Accurate ink supply system

An ink supply and precise technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of pipeline blockage, production efficiency improvement, lack of skilled personnel, etc., and achieve the advantages of light structure and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

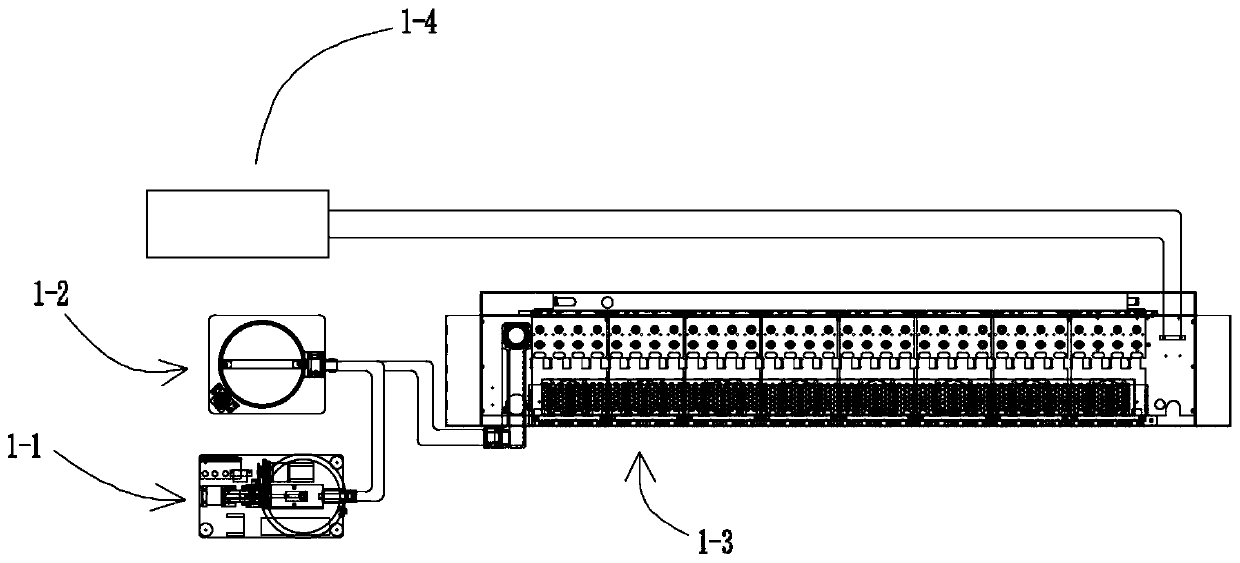

[0066] A precision ink supply system such as figure 1 shown, including the following parts:

[0067] The automatic ink filling system 1-1 is connected to the centralized ink delivery system 1-2 through pipelines, and is used to supply ink to the centralized ink delivery system 1-2;

[0068] The centralized ink supply system 1-2 is connected upstream to the automatic ink supply system 1-1, and downstream to the full digital ink supply system 1-3, which is used to centrally and quantitatively deliver the ink to the full digital ink supply system 1-3;

[0069] The full digital ink supply system 1-3, the upstream is connected with the centralized ink supply system 1-2 through the pipeline, which is used to supply the ink to the printing machine evenly and stably;

[0070] The control system 1-4 is electrically connected with the automatic ink supply system 1-1, the centralized ink supply system 1-2 and the full digital ink supply system 1-3, and is used to control the smooth oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com