A polytetrafluoroethylene impurity removal filter matrix for brine

A teflon, salt water technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve problems such as the balance of loss compensation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

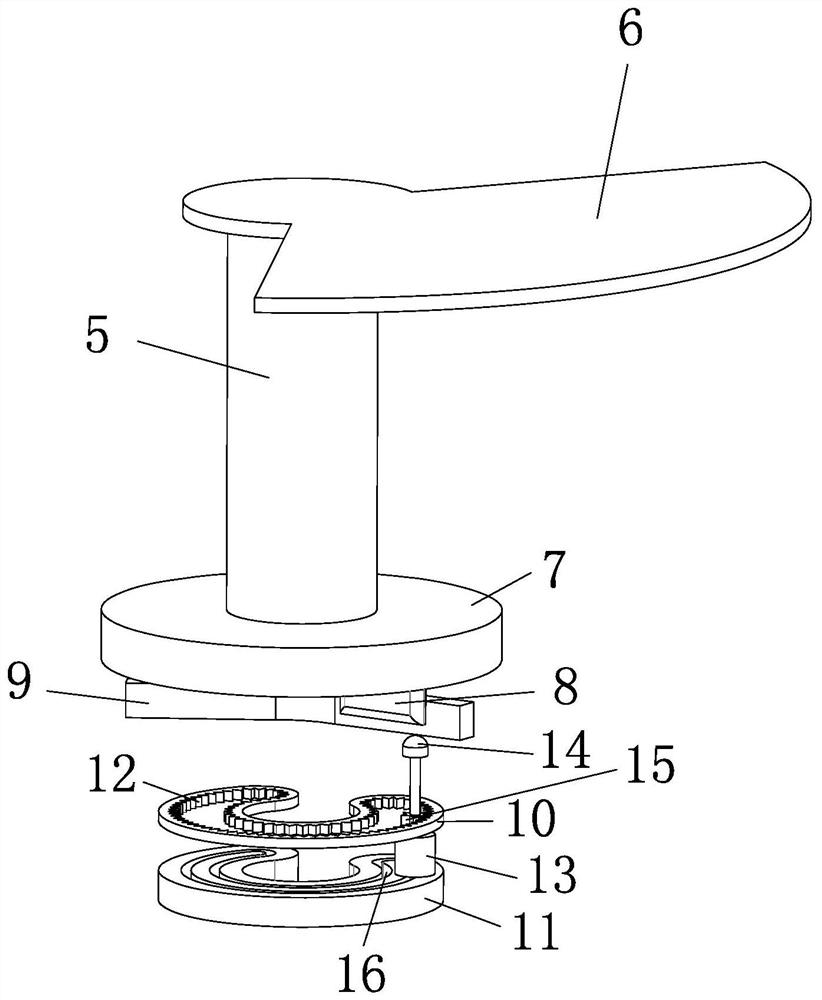

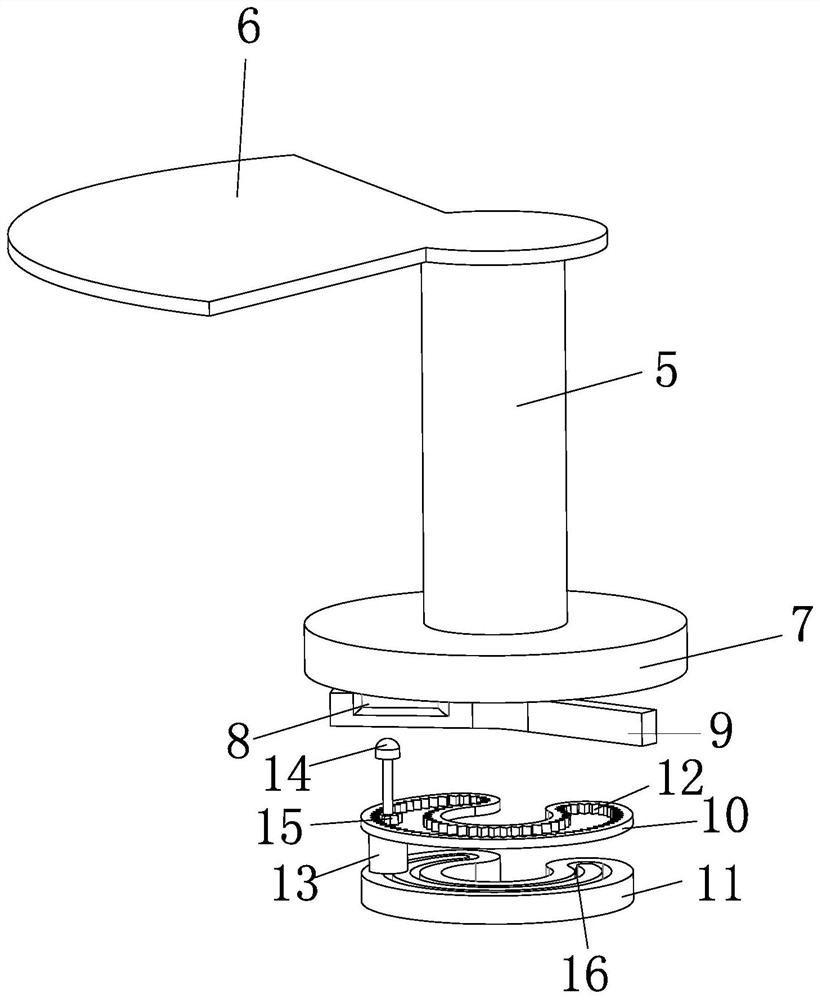

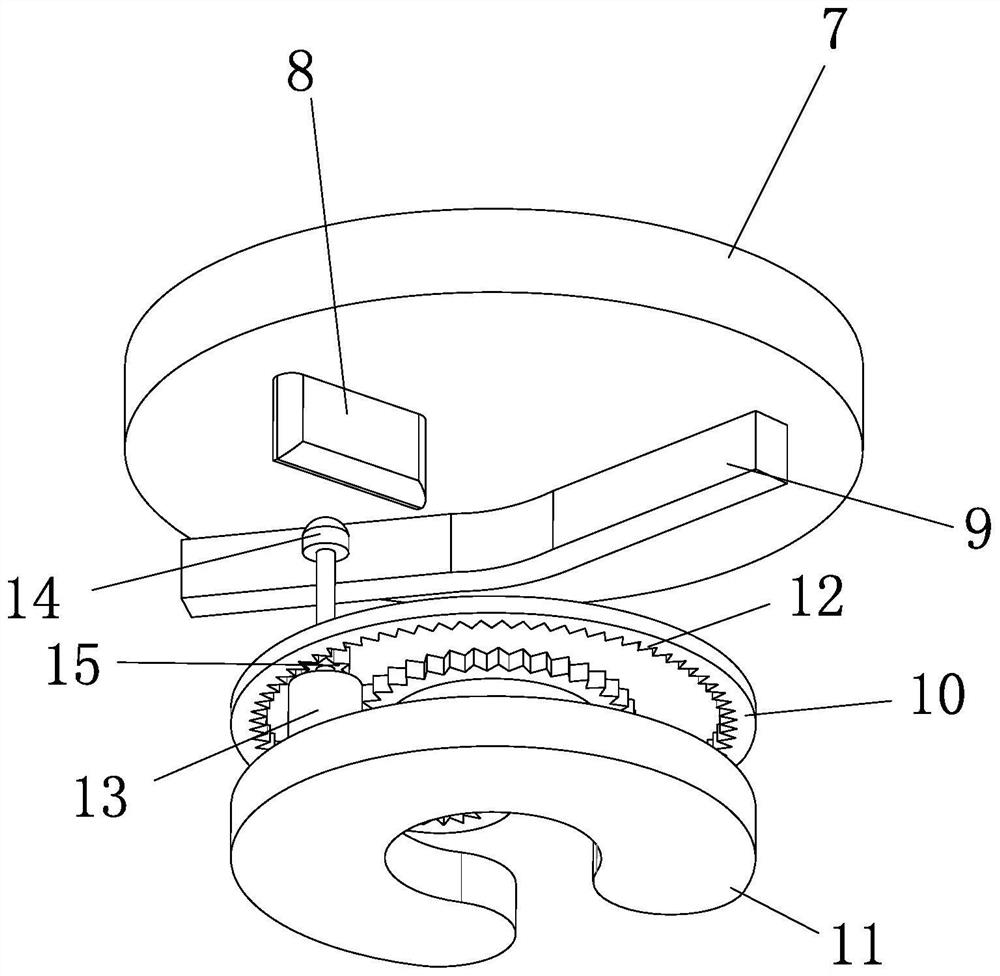

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] Such as Figure 7 As shown, the polytetrafluoroethylene impurity-removing filter matrix of the brine includes a filter body 1 with an inlet 2 above and an outlet below, a filter plate fixed on the outlet of the filter body 1, and a filter plate fixed inside the filter The heating and sterilizing part in the chamber, the inlet 2 is used to pour the raw material liquid, and the outlet is used to discharge the raw material liquid after the impurities will be isolated. There is a shaft hole 3 beside the inlet 2 of the filter tank body 1, and the inlet 2 of the filter tank body 1 There is a plate-shaped opening 4 on the inner wall, and the plate-shaped opening 4 communicates with the shaft hole 3. The plate-shaped openin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com