Production method for shielding case

A production method and technology of shielding cover, applied in the field of shielding cover production, can solve the problems such as the influence of the production yield of the shielding cover, difficult separation of adhesion, scratches, etc., so as to avoid mutual scratches, improve the processing efficiency, and improve the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

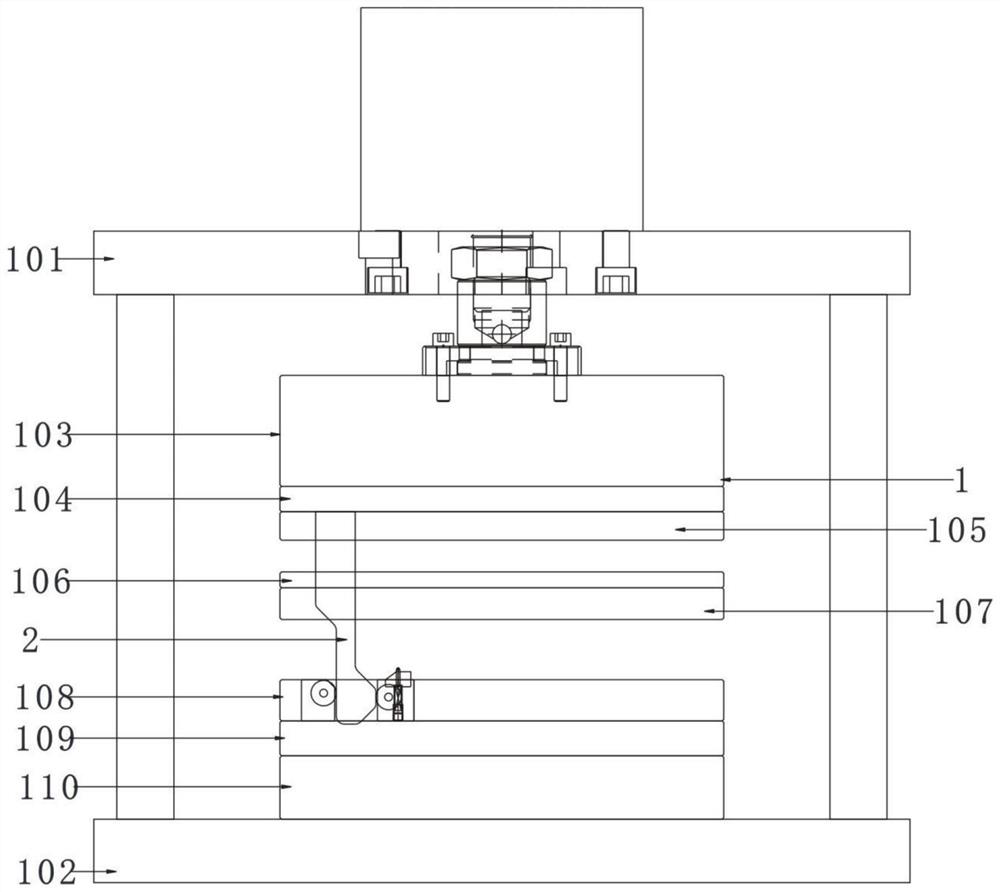

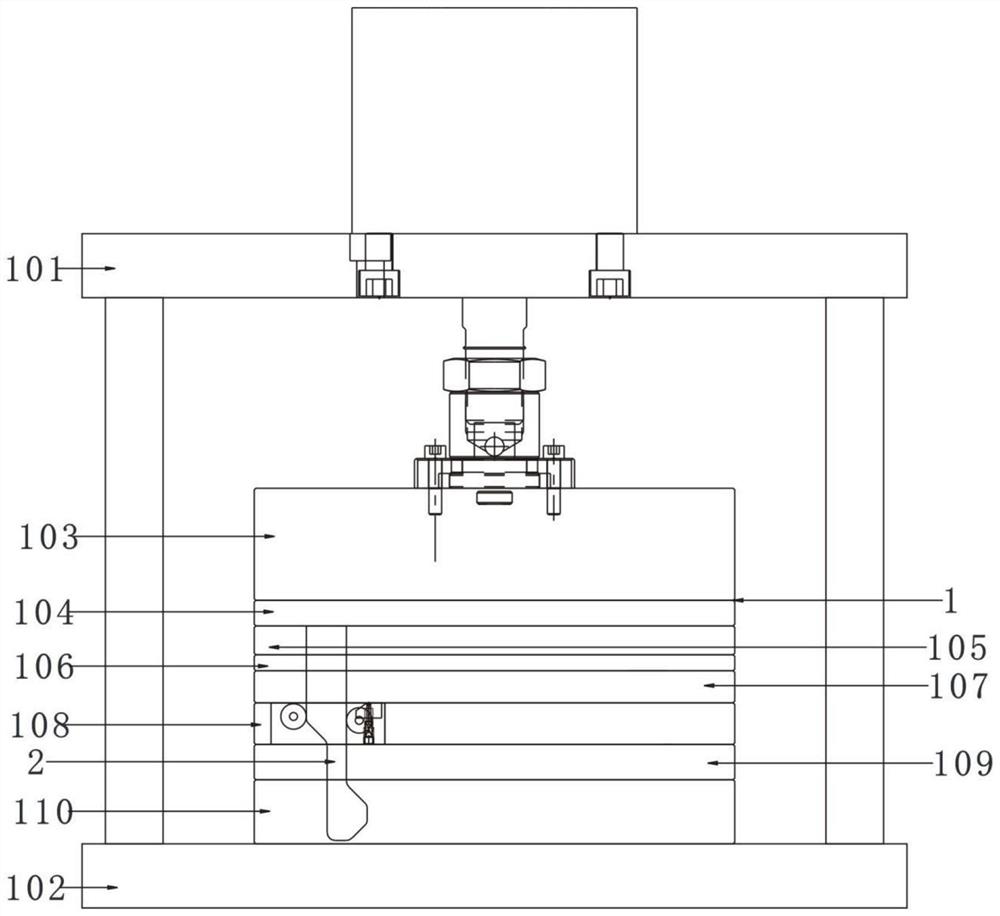

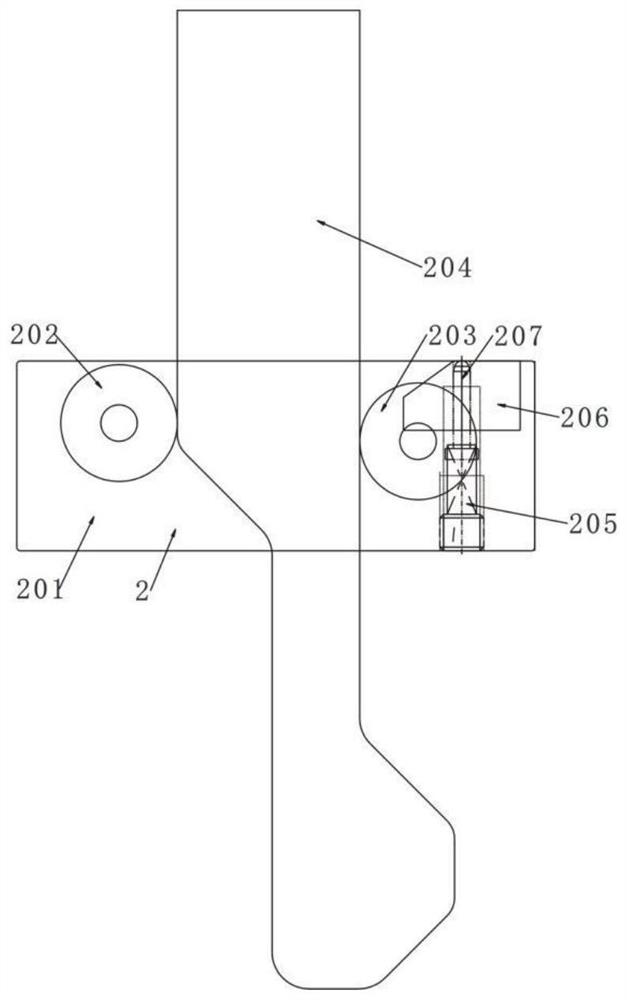

Image

Examples

Embodiment 1

[0042] A method for producing a shielding case. It includes the following steps:

[0043] 1) The first stamping: the raw material is formed into a shielding cover through the middle of the continuous stamping die, and at the same time, the two sides of the raw material are formed into a strip through the continuous stamping die, forming an overall structure in which the shielding cover is located on the strip. That is to say, the raw material is formed into a shielding cover through a continuous stamping die, and the shielding cover is left on the raw material. At this time, the shielding cover and the raw material are still in an integrated structure. The structure of the cover, the process in this step is the preliminary processing of the raw materials to form the raw materials for subsequent processing.

[0044]2) Cleaning: The raw materials of the shielding cover are arranged on the material belt, and enter the cleaning tank for cleaning; the function of cleaning is to cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap