A preparation method of small-sized high-precision molybdenum alloy parts

A molybdenum alloy, high-precision technology, applied in the field of powder metallurgy, can solve the problems of delayed molybdenum alloy sintering and densification process, uneven distribution of granulated powder elements, unfavorable product comprehensive performance, etc., to achieve uniform and stable slurry supply, high quality Effect of dimensional accuracy and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

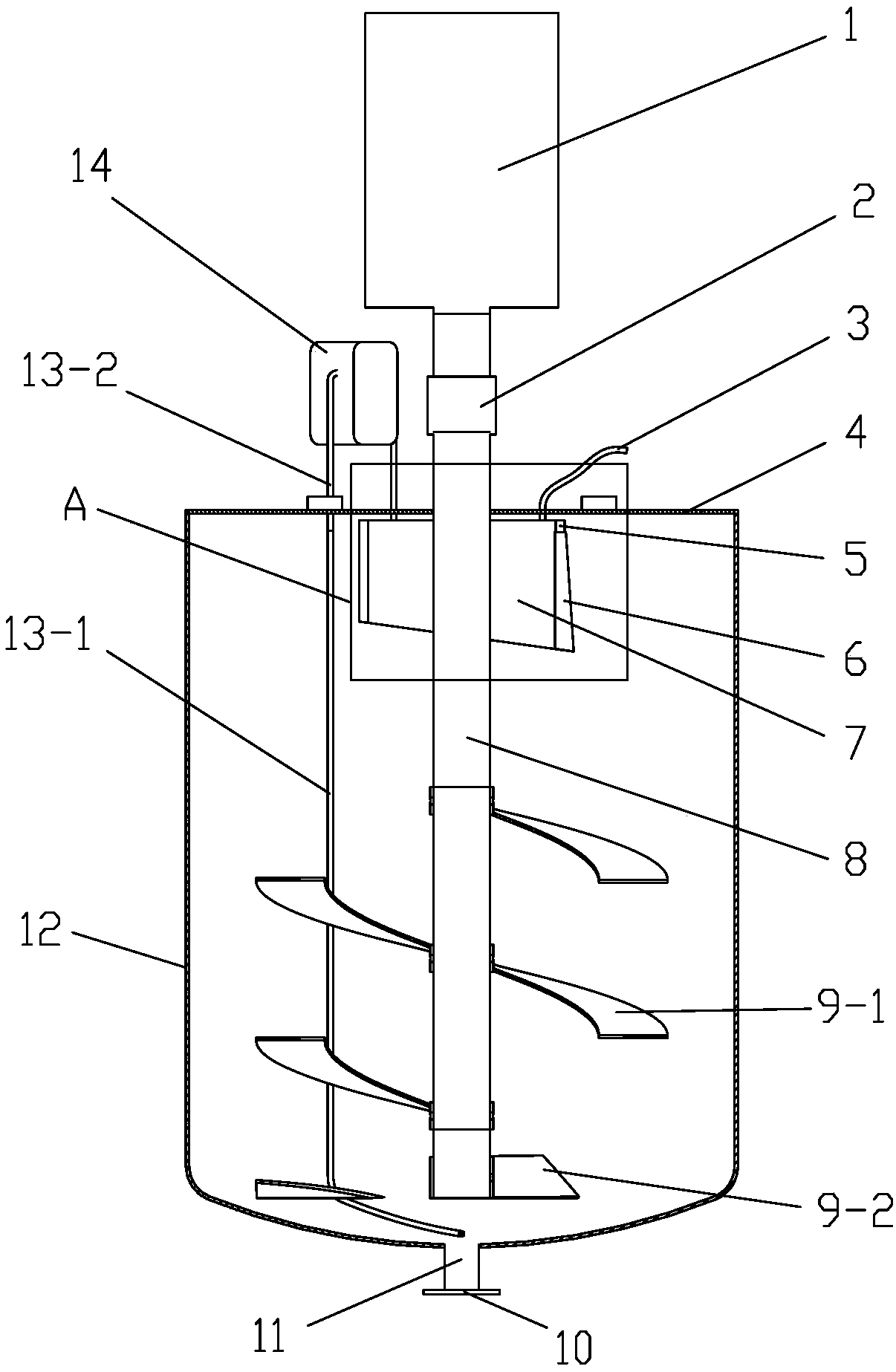

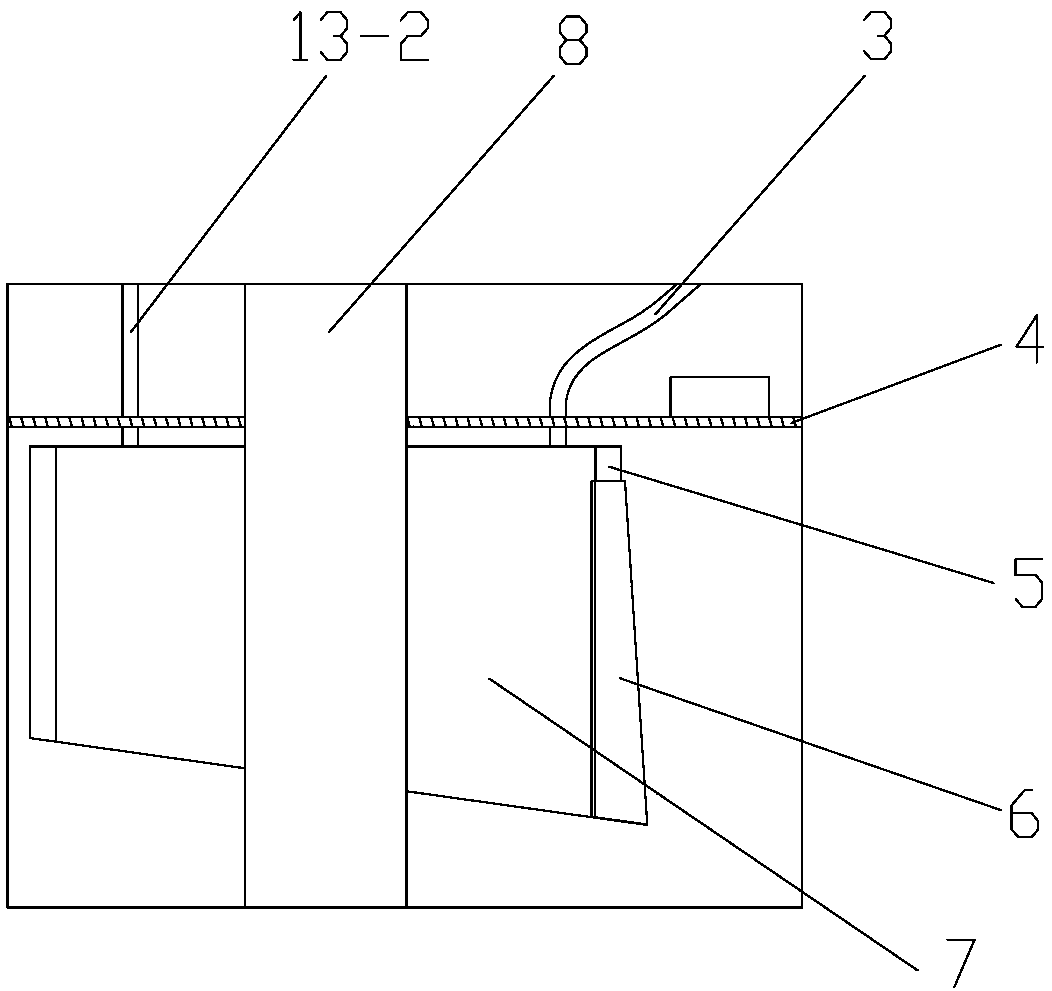

[0045] The equipment used in the preparation process of the small-sized high-precision molybdenum alloy parts of the present invention includes a circulating slurry tank. like figure 1 and figure 2 A circulating slurry tank shown includes a tank body 12 and a tank cover 4 with a movable cover arranged on the tank body 12, the bottom of the tank body 12 is provided with a discharge port 11, and the discharge port 11 is provided with There is a valve 10, the inside of the tank body 12 is provided with a stirring shaft 8, the lower part of the stirring shaft 8 is provided with a blade, and the upper part of the stirring shaft 8 passes through the tank cover 4 and is connected with a drive mechanism located outside the tank body 12, Described tank body 12 is provided with feeding pipe, as figure 1 As shown, the feed pipe includes a steel pipe 13-1 and a rubber hose 13-2 connected to the steel pipe 13-1, the steel pipe 13-1 is a stainless steel pipe, the steel pipe 13-1 is locat...

Embodiment 1

[0056] The preparation method of the small-sized high-precision molybdenum alloy part of this embodiment comprises the following steps:

[0057] Step 1, using 20g La with a mass purity of more than 99.95% 2 o 3 powder and 10g CeO 2 The powder is additive powder. Put 970g of molybdenum powder and additive powder together into a ball mill jar, then add 4000g of molybdenum balls and 15mL of absolute ethanol, and then install it on a ball mill for ball milling under argon atmosphere. The speed of ball milling is 280r / min, the time of ball milling is 60h, so that molybdenum powder, La 2 o 3 , CeO 2 Repeat the process of powder deformation, cold welding, crushing, etc. to obtain a molybdenum alloy composite powder that is cold welded between elements and evenly distributed. Dissolve 50g of PVA in 1000mL of deionized water, add 15g of PAA to mix and prepare a solution, and add the solution to the circulating slurry material tank, then add molybdenum alloy composite powder into ...

Embodiment 2

[0065] The preparation method of the small-sized high-precision molybdenum alloy part of this embodiment comprises the following steps:

[0066] Step 1, using 15g La with a mass purity of more than 99.95% 2 o 3 powder and 0.3g CeO 2 The powder is additive powder, put 984.7g molybdenum powder and additive powder together into a ball mill jar, then add 5987g molybdenum balls and 15mL absolute ethanol, then install it on a ball mill, and ball mill under vacuum condition, the speed of ball milling is 400r / min , the ball milling time is 24h, so that molybdenum powder, La 2 o 3 , CeO 2 Repeat the process of powder deformation, cold welding, crushing and so on to obtain molybdenum alloy composite powder which is cold welded and evenly distributed between elements. Dissolve 10g PVA in 700mL deionized water, add 10g PAA to mix and prepare a solution, and add the solution to the circulating slurry material tank, then add molybdenum alloy composite powder into the solution and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com