Method for measuring repeated installation error of inertial navigation equipment

A technology of installation error and measurement method, applied in measurement devices, mechanical measurement devices, angle/taper measurement, etc., can solve the problem of difficulty in exerting the precision of inertial navigation equipment, and achieve good engineering application prospects, high precision, and wide practical range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

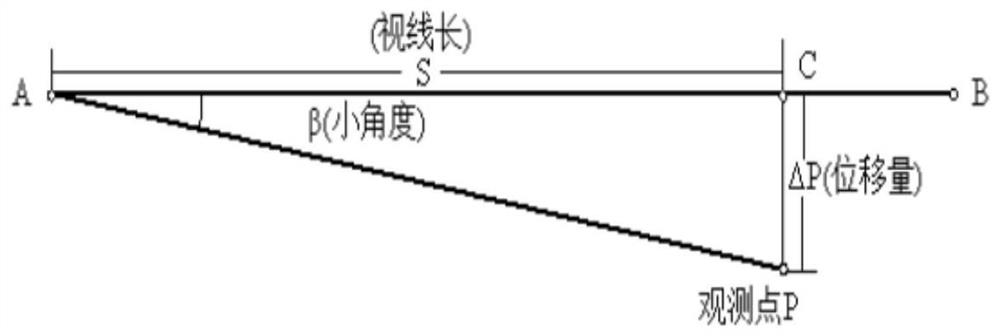

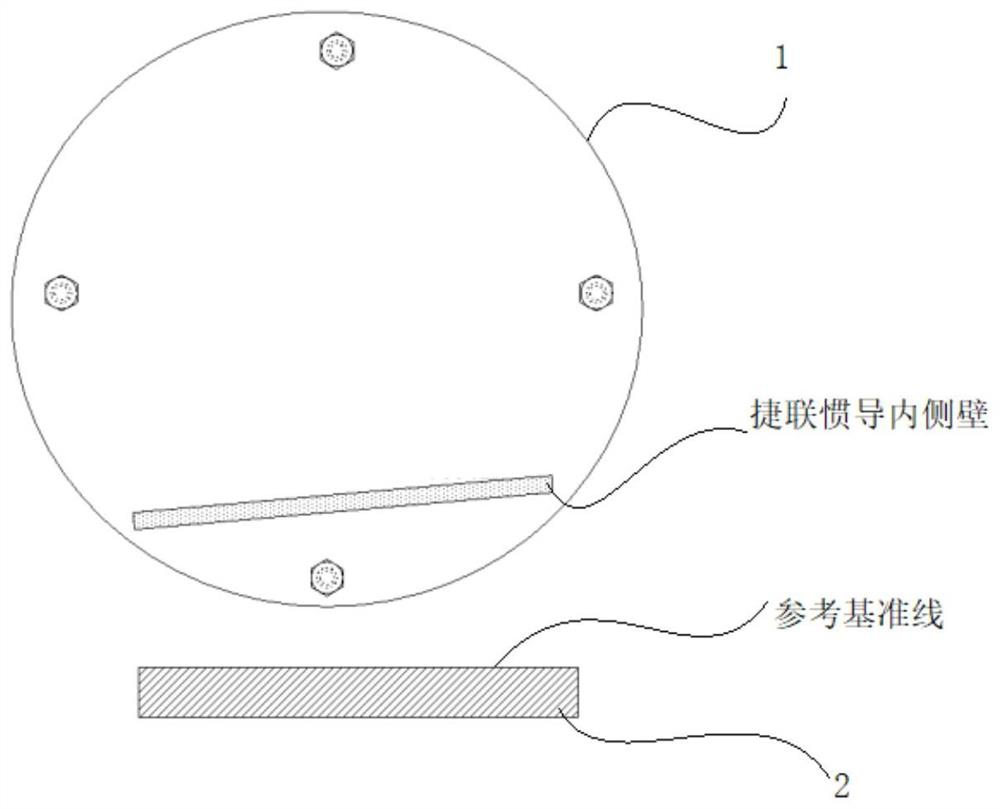

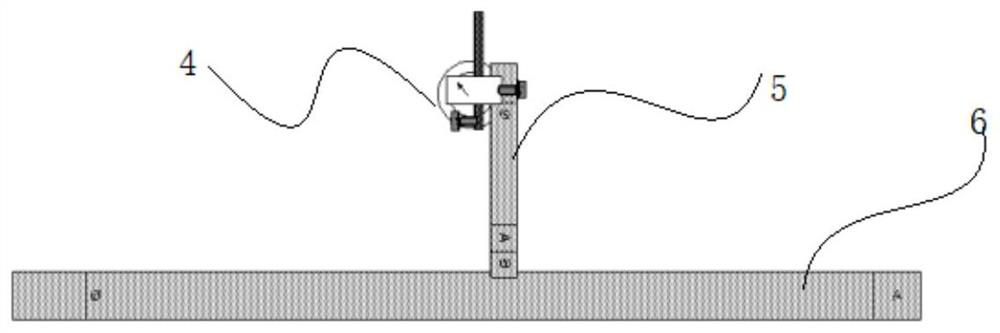

[0031] Embodiment 1, taking a kind of marine inertial navigation equipment as an example, when considering repeated installation, the horizontal accuracy of repeated installation can be ensured by the precision machining surface of the inertial navigation equipment installation base and the equipment base, and repeated installation needs to measure the inertial navigation equipment installation. For the variation of the front and rear course angles, the present invention calculates the variation of the course angle according to the principle of the small angle method, and successfully solves the problem of repeated installation of the inertial navigation equipment. details as follows:

[0032] 1. Principle of small angle method

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap