A regulator capable of fine-tuning water mixing and well flushing control for energy saving and consumption reduction

A regulator and fine-tuning technology, applied in the field of regulators, can solve the problems of easy freezing, high manufacturing cost, complex structure, etc., and achieve the effects of uniform and continuous adjustment, improved adjustment accuracy, and simple heating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

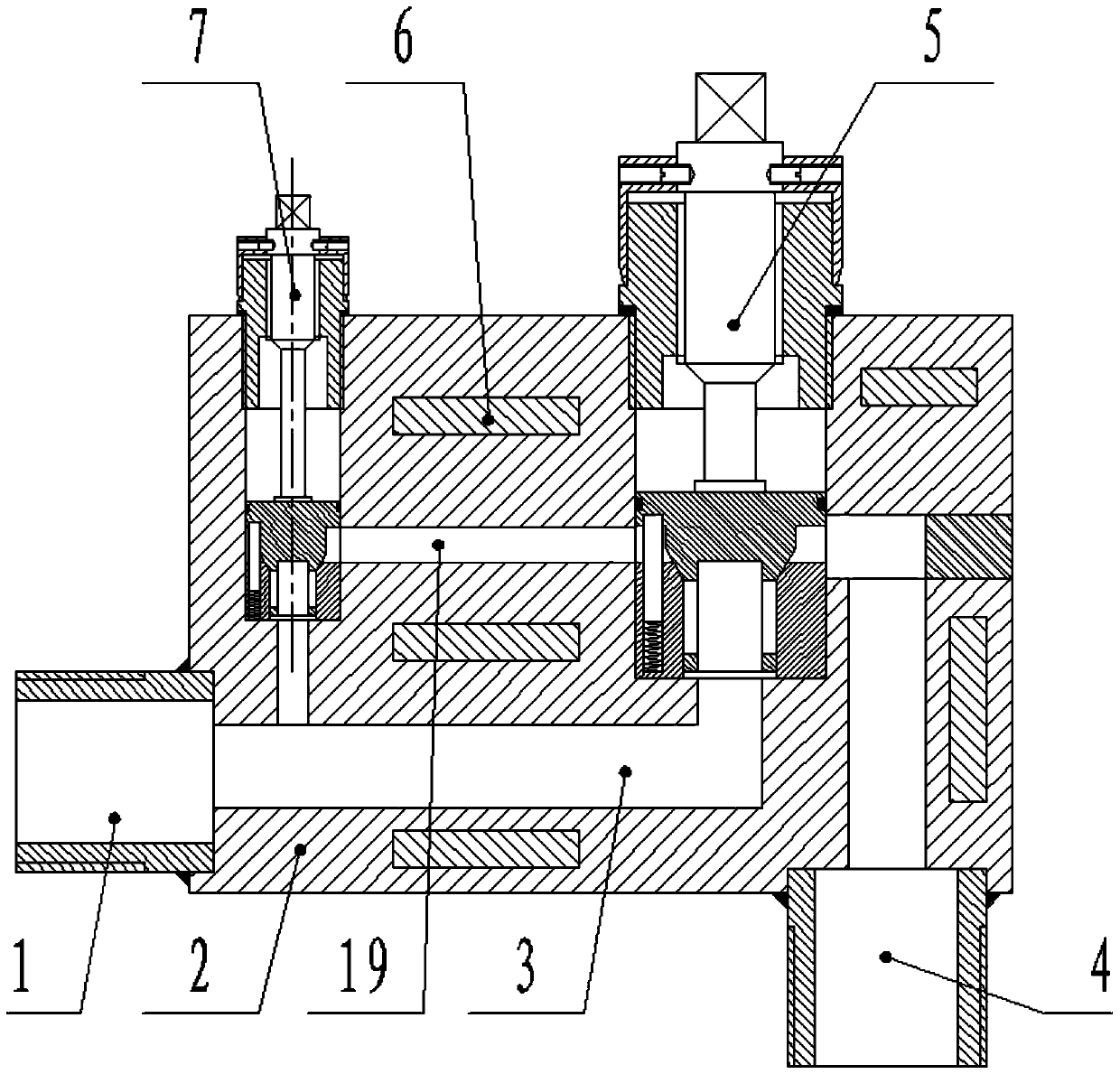

[0021] The present invention will be further described below in conjunction with accompanying drawing:

