Grouting stopping method for stratum pre-grouting reinforcement

A technology of grouting reinforcement and pre-grouting, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., to achieve the effect of promoting effect, simple operation, and reliable grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

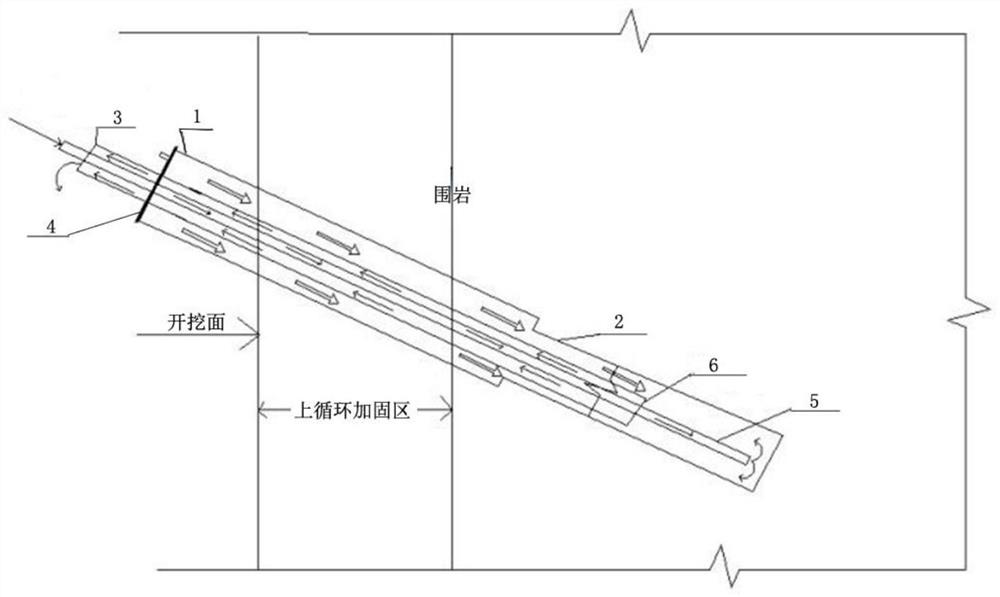

[0014] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0015] This embodiment provides a grout-stopping method for pre-grouting reinforcement in the formation, which includes the following steps:

[0016] S1. Install the orifice pipe 1 on the surface of the formation to be reinforced by grouting, and drill the grouting hole 2 along the orifice pipe 1 to the design depth; insert the PVC material grouting pipe into the grouting hole according to the design depth, and The iron grouting pipe on the flange cover plate of the orifice pipe is connected, and the flange cover plate 4 covers the front end of the orifice pipe 1 and is fixed and sealed with bolts.

[0017] S2. Extend the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com