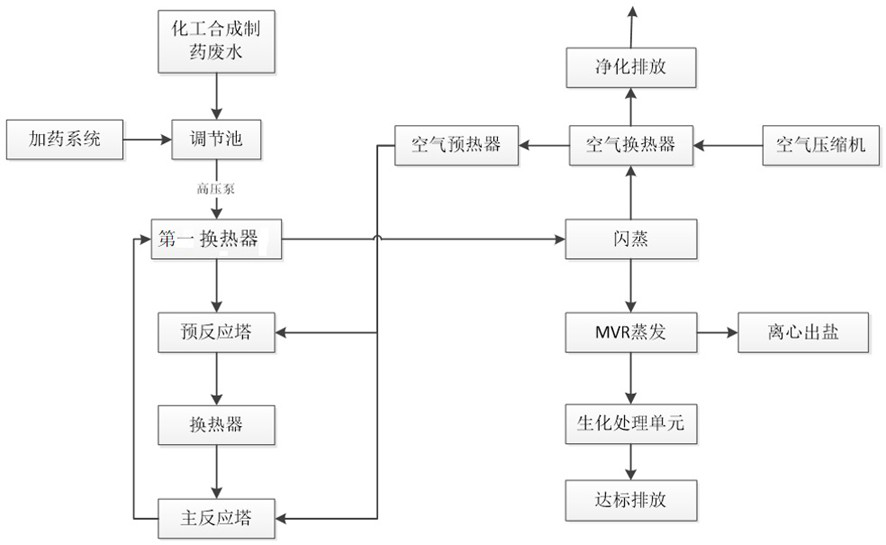

A cwo and mvr combined wastewater pretreatment system and a pretreatment method

A technology for pretreatment and wastewater, applied in the fields of neutralization water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, difficulty and poor effect of chemical synthesis pharmaceutical wastewater pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] (T1) Add 20 parts of halloysite nanotubes to the mixed acid of hydrochloric acid and nitric acid, the concentration of hydrochloric acid in the mixed acid is 3M, the concentration of nitric acid is 2M, ultrasonically disperse for 0.5h, and then add 1 part of silane coupling agent KH-550 , continue ultrasonic dispersion;

[0053] (T2) Add 50 parts of activated carbon powder to the halloysite nanotube dispersion in step (1), stir at a constant temperature of 70°C for 3h, wash with deionized water until neutral, and dry to obtain halloysite nanotube modified activated carbon Composite carrier;

[0054] (T3) Immerse the halloysite nanotube modified activated carbon composite carrier in an aqueous solution containing 0.7M copper nitrate, 0.2M manganese nitrate, and 0.1M cerium nitrate, add 1M ammonia water under stirring conditions, and immerse at 60°C for 24h , dried at 90°C for 2 hours, preheated at 220°C for 2 hours, and then heated to 520°C for 10 hours at a rate of 10°...

preparation example 2

[0056] Other conditions are the same as in Preparation Example 1, except that the aqueous solution in step (T3) is 1M copper nitrate, ie does not contain manganese nitrate and cerium nitrate.

preparation example 3

[0058] The other conditions are the same as in Preparation Example 1, except that step (T3) does not carry out preheating, and directly heats up to 520° C. for 10 h at a heating rate of 10° C. / min after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com