Automatic oil-water separation device for sewage treatment

An automatic separation and sewage treatment technology, which is applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve the problems that oil easily contains water and oil is not completely cleaned, and achieves the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

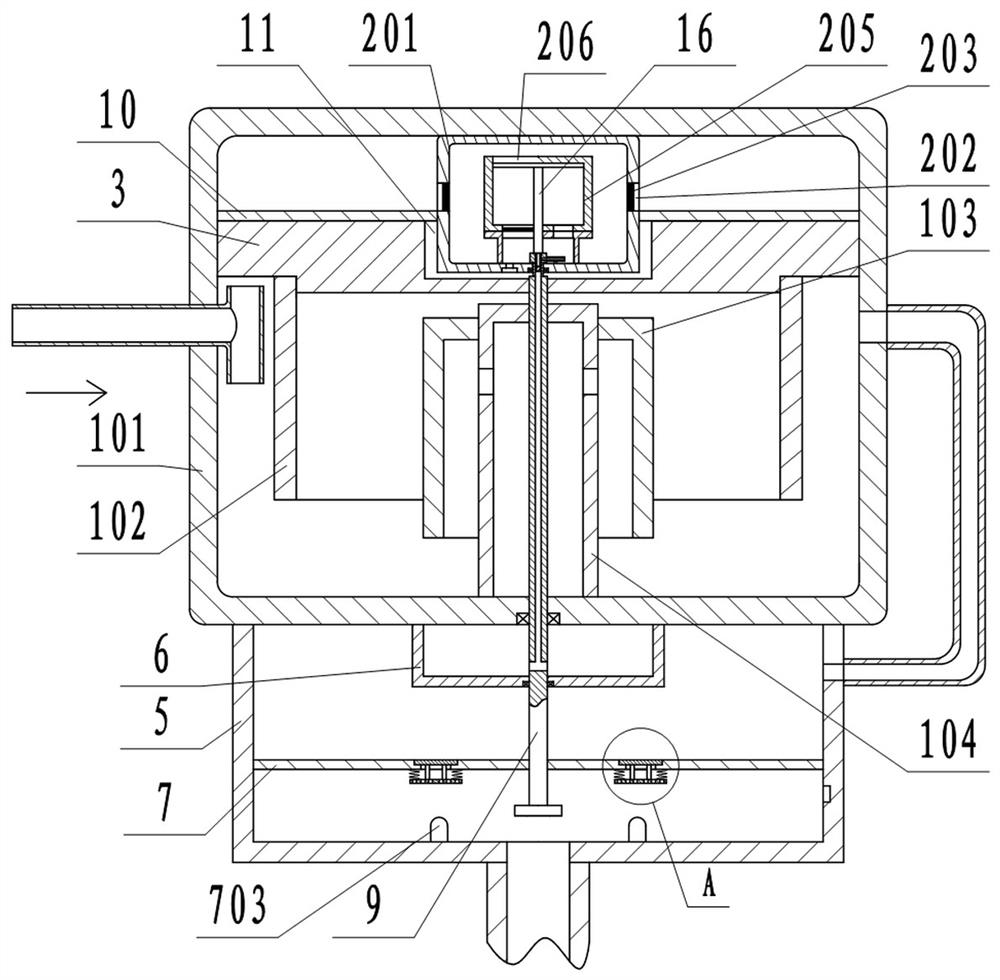

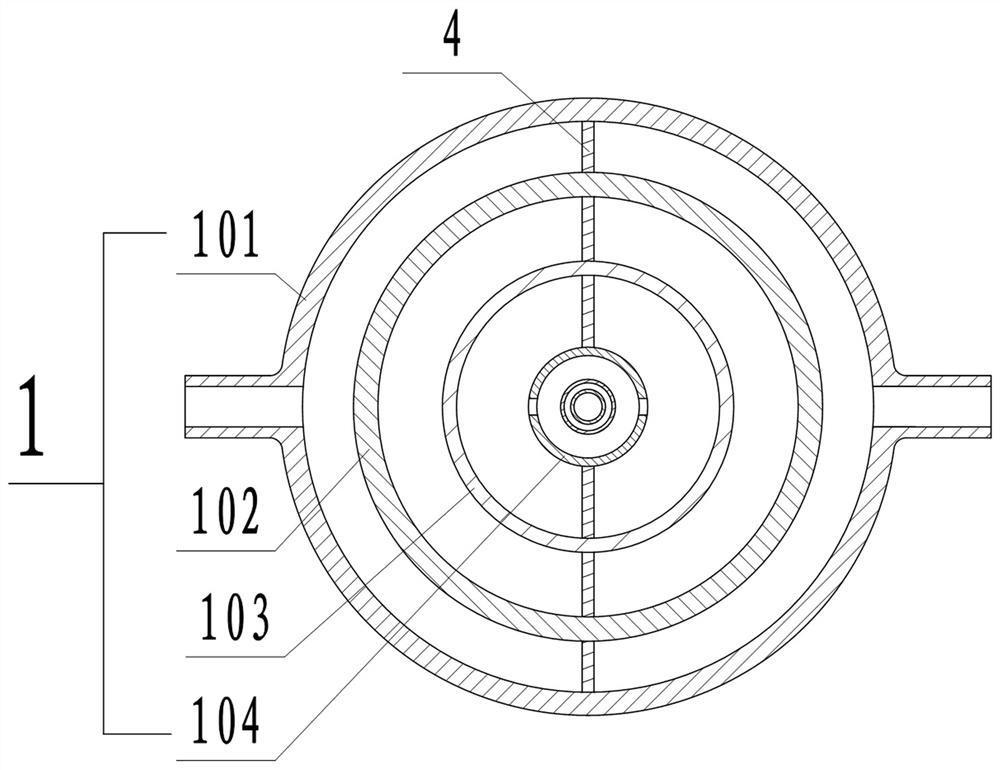

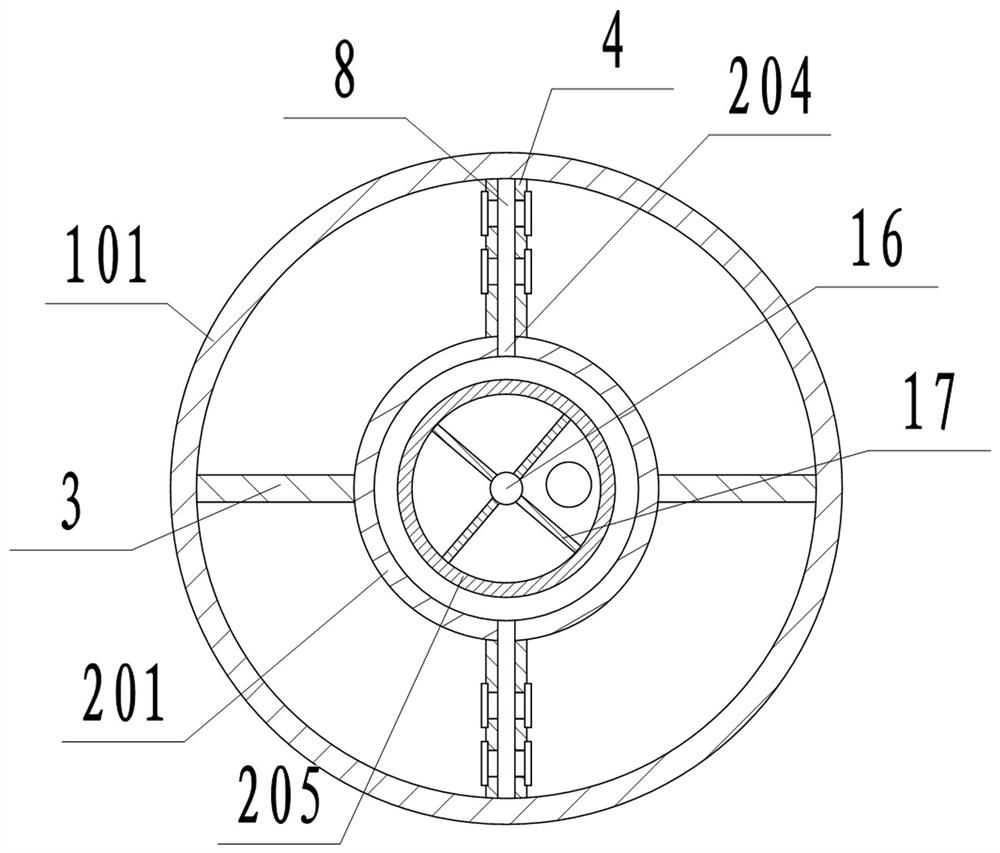

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Depend on Figure 1 to Figure 9 Given, the present invention includes a grease trap 1, an oil filter unit 2, an oil scraper 3, a separator 4, a sump 5 and an oil storage tank 6, and the oil filter unit 2 is located in the grease trap 1 and Close to the top, the partition 4 is located in the middle of the grease trap 1 and placed in the front and rear directions. The partition 4 divides the grease trap 1 into two symmetrical parts. The left and right sides of the partition 4 A liquid passage 8 connecting the grease trap 1 with the oil filter unit 2 is opened on the end face, the water collection pool 5 is located below the grease trap 1, and the water collection pool 5 is provided with a The water baffle 7 that moves up and down, the water baffle 7 divides the sump 5 into two independent chambers up and down, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com