Green energy-saving fabricated building wall part

A building wall and energy-saving technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of insufficient support structure, high manual labor intensity, troublesome assembly and disassembly, etc., and achieve simple assembly and disassembly Convenience, labor saving, high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

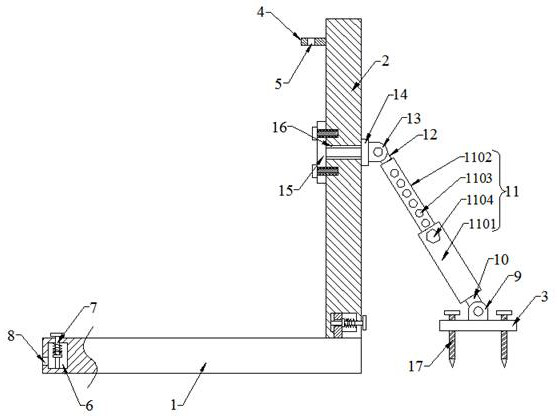

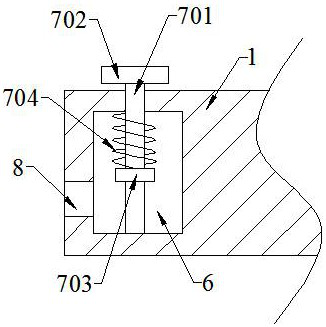

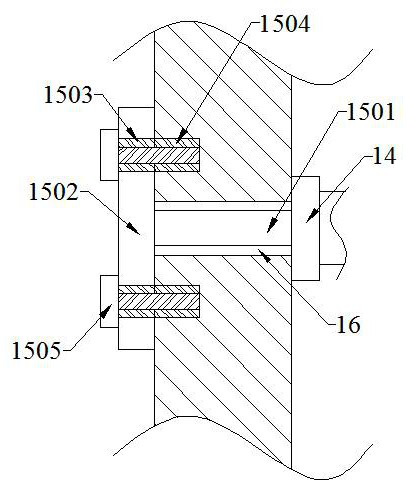

[0028] Please refer to the attached Figure 1-5 As shown, this embodiment is a green energy-saving prefabricated building wall component, including a first assembly wall 1, a second assembly wall 2 and a fixing plate 3, the upper end of the first assembly wall 1 and the second assembly The left end of the wall body 2 is fixedly connected with a plug-in rod 4, and the plug-in rod 4 is provided with a plug-in hole 5, and the left side of the first assembly wall body 1 and the lower side of the second assembly wall body 2 are all provided with a hole. Cavity 6, the interior of cavity 6 is provided with a fixed assembly 7, the left end of the first assembly wall 1 and the lower end of the second assembly wall 2 are provided with a slot 8, the slot 8 communicates with the cavity 5, and the upper end of the fixed plate 3 is fixed Connected with a first connecting piece 9, the upper end of the first connecting piece 9 is hinged with a first connecting rod 10, the upper end of the fir...

Embodiment 2

[0037] Please refer to the attached Figure 6 As shown, on the basis of Example 1, the upper end of the first assembly wall 1 and the inside of the second assembly wall 2 are composed of an inner wall 18, an insulation layer 19, an inner reinforcement layer 20 and an outer wall 21, and the insulation The layer 19 is arranged on the left side of the inner wall 18 , and the inner reinforcement layer 20 is arranged between the outer wall 21 and the insulation layer 19 .

[0038] The thermal insulation layer 19 can play the role of thermal insulation for the upper end of the first assembly wall 1 and the second assembly wall 2, and improves the use effect of the device. The inner reinforcement layer 20 can further improve the strength of the upper end of the first assembled wall body 1 and the second assembled wall body 2 to ensure safety.

Embodiment 3

[0040] Please refer to the attached Figure 6 As shown, on the basis of Embodiments 1 and 2, the upper end of the first assembly wall 1 and the inside of the second assembly wall 2 are also provided with reflective grooves 22, and the reflective grooves 22 are arranged between the inner reinforcement layer 20 and the insulation layer 19 between.

[0041] When the indoor heat radiates through the second assembly wall 2, the heat will be reflected in the reflective groove 22, thereby achieving the purpose of heat preservation and improving the effect of heat preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com