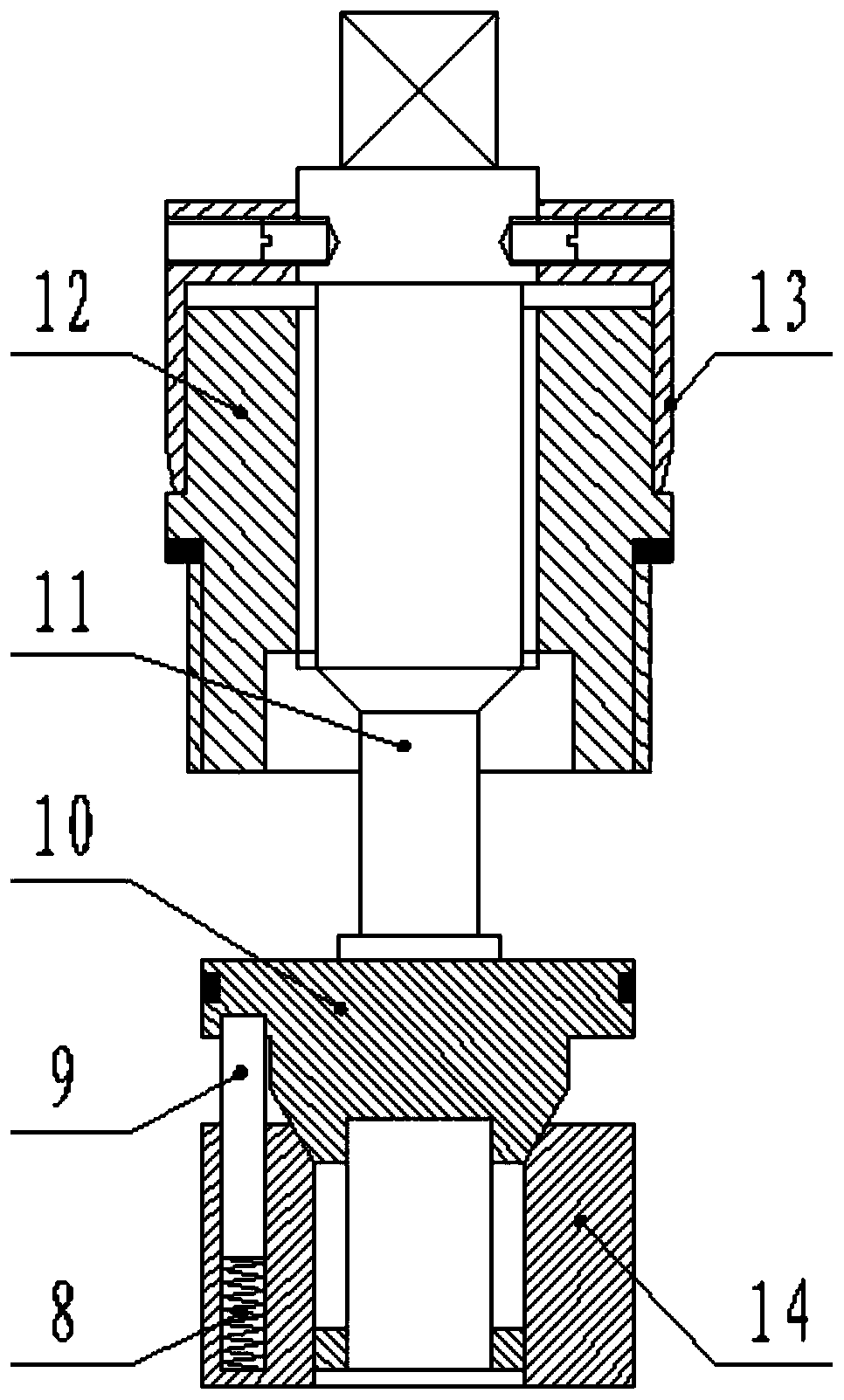

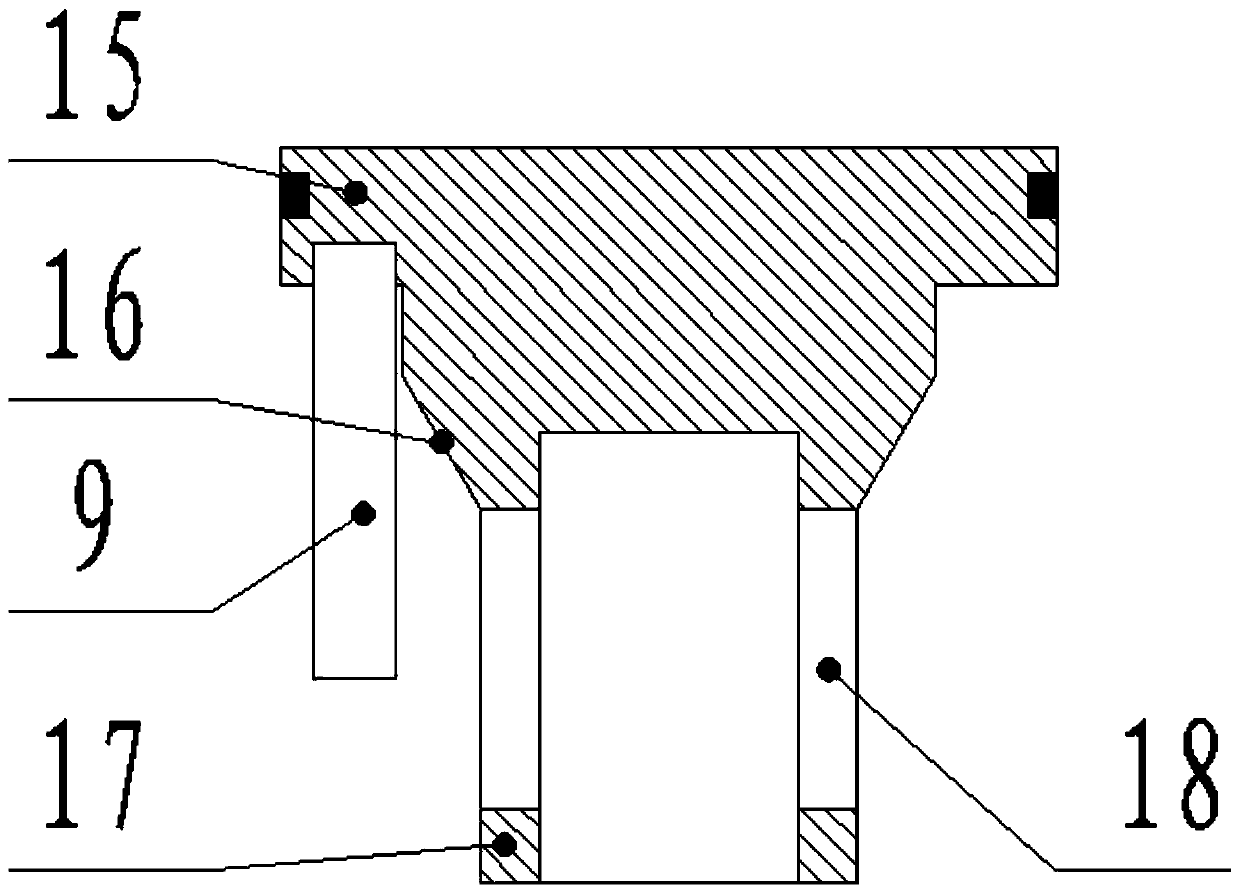

[0022] This embodiment includes a valve body 2 and a valve assembly. The valve assembly is installed on the valve body 2. The valve assembly includes a valve stem 11, a valve core 10 and a valve seat 14. The valve core 10 approaches or moves away from the valve seat under the drive of the valve stem 11. 14, thereby realizing the switch of the valve assembly. The above are common structures in the prior art, and will not be repeated here.

[0023] In the prior art, the valve body of the water mixing valve is mostly made of cast iron, and the cast iron material is easy to rust, which seriously affects the service life of the water mixing valve. In the present invention, the outer contour of the valve body 2 is a cubic structure , During specific implementation, the valve body 2 can be processed from a cubic stainless steel blank.

[0024] The valve stem 11 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com