Light ceramic produt and manufacturing method thereof

A lightweight ceramic and manufacturing method technology, applied in the direction of ceramic products, clay products, and other household appliances, can solve the problems of ceramic hollow body damage, difficulty in providing uniform and stable products, and difficulty in dispersing, so as to improve fluidity, The effect of uniform and stable supply and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Manufacturing example of lightweight ceramic products of the present invention (manufacturing example of extrusion processing)

[0039] First, prepare Esfearz SL150 [gross specific gravity 0.25-0.42, compressive strength (40% presence) 700kgf / cm] manufactured by E company in Australia 2 , Melting point 1600°C, powder diameter 20-150μm] The ceramic hollow body used as the core material was classified, and only the powder with a powder diameter of about 150μm was taken out and used. The appearance of the ceramic hollow body is white powder, and its chemical composition is SiO 2 59.7%, Al 2 o 3 38.3%, Fe 2 o 3 0.40%, CaO 0.20%, TiO 2 1.09%, loss on ignition is 0.30%.

[0040] Then, water was added to 54.9% of silicic acid, 12.6% of sodium oxide, 5.7% of calcium oxide, 8.4% of potassium oxide, 15.8% of aluminum oxide, and 3% of aluminum borate as a coating agent for forming an inorganic coating layer, and the viscosity was measured. Adjustment. In ...

Embodiment 2

[0058] Embodiment 2: the manufacturing example of extrusion molding of light weight ceramic product of the present invention

