Environment-friendly polymer composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of environmentally friendly polymer composite materials and their preparation, can solve problems such as poor performance stability, poor processing fluidity, and large amount of filler addition, and achieve low preparation costs and high promotion. Application value, improvement of comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

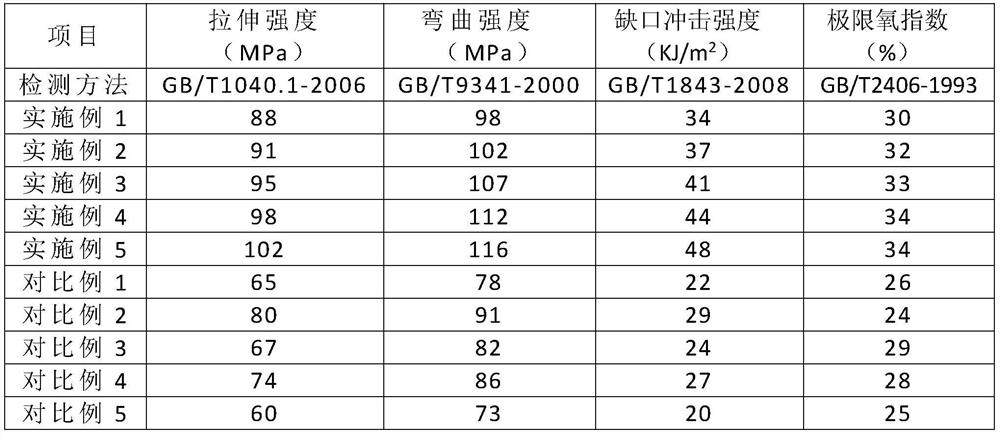

Examples

Embodiment 1

[0025] A preparation method of an environment-friendly polymer composite material, characterized in that it comprises the following steps:

[0026]Step S1, preparation of 3,3'-diamino-4,4'-difluorodiphenylsulfone / 2,3,5,6-tetrafluoroterephthalic acid polycondensate: 3,3'-diamino- 4,4'-Difluorodiphenylsulfone and 2,3,5,6-tetrafluoroterephthalic acid were added to a high boiling point solvent, reacted at 170°C for 2 hours under normal pressure, and then added 1-ethyl-( 3-dimethylaminopropyl) carbodiimide hydrochloride, 4-dimethylaminopyridine, be warming up to 210 ℃, primary polycondensation reaction 5-7 hours, then the reaction solution was transferred into the reactor, replaced with nitrogen The air in the kettle was evacuated to 500Pa, heated to 250°C, polycondensed for 8 hours, cooled to room temperature, and precipitated in water. 3,3'-Diamino-4,4'-difluorodiphenylsulfone / 2,3,5,6-tetrafluoroterephthalic acid polycondensate;

[0027] Step S2, the preparation of 4-acryloylox...

Embodiment 2

[0035] A preparation method of an environment-friendly polymer composite material, characterized in that it comprises the following steps:

[0036] Step S1, preparation of 3,3'-diamino-4,4'-difluorodiphenylsulfone / 2,3,5,6-tetrafluoroterephthalic acid polycondensate: 3,3'-diamino- 4,4'-Difluorodiphenylsulfone and 2,3,5,6-tetrafluoroterephthalic acid were added to a high boiling point solvent, and reacted at 175°C for 2.5 hours under normal pressure, and then 1-ethyl-( 3-dimethylaminopropyl) carbodiimide hydrochloride, 4-dimethylaminopyridine, be warming up to 215 ℃, the primary polycondensation reaction is 5.5 hours, then the reaction solution is transferred into the reaction kettle, and nitrogen is replaced in the kettle Air, evacuated to 500Pa, heated to 255°C, polycondensed for 9 hours, cooled to room temperature, precipitated in water, washed 4 times with ethanol, and then rotary-evaporated to remove ethanol to obtain 3, 3'-diamino-4,4'-difluorodiphenylsulfone / 2,3,5,6-tetr...

Embodiment 3

[0045] A preparation method of an environment-friendly polymer composite material, characterized in that it comprises the following steps:

[0046] Step S1, preparation of 3,3'-diamino-4,4'-difluorodiphenylsulfone / 2,3,5,6-tetrafluoroterephthalic acid polycondensate: 3,3'-diamino- 4,4'-Difluorodiphenylsulfone and 2,3,5,6-tetrafluoroterephthalic acid were added to a high-boiling solvent, reacted at 180°C for 3 hours under normal pressure, and then added 1-ethyl-( 3-dimethylaminopropyl) carbodiimide hydrochloride, 4-dimethylaminopyridine, be warming up to 220 DEG C, the primary polycondensation reaction was carried out for 6 hours, then the reaction solution was transferred into the reaction kettle, and nitrogen was replaced in the kettle Air, evacuated to 500Pa, heated to 260°C, polycondensed for 10 hours, cooled to room temperature, precipitated in water, washed 5 times with ethanol, and then rotary-evaporated to remove ethanol to obtain 3, 3'-diamino-4,4'-difluorodiphenylsulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com