Method and apparatus for transfer of two-dimensional materials

A technique for removing samples, applied in devices, chemical instruments and methods, coatings, etc. for applying liquids to surfaces, which can solve problems such as damage to materials, loss of quality, damage to materials of interest, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following detailed description is exemplary in nature and is not intended to limit the scope, applicability, or configuration of the invention in any way. Rather, the following description provides some practical illustrations for implementing various embodiments of the invention. Examples of construction, materials, dimensions, and manufacturing processes are provided for selected elements, and all other elements employ constructions, materials, dimensions, and manufacturing processes known to those of ordinary skill in the field of the invention. Unless otherwise indicated, the drawings are not necessarily drawn to scale. Those skilled in the art will recognize that there are a wide variety of suitable alternatives to many of the recorded examples.

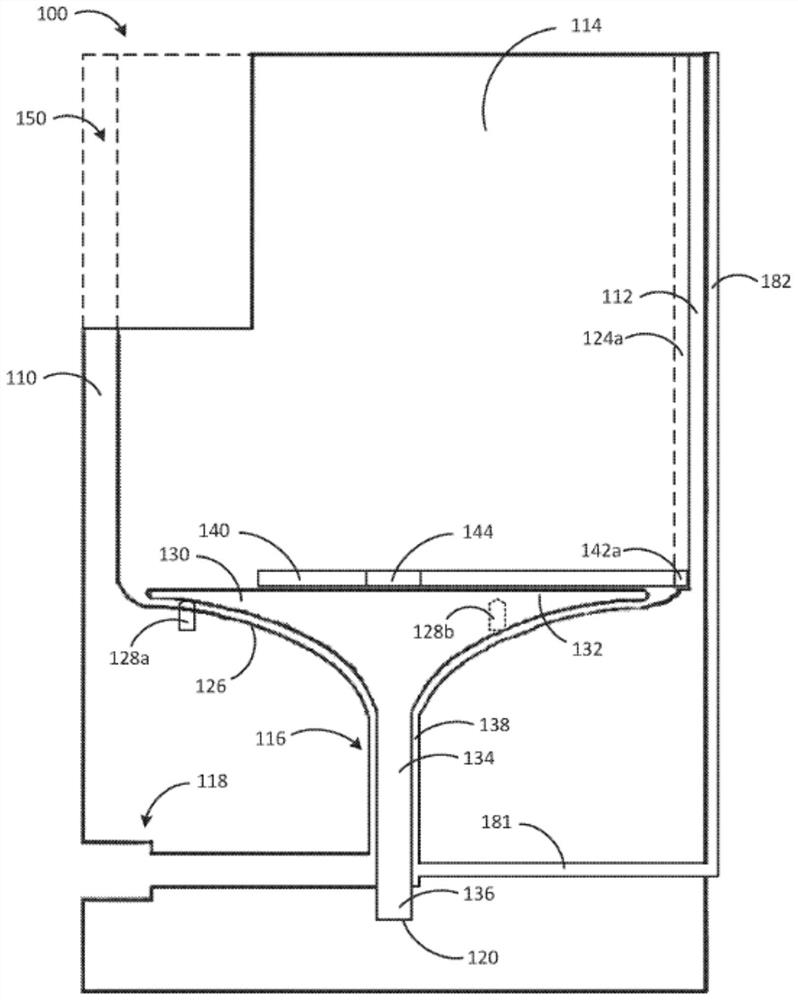

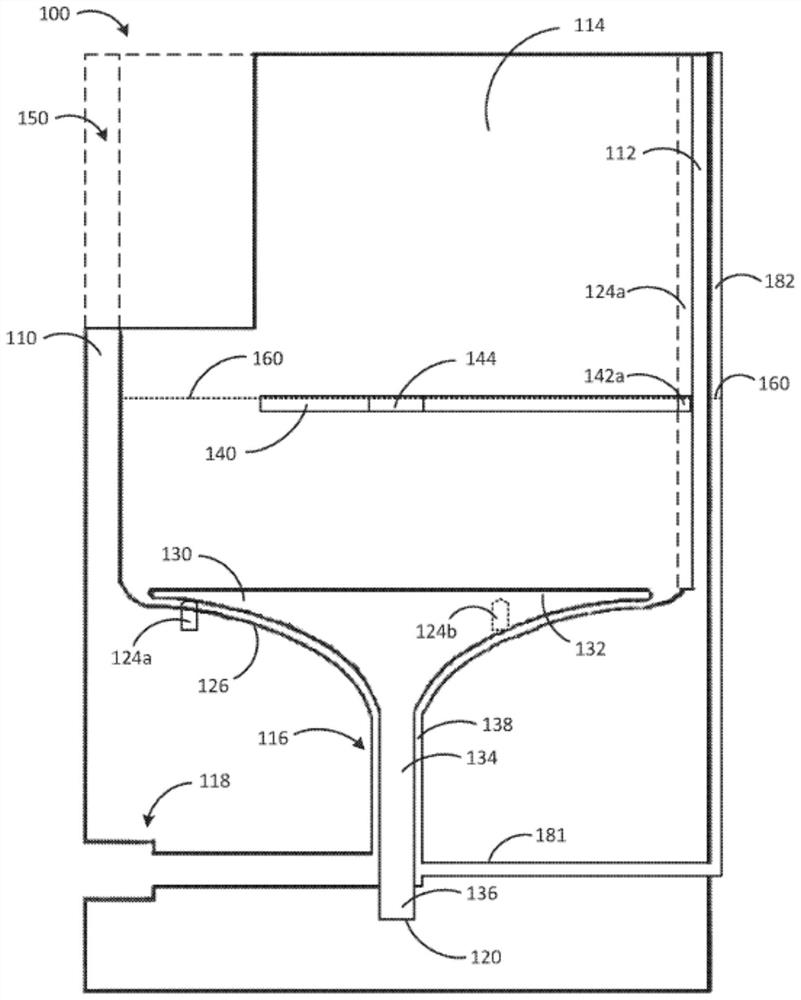

[0040] Figure 1A A cross-sectional side view of an exemplary processing vessel in a transfer system is shown. The processing vessel 100 includes a main chamber 110 having a sidewall 112 defining a cavity 114 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com