Drawer assembly of dish-washing machine and dish-washing machine

A dishwasher and drawer technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household cleaning devices, etc. Problems such as positioning and installation of side panels and bottom brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

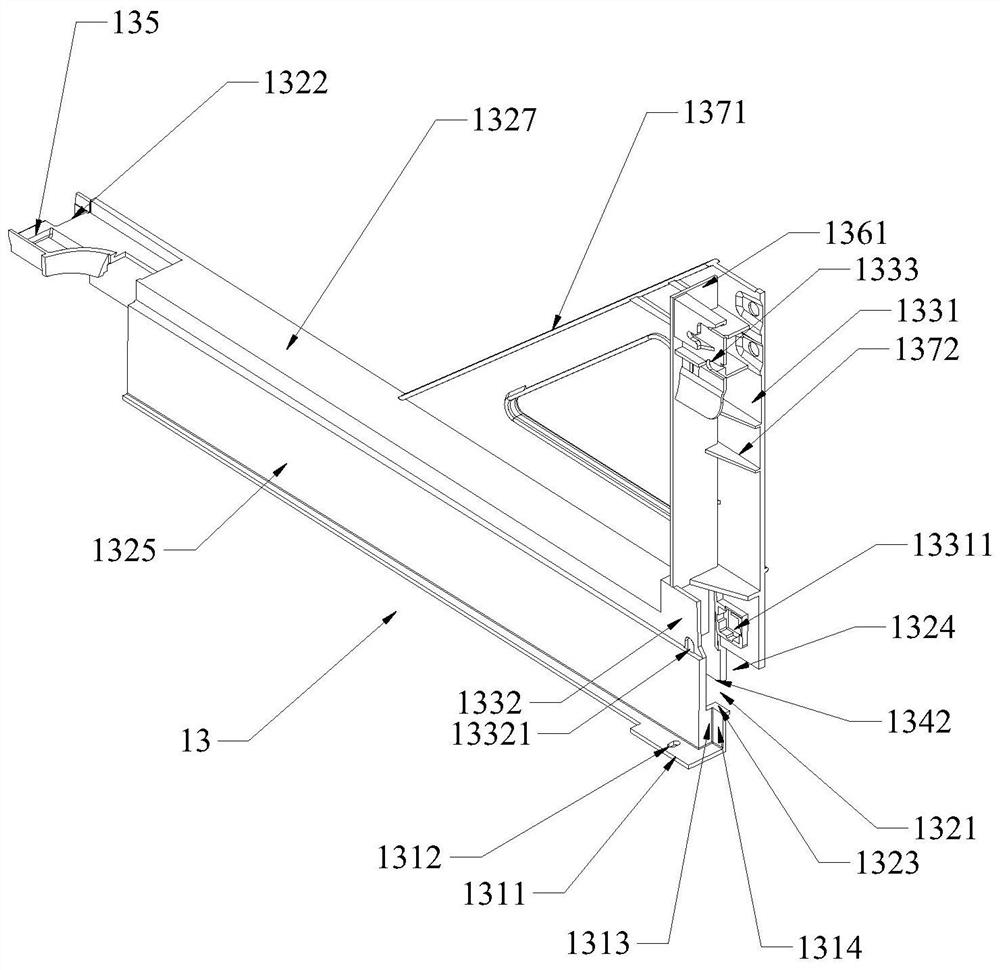

[0048] This embodiment mainly elaborates in detail the specific structure of the supporting structure and assembly structure of the supporting device and the bottom bracket, as well as the assembly relationship between the supporting device and the bottom bracket.

[0049] The following is a detailed description of the supporting structure of the supporting device and the assembly structure of the bottom bracket.

