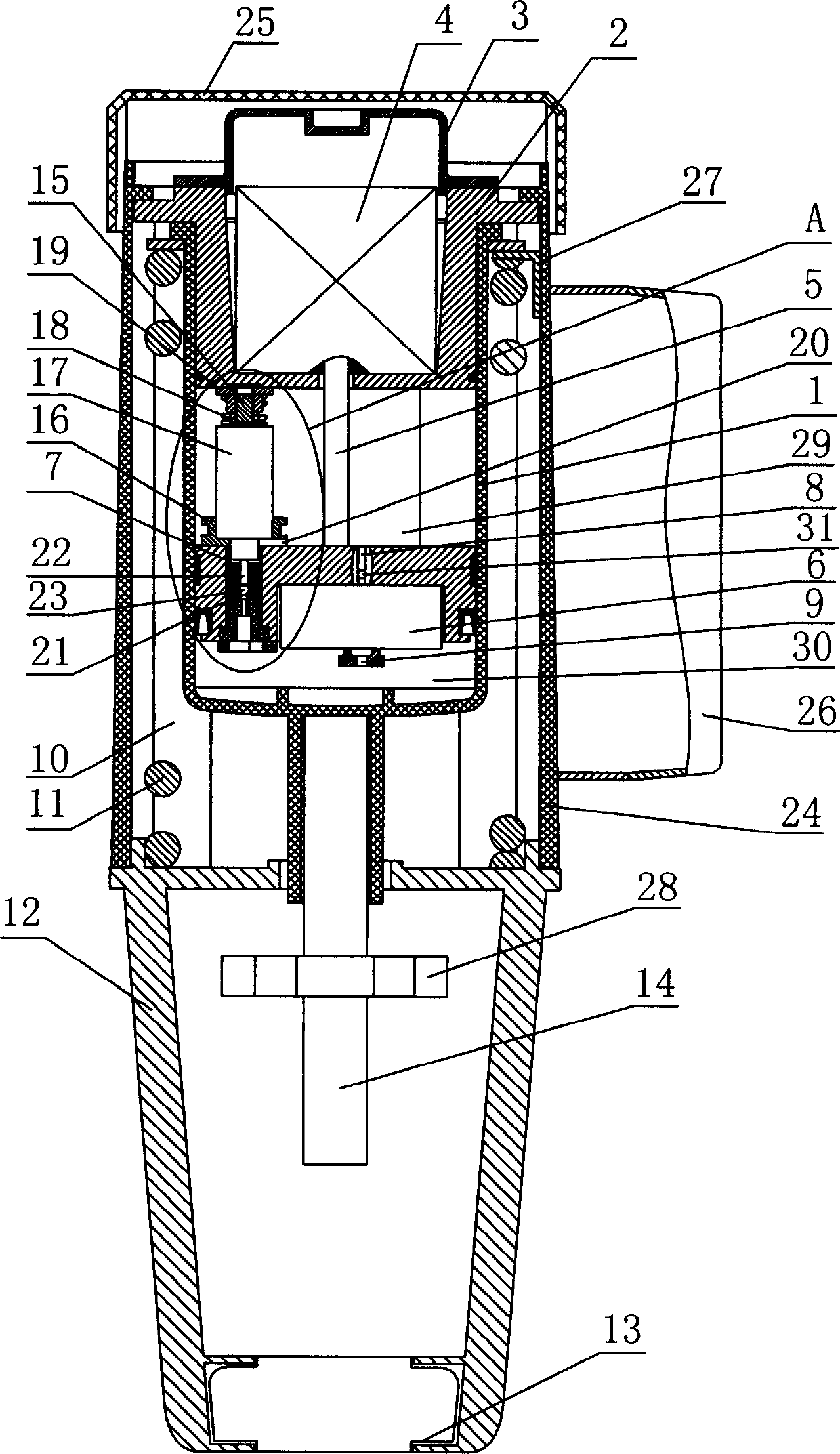

Electric hydraulic executing device

An actuator and hydraulic technology, applied in the direction of valve device, valve operation/release device, engine components, etc., can solve the problems of low control accuracy, cumbersome maintenance work, large device volume, etc., and achieve adjustable valve closing speed, The design is reliable and the effect of reducing work loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

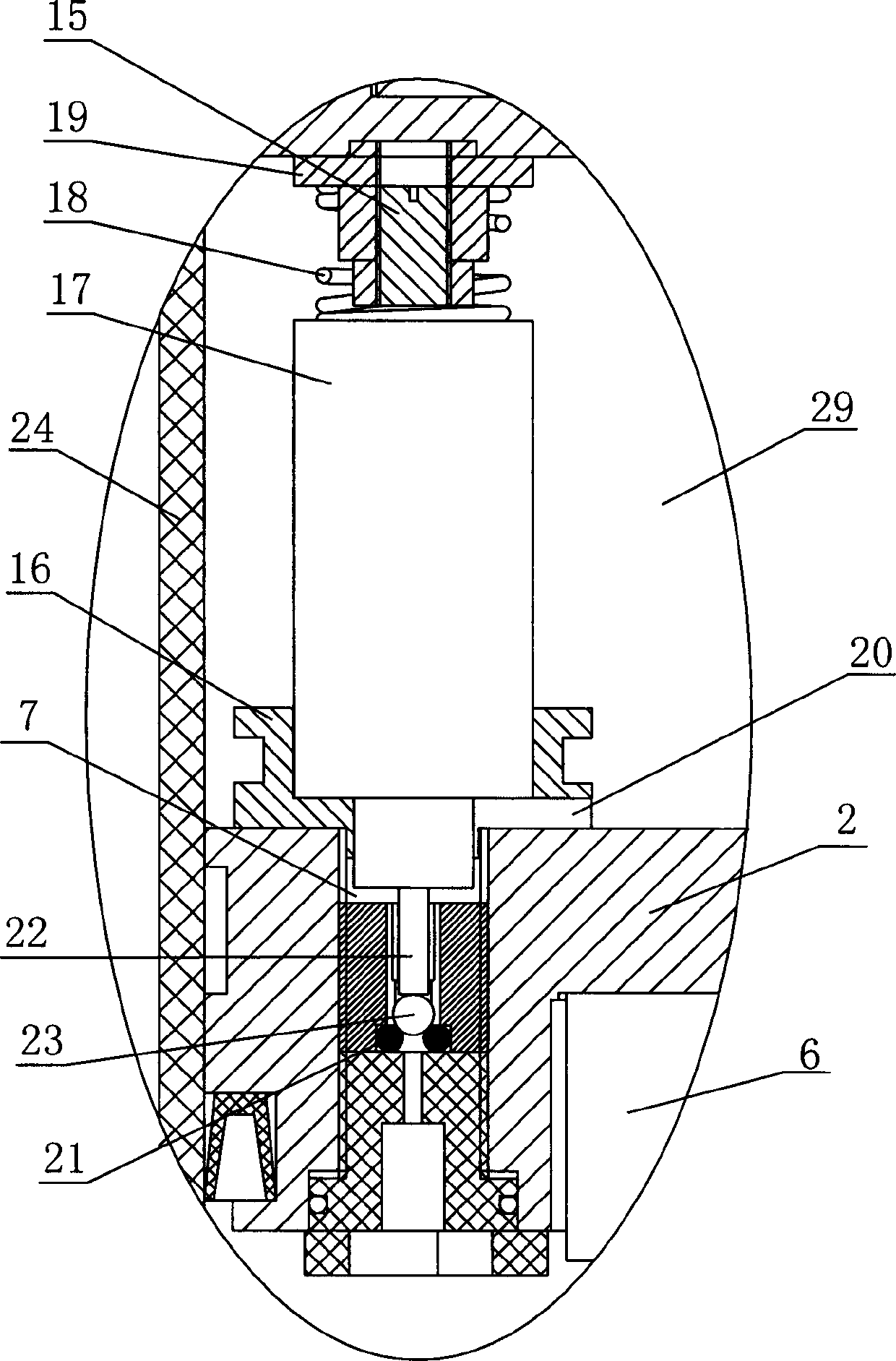

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0024] Such as Figure 1-2 Shown, the present invention comprises support 12, is provided with buckle 13 at support 12 lower ends, is provided with several pull rods 10 evenly along the circumference at support 12 top edge, and the top of pull rod 10 is connected with a piston 2 tops, on the piston 2 A cylinder body 1 is sleeved on the outer side, and the upper end of the return spring 11 sleeved on the outside of the cylinder body 1 is in conflict with the top end of the cylinder body 1 , and the lower end is in conflict with the top end of the support 12 . The piston 2 cooperates with the cylinder body 1 outside the piston 2 to form a normal pressure oil chamber 29 and a high pressure oil chamber 30 which are sealed and isolated from each other under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com