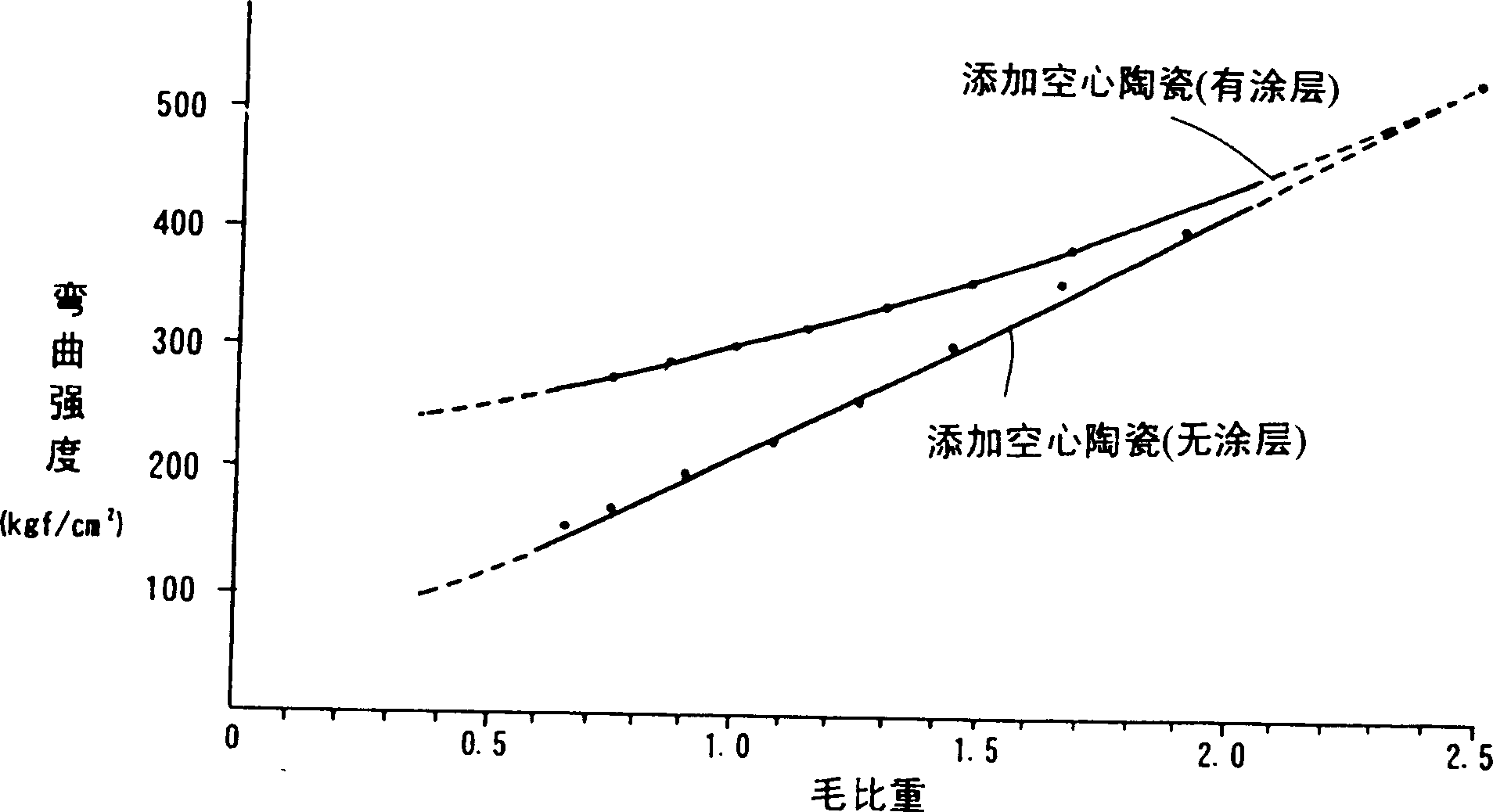

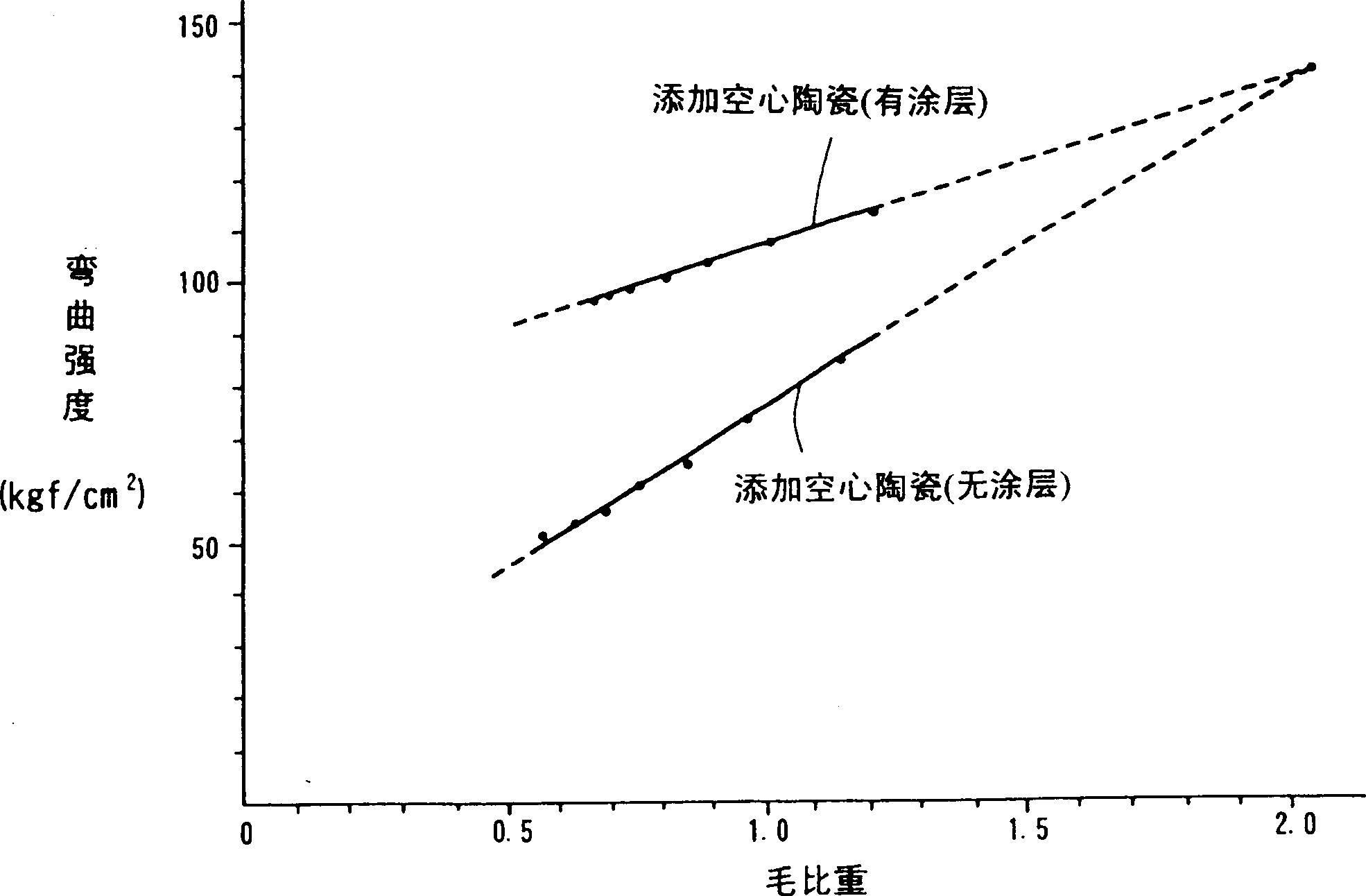

[0059] The hollow ceramic powder of the double-layer structure obtained by Example 1 is mixed with the modeling clay of plastic clay according to the compounding ratio recorded on Table 3, then 25 parts by weight of water is added thereto and mixed, and extruded by a vacuum and mud machine, Ten molded bodies of the same size as in Example 1 were produced. The chemical composition of the modeling clay used at this time is SiO 2 48.6%, Al 2 o 3 34.1%, Fe 2 o 3 1.1%, CaO 0.4%, TiO 2 0.6%, MgO 0.2%, K 2 O 0.7%, Na 2 O 0.2%.

