Disordered heating cigarette processing technology

A processing technology and cigarette technology, which are applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of difficulty in rolling, difficulty in making shreds of disorderly heated cigarettes, poor quality stability of finished cigarettes, etc., and achieve the effect of not easy to stick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

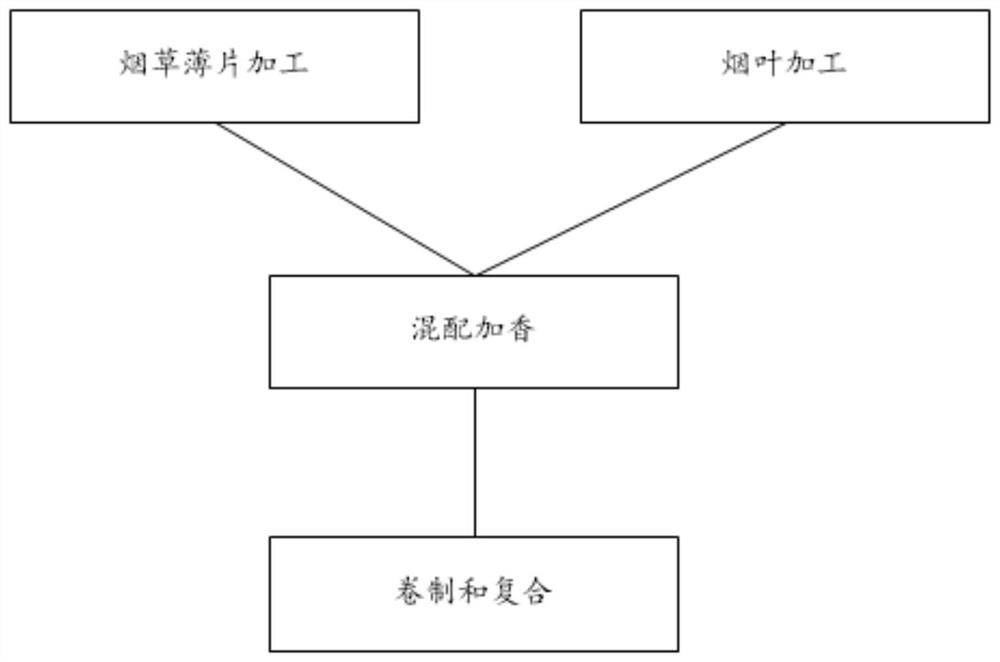

[0019] Embodiments of the present invention: as figure 1 As shown, a disorderly heating cigarette processing technology comprises the following steps:

[0020] Step a, tobacco sheet processing, remove the tobacco sheet with a water content of 6%-8% by weight and put it on the uncoiler after removing the packaging, and complete the uncoiling by the uncoiler. 30%—40%) ± 3%, to prevent the sheet from absorbing moisture;

[0021] Then the unrolled tobacco sheet is sent to the tearing machine, and the tearing machine tears the tobacco sheet into an area of 100mm 2 -150mm 2 Tobacco sheets are square, the ambient temperature is 18°C-22°C, the relative humidity (30%-40%) ± 3% during the tearing process, to prevent the sheet from absorbing moisture, tear the sheet into 100mm 2 -150mm 2 The squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com