Automobile chassis noise reduction device

An automobile chassis and noise reduction technology, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of sound insulation, shock absorption, poor noise reduction effect, lack of protective structure, poor installation and fixability, etc., and achieve overall firmness and stability, disassembly Simple and convenient, the effect of firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

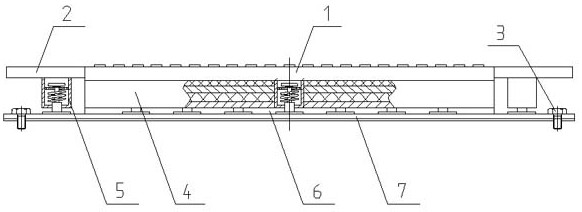

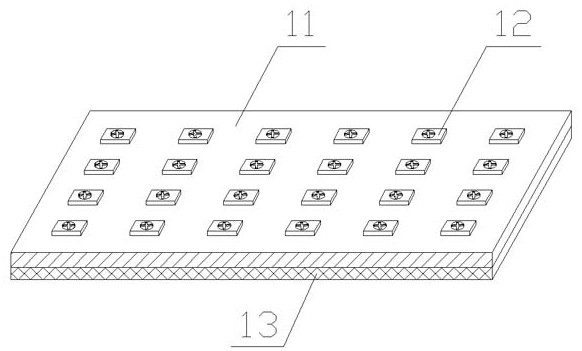

[0028] Embodiment 1: A kind of automobile chassis noise reduction device provided by the present invention comprises a top connecting plate 1, a mounting support plate 2, bolts 3, a noise reduction partition 4, a shock absorbing column 5, a buffer pad 6 and a protective bottom plate 7, wherein : the side of the top connecting plate 1 is integrally welded with a mounting support plate 2, the protective base plate 7 is provided with bolts 3, and the protective base plate 7 is fixedly installed with the automobile chassis through the bolts 3; the noise reduction partition 4 is welded on the top connection The lower part of the plate 1, and the lower part of the noise reduction partition 4 is fixed by a buffer pad 6 by screws, and the lower part of the buffer pad 6 is fixed by a protective bottom plate 7; , and the lower end of the shock-absorbing column 5 is welded and fixed to the upper side of the protective bottom plate 7; the top connecting plate 1 includes a contact plate 11,...

Embodiment 2

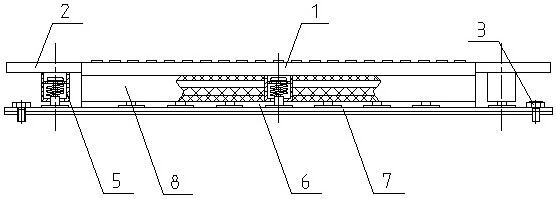

[0031] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the noise reduction partition 4 in embodiment 1 is replaced by a vacuum sound insulation board 8. In addition to the sound insulation layer 43, the vacuum sound insulation board 8 is also provided with an airtight A cavity 81, and the cavity is in a vacuum state; a check valve 82 is provided outside the vacuum sound insulation board 8, and the check valve 82 communicates with the cavity 81, and the check valve 82 is connected with external vacuum equipment. As we all know, since the sound cannot be retransmitted in a vacuum, the vacuum sound insulation panel 8 can more effectively isolate the chassis noise, and the shock-absorbing column 5 can not only reduce the noise generated by bumps, but also slow down the intensity of sound waves. effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com