Drug synthesis device based on different reaction parameters

A technology of drug synthesis and parameters, applied in lighting devices, lighting devices, chemical/physical/physical-chemical processes of applying energy, etc., can solve the problems of low use efficiency, inability to apply drug reaction conditions, and inability to modify reaction parameters, etc. Simplified structure, reduced sealing requirements, simplified effect of heating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

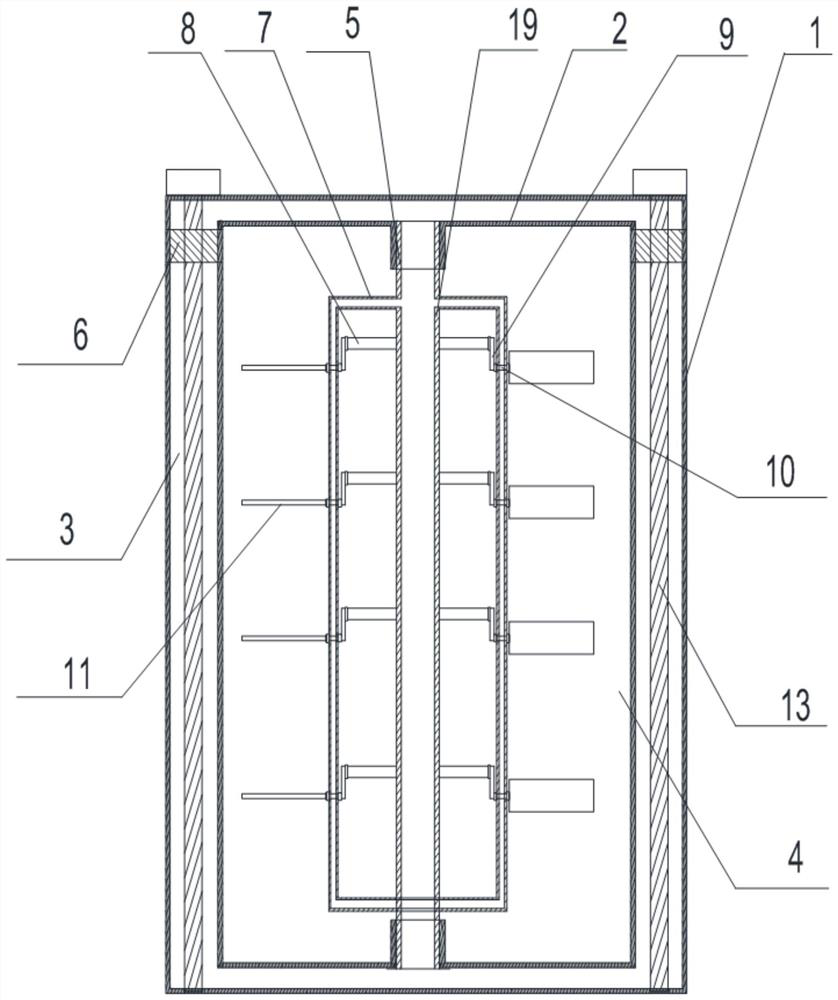

[0036] The device includes a device body 1, such as figure 1 As shown, the device body 1 is provided with a partition plate 2, and the partition plate 2 divides the inside of the device body 1 into a stirring layer 4 and an adjustment layer 3 from the inside to the outside. The stirring layer 4 is set in the adjustment layer 3, and the stirring layer 4 is provided with a stirring rod 5, the inside of the stirring rod 5 is a cavity, and the upper and lower ends of the stirring rod 5 are respectively connected with the upper and lower ends of the adjustment layer 3; Rod 13, two adjustment rods 13 are respectively positioned at the both sides of stirring rod 5, two adjustment rods 13 are threadedly connected with an adjustment plate 6 respectively, the upper ends of two adjustment rods 13 pass through the top of the device body and are connected with a motor, The two adjustment rods rotate along their straight line under the action of the motor, and the adjustment plate on the ad...