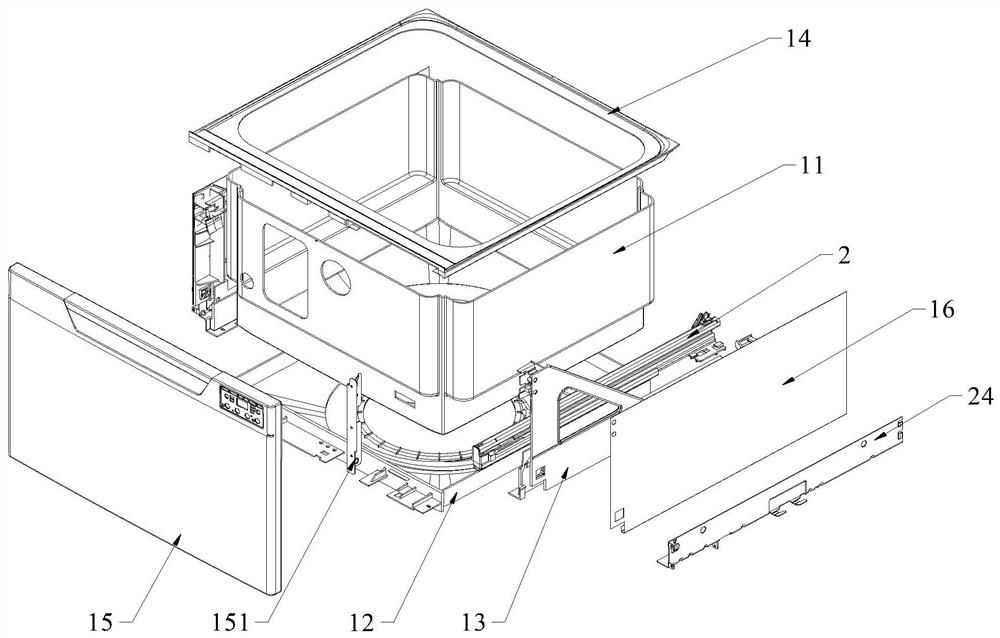

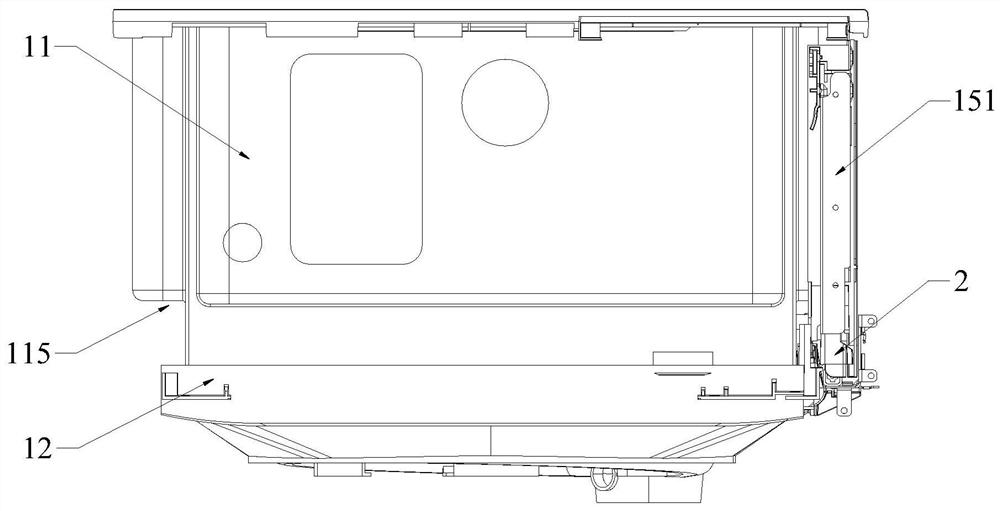

[0050] combine Figure 1 to Figure 4 , the bottom of the inner tank 11 of the dishwasher is provided with a bottom bracket 12, the bottom bracket 12 is used to support the inner tank 11, and supporting devices 13 are arranged on both sides of the bottom bracket 12, and the supporting devices 13 are symmetrically arranged on the bottom bracket The both sides of 12, produce symmetrical supporting force to bottom support, to guarantee the stability of liner. Slide rails 2 can be installed on the bottom of the support device. After the slide rails are installed, the li...

Embodiment 2

[0081] This embodiment mainly introduces in detail the specific structure of the assembly structure of the slide rail in which the supporting device cooperates with the slide rail, and its assembly relationship with the slide rail.

[0082] The following is a specific description of the slide rail assembly structure of the support device:

[0083] Such as Figure 8 to Figure 10 As shown, the support device provided by this embodiment includes a support body with an extended length, the support body has an assembly structure, and the assembly structure includes a slide rail assembly structure, and the slide rail assembly structure is arranged under the support body The slide rail installation position; preferably, the slide rail installation position is a slide rail installation slot 1321 penetratingly provided under the supporting body. The slide rail installation groove 1321 is a concave groove, the opening of the concave groove is downward, and the shape of the inner wall o...

Embodiment 3

[0106] This embodiment mainly introduces in detail the specific structure of the door body assembly structure in which the support device cooperates with the door body, and its assembly relationship with the door body.

[0107] The following is a specific description of the door body assembly structure of the support device:

[0108] In this embodiment, the support device in this embodiment includes a support body with an extended length, the support body has an assembly structure, and the assembly structure includes a slide rail assembly structure. Such as Figure 9 to Figure 11 As shown, the supporting body includes the first supporting frame described in the second embodiment, and a second supporting frame fixedly connected to one end of the first supporting frame, and the second supporting frame includes a A longitudinal plate on one end, the door assembly structure is arranged on the longitudinal plate. The door body assembly structure provided on the supporting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com