Negative pressure sensing type automatic temperature control opening and closing fireproof smoke exhaust valve

A technology of automatic temperature control and smoke exhaust valve, applied in the direction of temperature control, non-electric variable control, valve lift, etc., can solve the problems of poor stability, low reusability, and electronic drive is susceptible to high temperature interference, and achieves high stability. , No need for repeated use, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

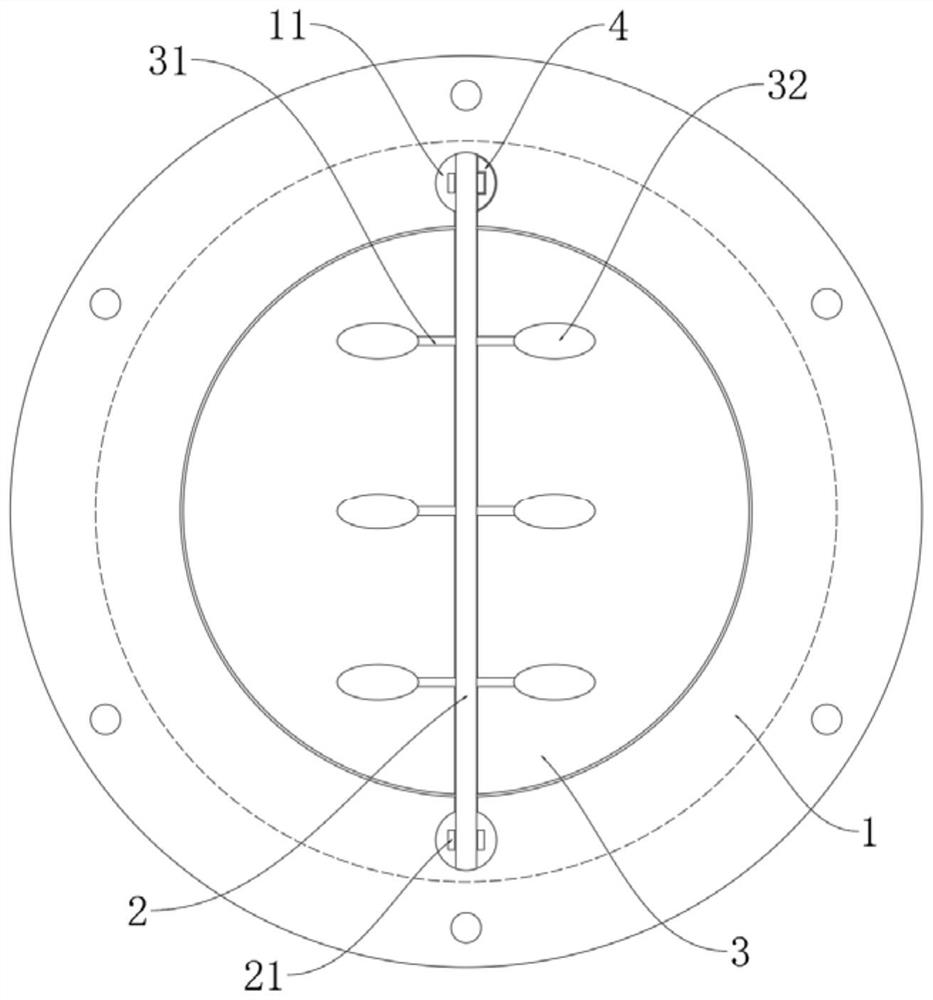

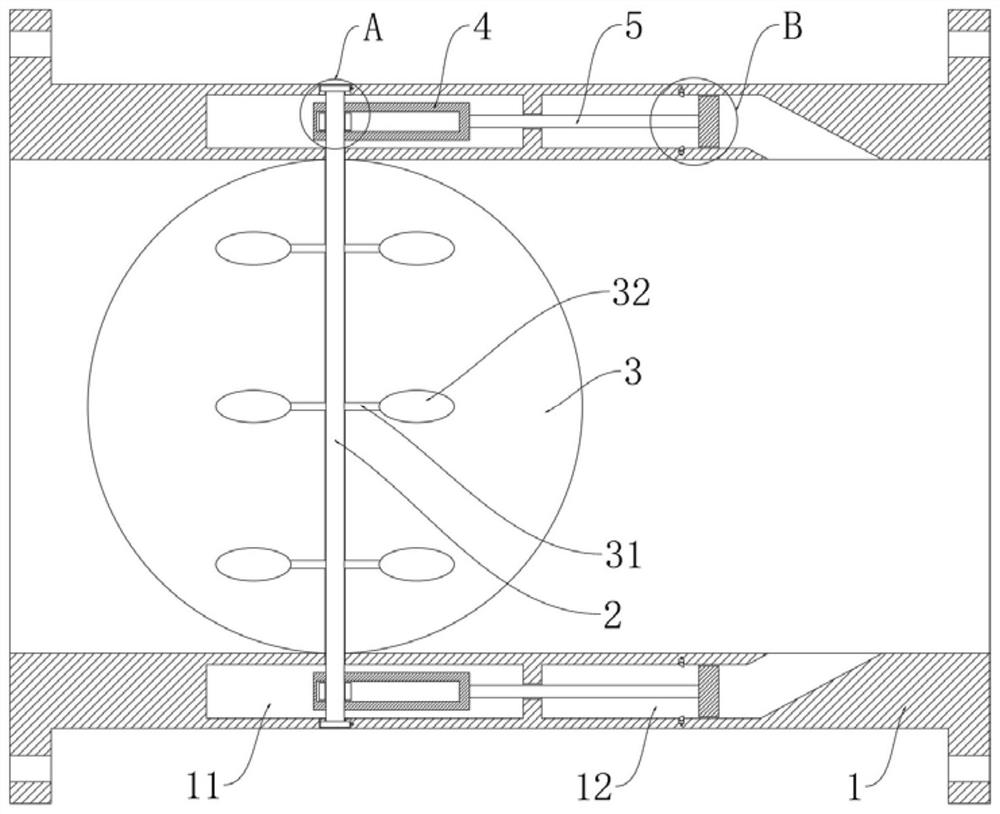

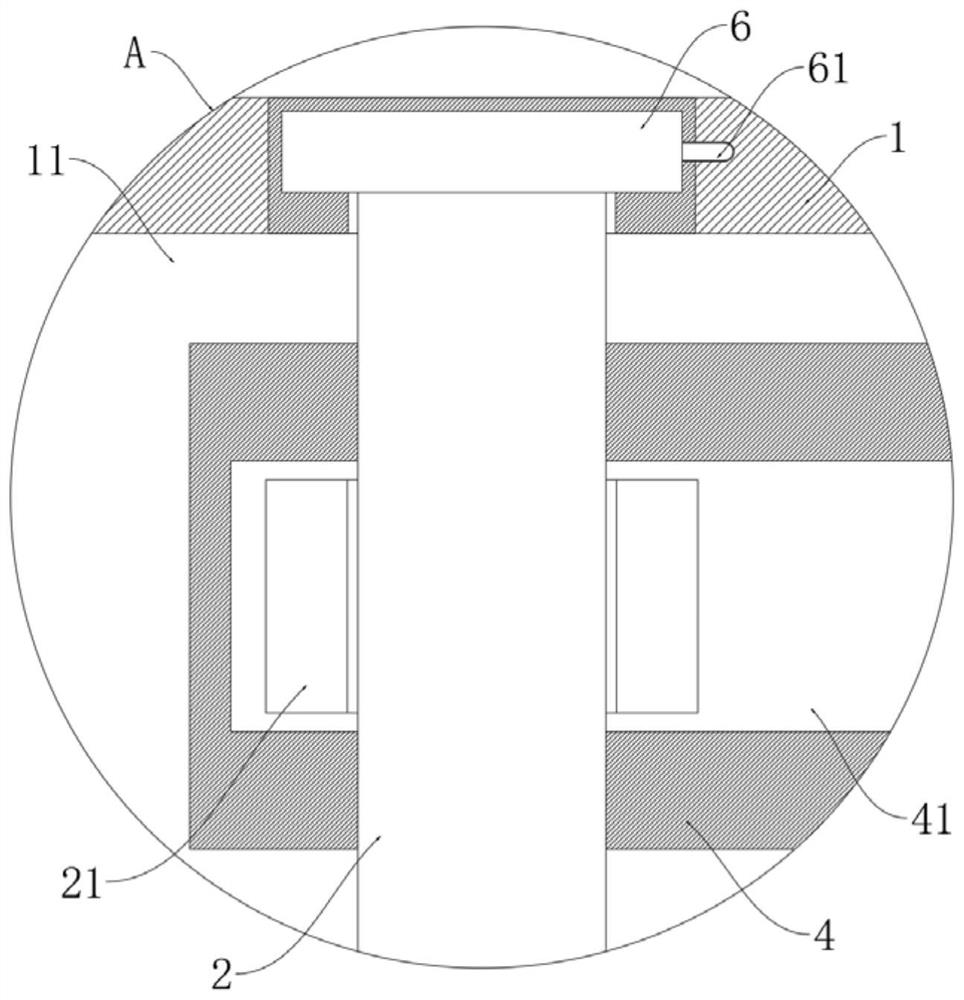

[0022] Refer Figure 1-5 A negative pressure perceptual automatic temperature control opening and closing fire exhaust valve, including the valve cartridge 1, and the inner wall of the valve cartridge 1 opens two drive chambers 11, the inner wall of the valve cartridge 1 is rotated with a control tube axis. 2, each drive chamber 11 is mounted on one side wall of the inner wall of the valve cartridge 1, and the two ends of the control tube shaft 2 extend to the two drive chamber 11 and rotate in two hollow. In the shaft sleeve 6, the control tube shaft 2 is mounted with two driving gear 21 in the two drive chamber 11, and each drive chamber 11 is slidably mounted, and the groove colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com