Embodiment 2

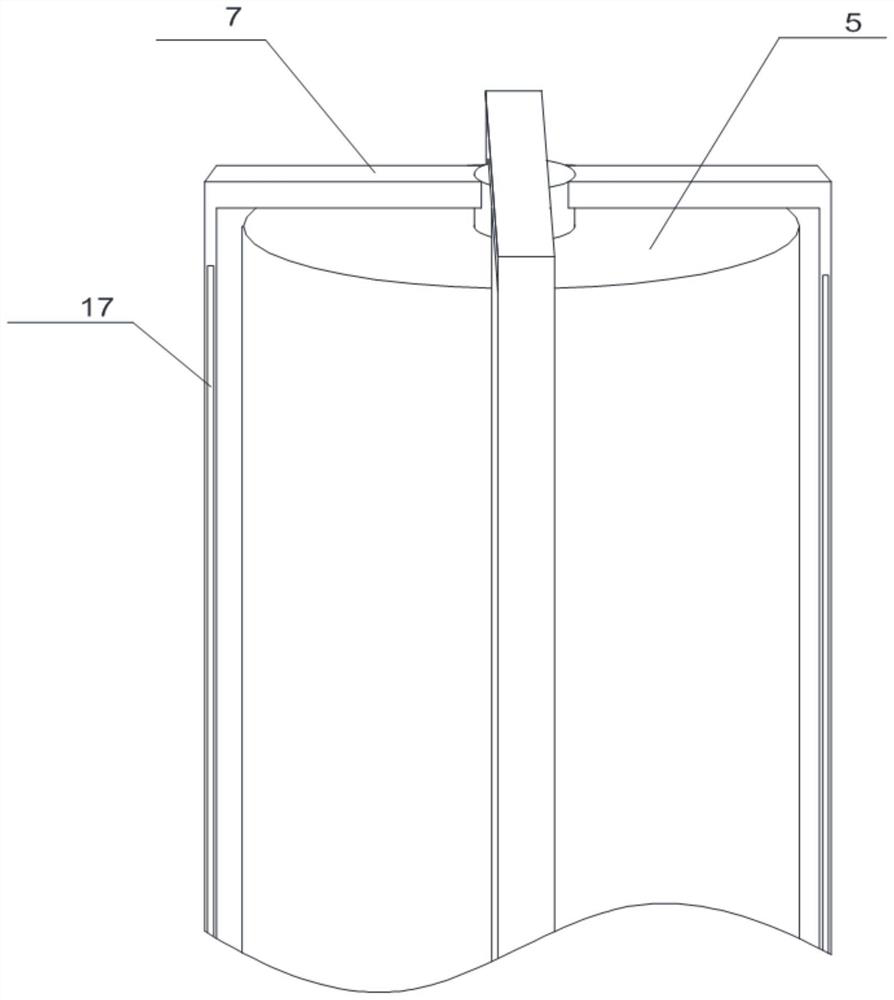

[0040] On the basis of Example 1, such as figure 1 As shown, the stirring rod 5 includes a support column 19, a rotating column 7 and a stirring sheet 11, and in this embodiment the structure of the stirring rod is as figure 2 As shown, the rotating column is U-shaped, and there are four rotating columns in this embodiment. When in use, the rotating column rotates on the supporting column, and the supporting column does not rotate. At the same time, the stirring blade is connected to the rotating column, and the rotating column drives Stirring plate rotates together, and the upper and lower ends of supporting column 19 communicate with the upper and lower ends of adjustment layer 3 respectively, the inside of rotating column 7 communicates with the inside of supporting column 19, and the inside of stirring plate 11 communicates with the inside of rotating column 7, so When stirring, if the reaction is carried out at normal temperature, the water flowing in the stirring plate ...

Embodiment 3

[0043] On the basis of Example 2, such as Figure 6 As shown, the rotating column 7 includes two side plates parallel to each other and a base plate perpendicular to the side plates, the base plate and the support column 19 are parallel to each other, the two ends of the base plate are vertically connected with a side plate respectively, and the first connecting rod 10 is perpendicular to the base plate connection, the two opposite sides of the bottom plate are provided with lighting boards 14, the lighting boards 14 are located on both sides of the side boards, the lighting board 14 is provided with a placement groove 18, and an LED lamp board is placed in the placement groove 18, and the LED lamp board structured as Figure 7 As shown, the LED lamp board includes an LED lamp 17 and two fixing plates 15, and the two fixing plates 15 are respectively connected to the two ends of the LED lamp 17 through threads, and a lifting rope 16 is arranged on the top of one of the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com