Method for guiding smelting process by determining relative carbon-content in solid sample of Electro-thermal method smelting aluminum silicon alloy

A technology of aluminum-silicon alloy and solid sample, applied in the direction of weighing by removing certain components, electrical digital data processing, special data processing applications, etc., can solve the problem that industrial analysis methods are not enough to achieve accurate control, and the production process has poor guidance , rough measurement results and other problems, to achieve high industrial application value, easy to master, simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

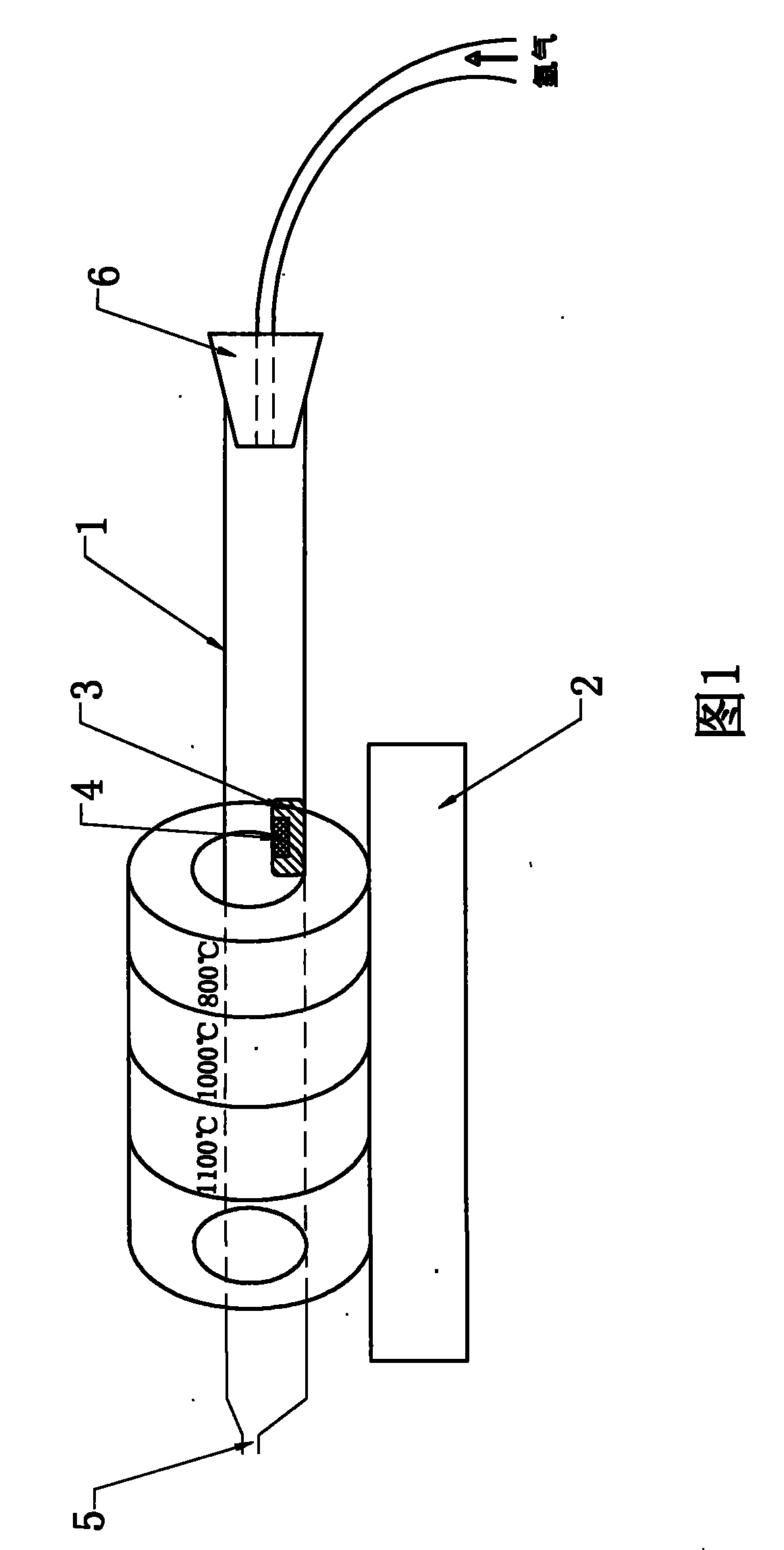

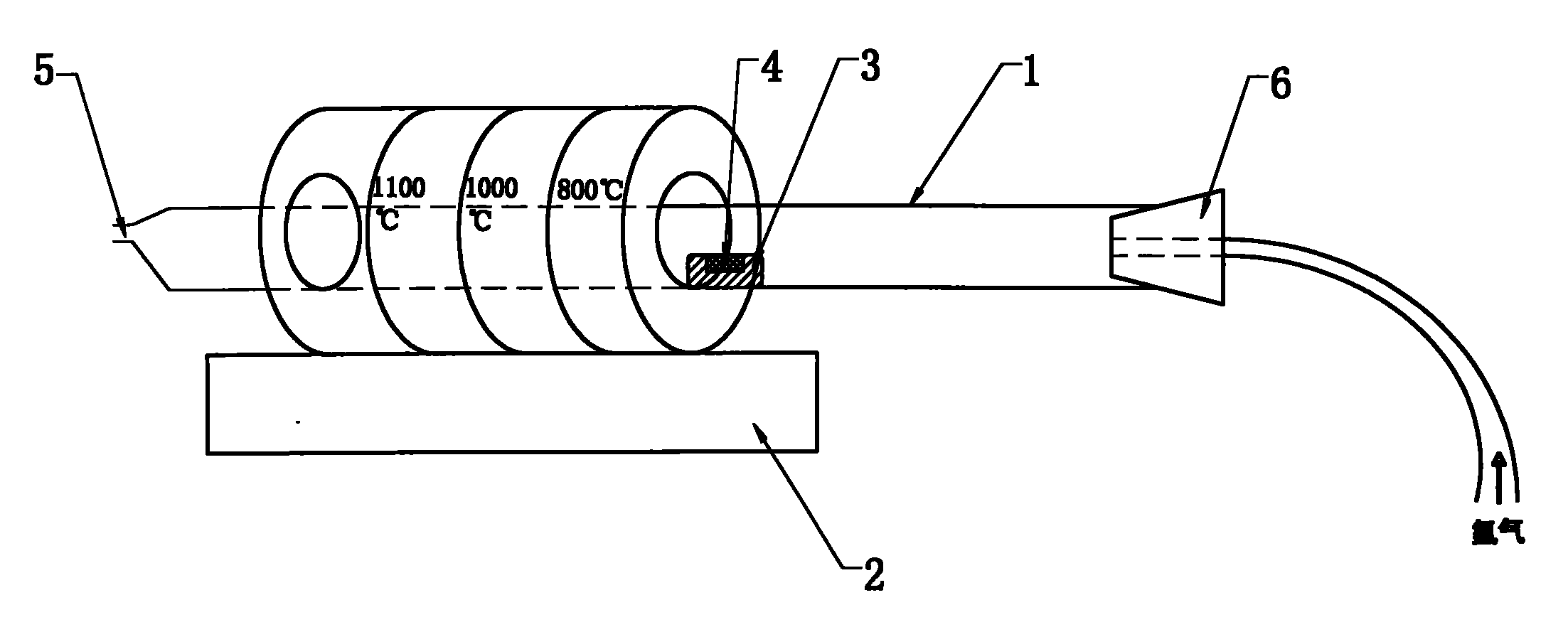

[0038] refer to figure 1 A method for guiding the smelting process by measuring the relative carbon content in a solid sample of aluminum-silicon alloy smelted by electrothermal method, comprising the steps of:

[0039] (1) A quartz tube 1 with a diameter of 50 mm, the front end of the quartz tube 1 is a capillary joint 5, and the length of the capillary joint 5 is 40 mm; Out of electric furnace 200mm;

[0040] (2) heating the tubular electric furnace 2 into three temperature zones of 800°C, 1000°C, and 1100°C and keeping it stable;

[0041] (3) The porcelain boat 3 was calcined to a constant weight at 1100°C, and the sample 4 to be tested was dried to a constant weight at 110°C with a moisture analyzer;

[0042] (4) Inert gas argon is passed through a piston at the rear end of the quartz tube 1, and a pressure reducing valve is used to adjust the gas delivery rate so that the gas intake is constant during the whole process;

[0043] (5) Put the sample 4 into the porcelain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com