Roller washing machine

A drum washing machine and drum bottom technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of space waste, achieve the effect of reducing the volume of the shell and reducing the space occupied in the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

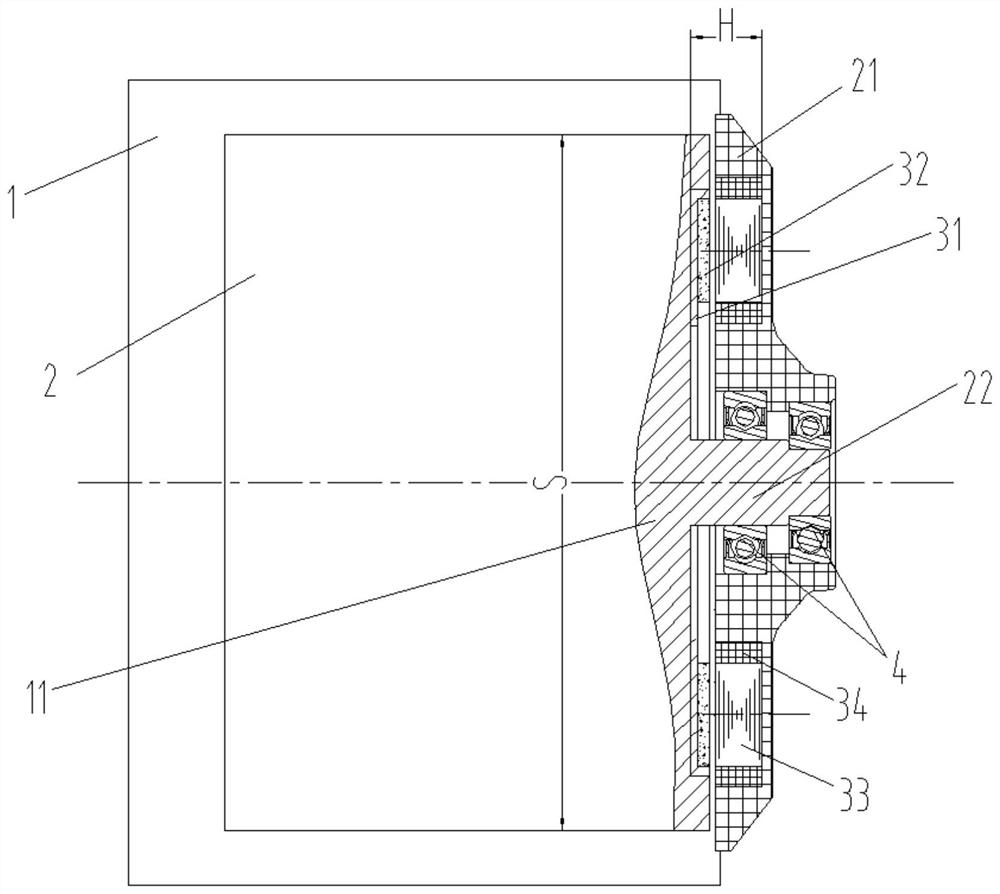

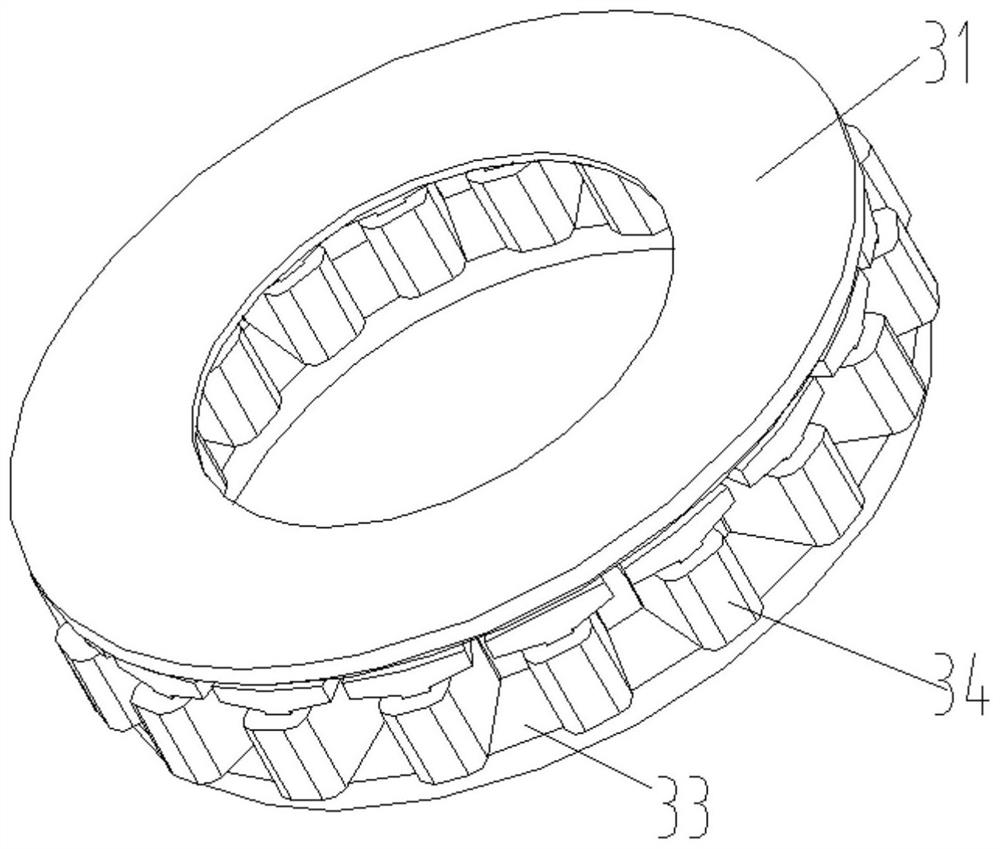

[0021] Combine Figure 1 to 2 As shown, according to an embodiment of the present invention, a roller washing machine includes a tub 1 and an inner barrel 2 in which the outer tub 1 contains a space, the bucket of the inner tub 2 and the bucket of the outer tub 1. Pivot connection between the bottom wall, further comprising an axial magnetic flux motor for driving the inner tub 2 to generate a rotation with respect to the outer tub 1, the axial magnetic flux motor comprising a rotor assembly and a stator assembly, wherein the The rotor assembly is disposed on one side of the barrel bottom wall of the inner tub 2 towards the bottom wall of the outer tub 1, the stator assembly is disposed on the bottom wall of the outer tub 1 toward the bottom wall of the inner barrel 2. Side. In this technical solution, an axial magnetic flux motor is used instead of a direct drive motor (DD motor) in the prior art, and since the rotor assembly between the axial magnetic flux motor and the stator as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com