Antiskid precast concrete pavement plate and construction method thereof

A technology of precast concrete and construction method, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, which can solve the problems of hardening the road surface and increasing the friction force of the precast concrete pavement surface, so as to reduce the amount of use and be easy to operate , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

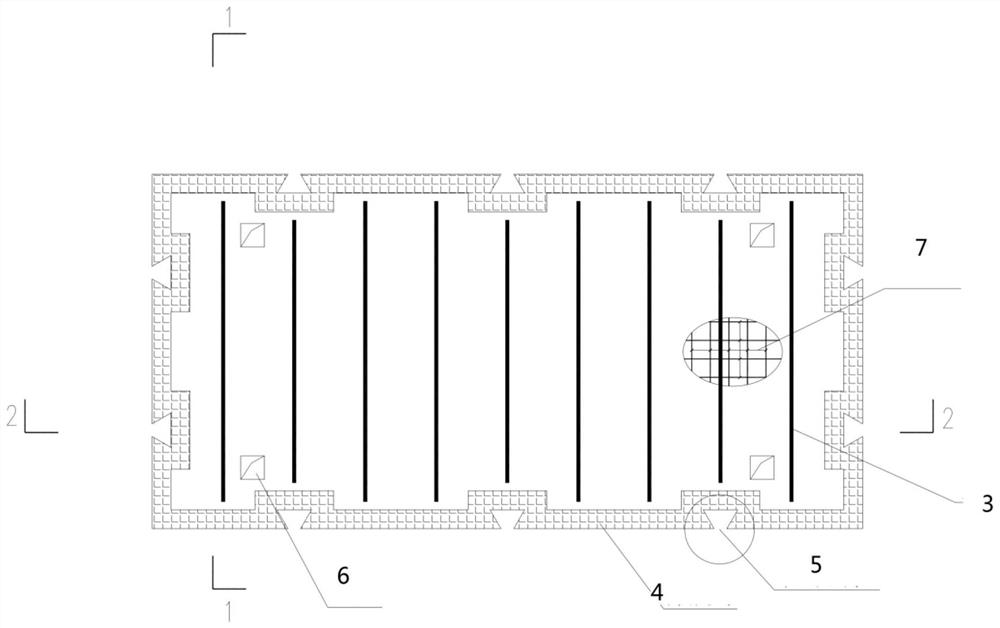

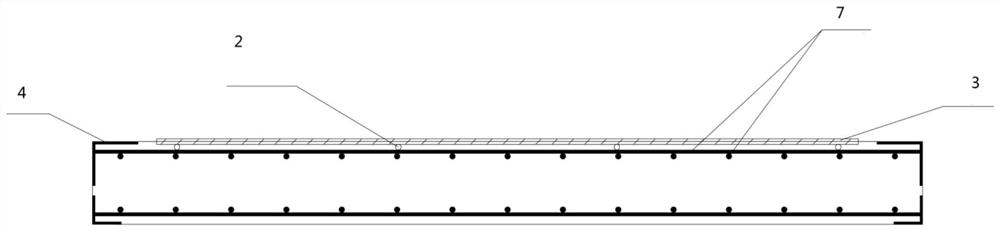

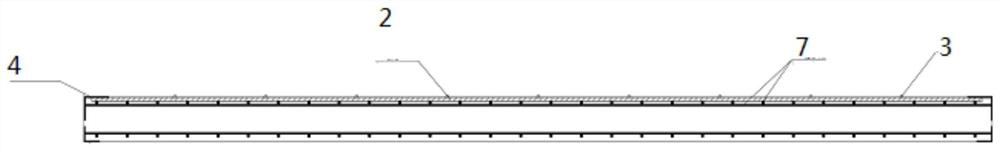

[0034] Combine below Figure 1 to Figure 5 , detailing the structural composition of the anti-skid precast concrete pavement block of the present invention.

[0035] Please refer to Figure 1 to Figure 5 , a non-slip prefabricated concrete road slab block, including a plain soil layer, a graded sandstone layer, a precast concrete road slab, erecting ribs 2 and anti-skid ribs 3 arranged in sequence from bottom to top, and the erecting ribs 2 and anti-skid ribs 3 are crisscrossed The precast concrete road slab is provided with a wrapping layer 4 around it, and the precast concrete road slab is provided with a socket interface 5 around it, and the socket interface 5 is equipped with a connecting block.

[0036] The frictional force on the surface of the precast concrete road slab is increased by adding the reinforced anti-slip rib 3 to the existing precast concrete road slab. In the process of making the precast concrete road slab, first place 4 steel bars with a diameter of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com