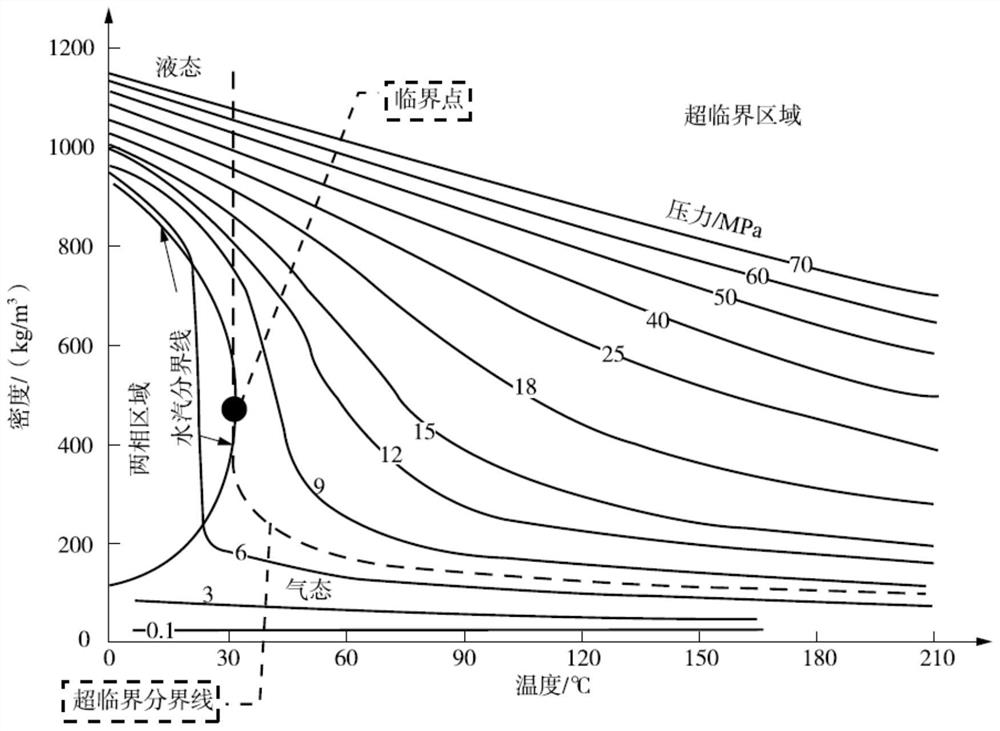

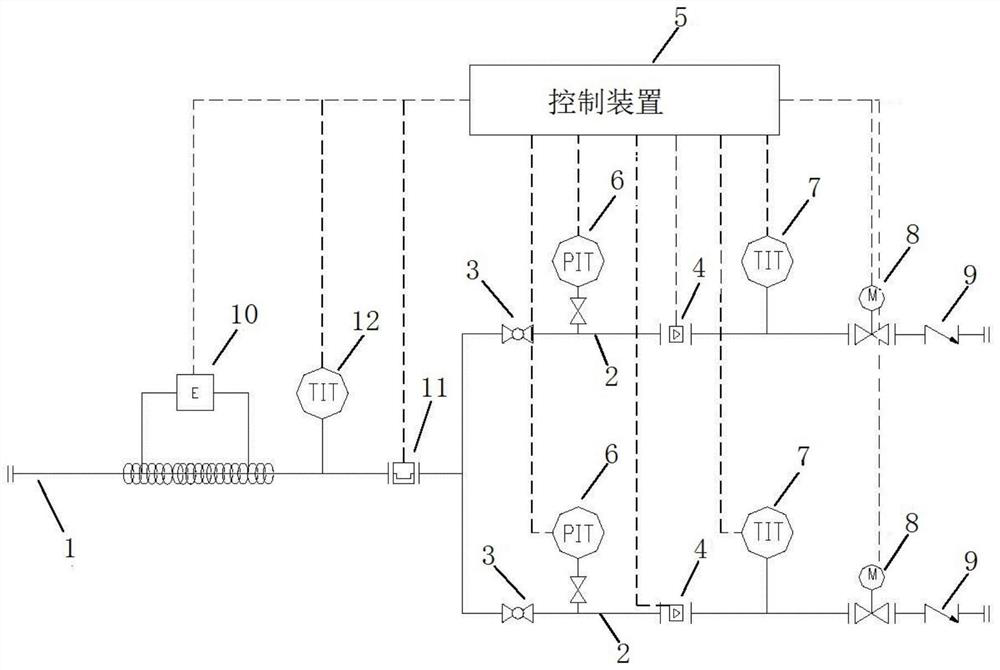

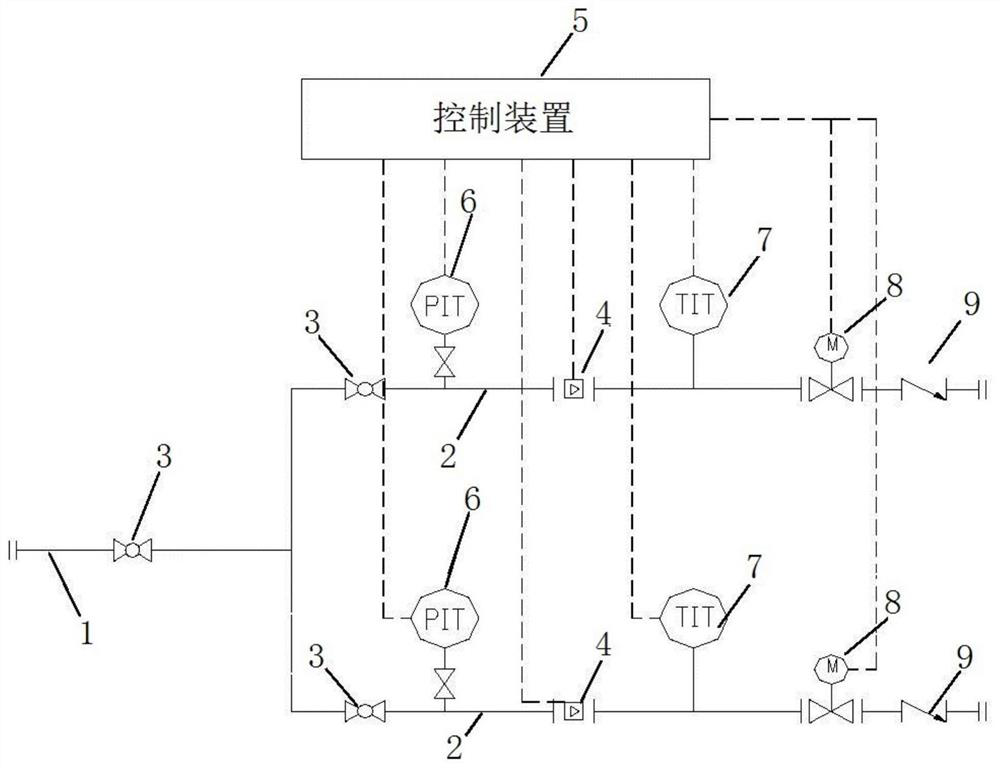

[0045] In order to realize the precise measurement of liquid, dense-phase and supercritical carbon dioxide flows by the differential pressure flowmeter in the carbon dioxide delivery pipeline, and realize the automatic distribution and adjustment of the carbon dioxide flow in each branch of the carbon dioxide delivery pipeline based on this, the present invention provides A system for testing and calibrating the accuracy of a differential pressure flowmeter in a carbon dioxide pipeline, such as figure 2 As shown, it uses the carbon dioxide density compensation method to convert the differential pressure data measured by the differential pressure flowmeter in each branch pipeline into carbon dioxide mass flow rate, and uses the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com