Gate discharging type quantitative bin for sow precision feeding

A quantitative warehouse and precision technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve problems such as motor damage, error between weighing and actual output, and impact on quantitative accuracy, so as to reduce motor load, The effect of small residual material and improving quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

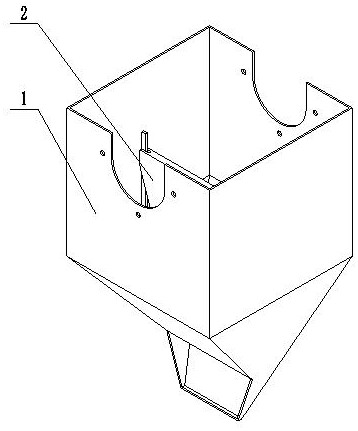

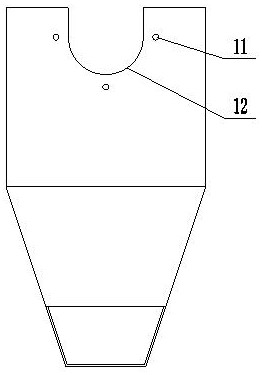

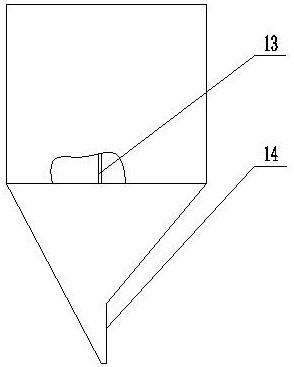

[0016] refer to figure 1 , a gate unloading type sow precision feeding quantitative bin proposed by the present invention, comprising: a quantitative bin body (1), a trapezoidal gate plate (2); the upper part of the quantitative bin body (1) is provided with a connecting hole (11) and the U-shaped groove (12) of the shaft tube of the feeding shaft, in order to fix the position of the shaft tube of the feeding screw shaft; the lower part of the quantitative warehouse body (1) is provided with a relatively long dripping plate (15) and a short The dripping plate (16) is misplaced to form a vertical trapezoidal discharge port (14), and vertical guide strips (12) are symmetrically arranged on both sides inside the quantitative chamber; the top of the trapezoidal gate plate (2) is chamfered, and the upper part A connection hole (21) for a connecting rope is provided, a drip open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com