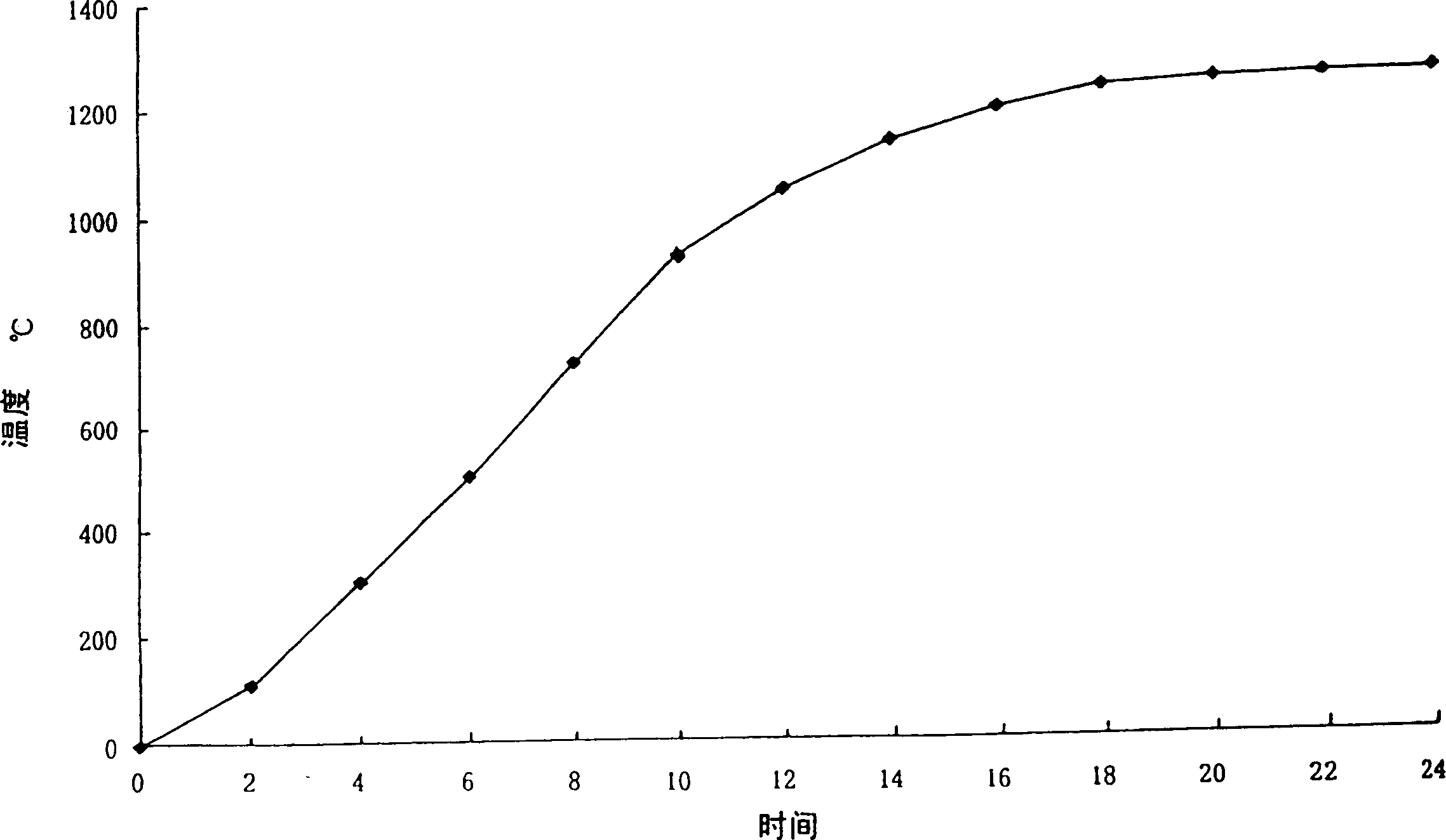

[0060] Thereafter, the obtained molded product was dried in a drying room at about 40° C. for 10 hours and at 60° C. for 24 hours, and oxidized and fired at 1280° C. in an electric furnace as in Example 1.

[0061] On the other hand, as a control, a product without adding hollow ceramic powder was also produced.

[0062] G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com