Microminiature laser linear module

A micro-miniature, laser technology, used in lasers, laser parts, semiconductor lasers, etc., can solve problems such as bulky volume and narrowing of linear light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

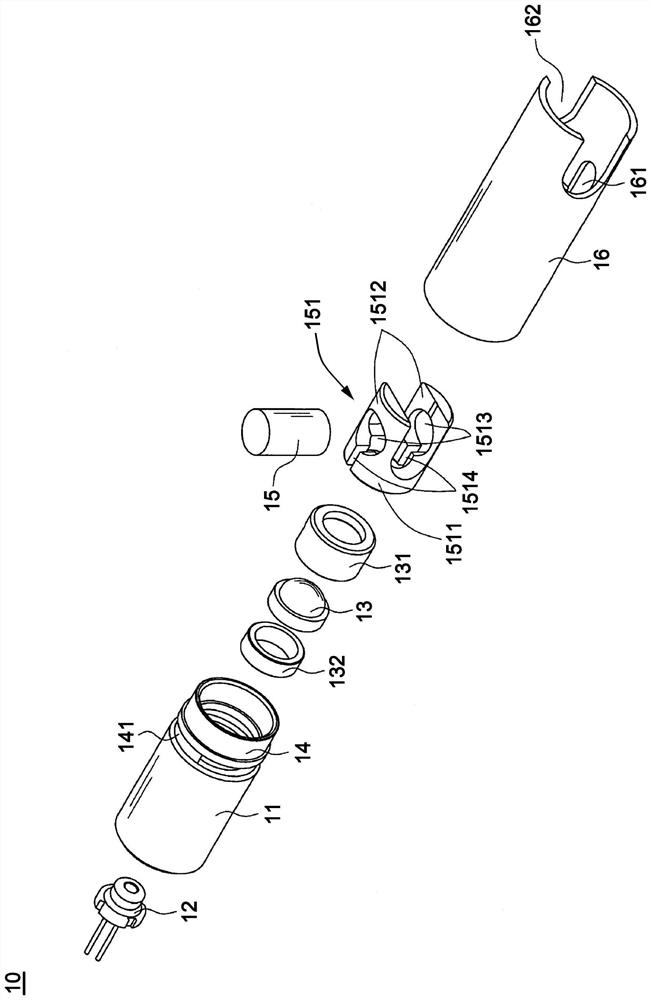

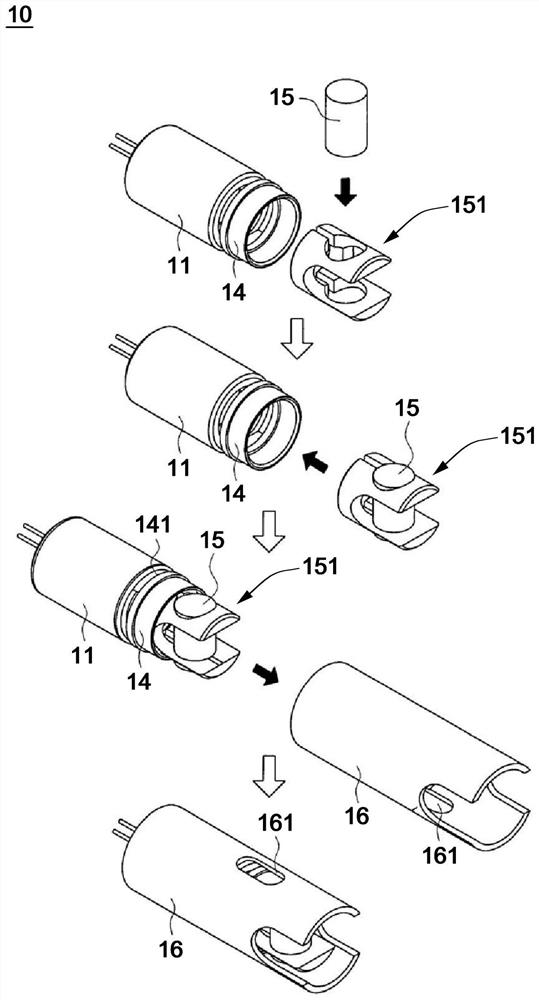

[0026] First, see Figure 2A ~ Figure 6 As shown, a preferred embodiment of a miniature laser line module 20 of the present invention includes: a heat sink 21 with a fixing frame 211 formed above it, and a plurality of pins 212 disposed below it.

[0027] A laser diode chip 22 is installed on the fixing frame 211 .

[0028] A cover 23 seals the cooling seat 21, and the cover 23 is provided with an accommodating groove 231 and a light exit window 232 on it, and the light exit window 232 is located in front of the accommodating groove 231, and the The accommodating groove 231 communicates with the light-emitting window 232 , and the position of the laser diode die 22 corresponds to the position of the accommodating groove 231 and the light-emitting window 232 .

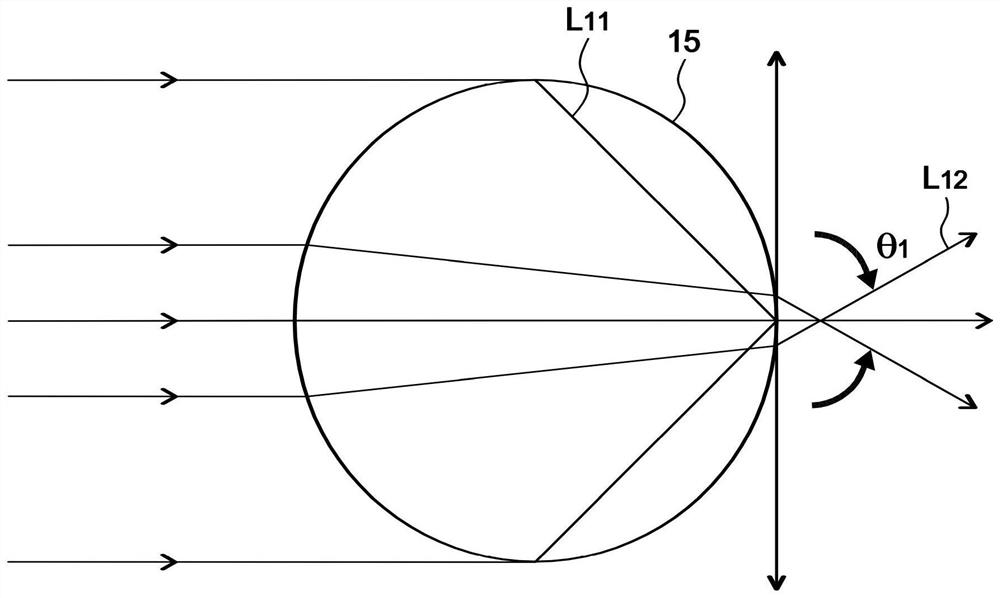

[0029] A lenticular lens 24 is installed in the receiving groove 231, and a first surface 241 and a second surface 242 on the opposite side are set, so that the first surface 241 is separated by a first small distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com