Tent pan head structure with connecting pieces of variable included angles

A technology of connecting parts and included angles, applied in tents/canopies, building types, buildings, etc., can solve the problems of low assembly efficiency, high mold cost, lack of flexibility and versatility, etc., to reduce fixed costs and reduce parts. Quantity, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

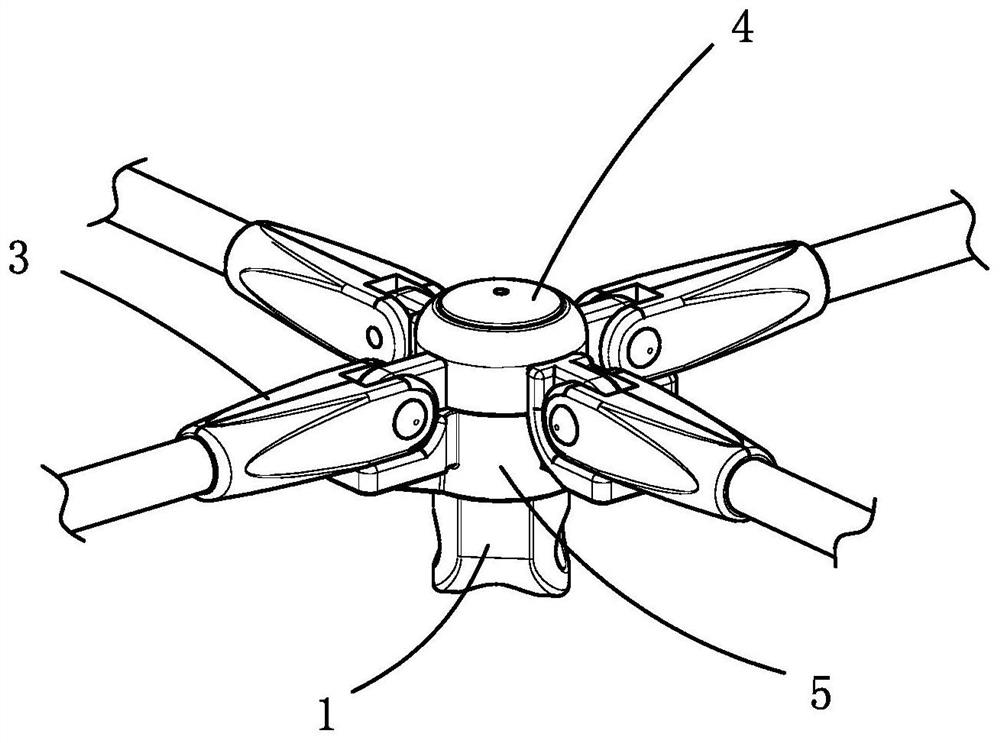

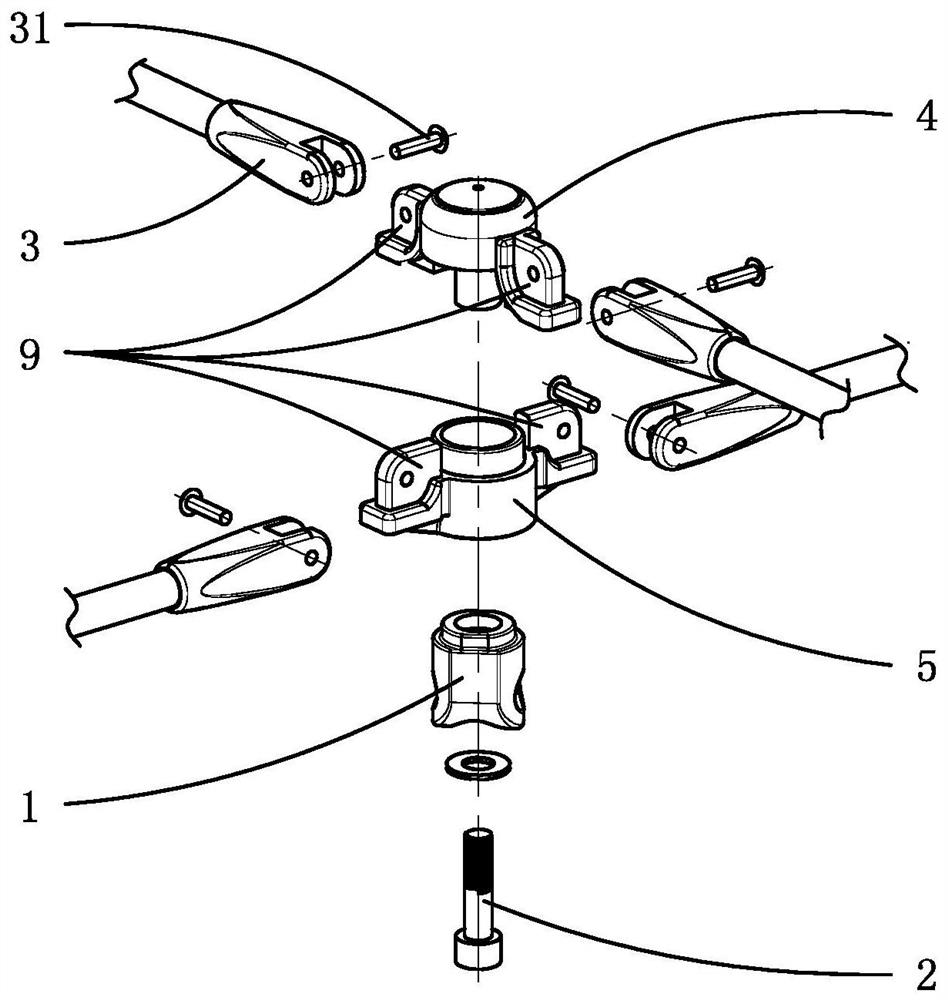

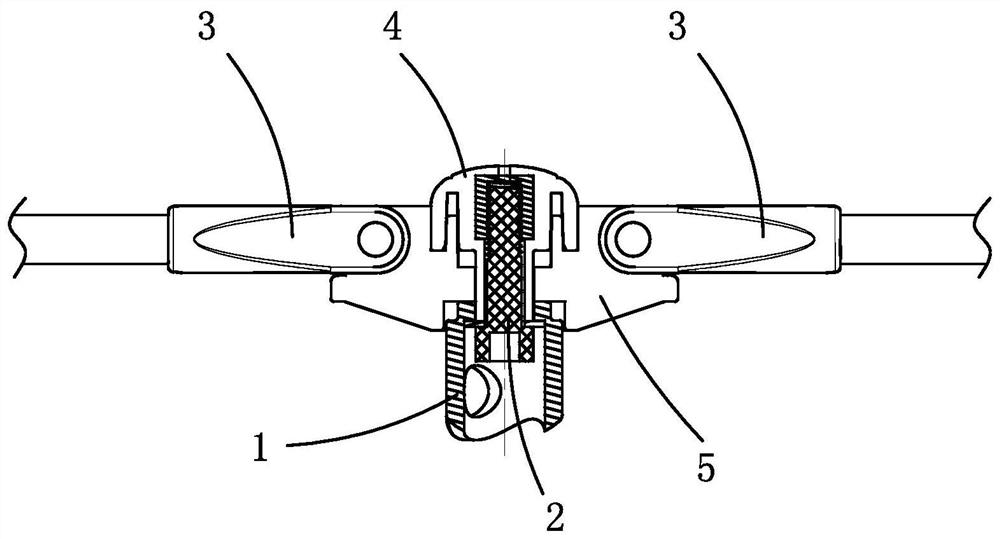

[0033] Such as figure 1 , figure 2 The shown embodiment 1 is a tent pan head structure with a variable angle between the connecting parts, mainly including axial pins 1 coaxially arranged, pan head bolts 2, support rods 3, upper hangers 4 and lower hangers 5, etc. Component. Among them, the upper hanger 4 is at the top, and the lower one is the lower hanger 5 and the axial pin 1 in turn. The pan head bolt 2 is used to lock the upper hanger 4, the lower hanger 5 and the axial pin 1 in the axial direction. 4 and the outer side wall of the lower hanging part 5 are fixed with a connector 9, and the inner end of the support rod 9 is connected with the connector 9 by a support rod pin 31.

[0034] Such as Figure 5 , Figure 6 As shown, on the outer wall of the upper hanging part 4, two connecting parts 9 are arranged symmetrically on the peripheral surface of the outer wall. The lower end surface of the upper hanger 4 is provided with a concave upper hanger socket groove 41 i...

Embodiment 2

[0041] Such as Figure 10 , Figure 11 The shown embodiment 2 is another tent pan head structure with variable angles between the connecting parts. The biggest difference between Embodiment 2 and Embodiment 1 is that a support rod torsion spring 32 is installed between the connecting piece 9 and the connecting rod 3 . Such as Figure 12 , Figure 13 As shown, the connector pin hole 92 on the connector 9 fixed on the outer wall of the upper hanger 4 and the lower hanger 5 is a through hole that is adapted to the torsion spring 32 of the support rod, and one end of the torsion spring 32 of the support rod is hooked on the end of the connection rod 3. end, and the other end is hooked in the connector pin hole 92.

[0042] The assembly steps of the tent pan head structure in this example can be found in Figure 14 to Figure 17 :

[0043] Figure 14 As shown, prepare the lower pendant 5, a pair of support rod torsion springs 32, a pair of support rod pins 31, and a pair of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com