A method for improving the coercive force of an arc-shaped NdFeB magnet

A technology of NdFeB and coercive force, which is applied in the field of coercive force improvement of arc-shaped NdFeB magnets, can solve the problems of low applicability, low utilization rate of heavy rare earth, simple operation and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation of the heavy rare earth coating is to prepare a heavy rare earth slurry by mixing heavy rare earth elements with organic binders and organic solvents, and use screen printing to screen a layer of heavy rare earth slurry on the surface of the flexible film and dry it to form a heavy rare earth coating. Rare earth coating.

[0034] The heavy rare earth element is any one of pure metal, alloy or compound powder, and the heavy rare earth element is dysprosium or terbium, wherein the selected pure metal, alloy or compound powder has a particle size of 1-200 μm. The organic adhesive is a resin adhesive or a rubber adhesive, and the organic solvent is a ketone, benzene or ester thinner.

[0035] The weight ratio of the heavy rare earth element in the heavy rare earth coating on the surface of the flexible film to the weight of the curved NdFeB magnet 1 to be coated is 0.1%-1.5%.

[0036] After the above material selection is completed, proceed as follows.

[...

Embodiment 1

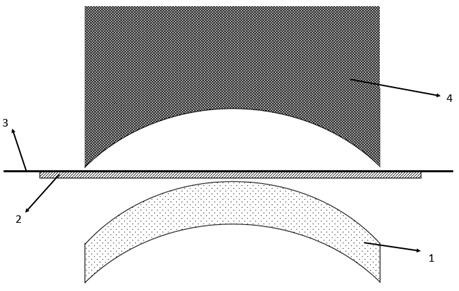

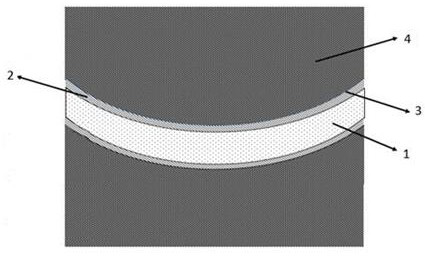

[0046] see figure 1 , figure 2 , a coercivity enhancing method for an arc-shaped NdFeB magnet, comprising the following steps:

[0047] like figure 1 As shown, the arc-shaped NdFeB magnet with a thickness of 1 mm is placed vertically with the convex surface upward, and the pure Dy powder with an average particle size of 1 μm is mixed with a resin-based adhesive and a benzene-based thinner to form a heavy rare earth slurry. Use screen printing technology to screen-print a layer of heavy rare earth film on a flexible plastic film with a thickness of 0.05mm, and ensure that the shape and surface area of the heavy rare earth film are consistent with the convex surface of the arc-shaped magnet by controlling the pattern and mesh of the screen. The shape and surface area are consistent, and the weight ratio of heavy rare earth to the arc magnet to be coated is 0.1%.

[0048] Transfer the flexible film 3 coated with the heavy rare earth coating 2 directly above the convex surfa...

Embodiment 2

[0055] In this embodiment, a heavy rare earth coating is formed on an arc-shaped NdFeB magnet with a thickness of 15 mm. Pure Tb powder with an average particle size of 100 μm is mixed with a rubber-type adhesive and a ketone thinner to form a heavy rare earth slurry. Screen printing technology screen-prints a layer of heavy rare earth film on a flexible plastic film with a thickness of 0.2 mm. The weight ratio of heavy rare earth to the weight of the arc-shaped magnet to be coated is 1.5%. Stage diffusion at 850°C for 72h, aging treatment at 550°C for 15h, and the rest are similar to Example 1.

[0056] After the diffusion is completed, test the magnetic properties of the arc-shaped magnet, and take the magnetic properties of the arc-shaped magnet before diffusion as Comparative Example 2, fill in the above test results in Table 2, and compare and confirm the diffusion effect of the arc-shaped magnet after diffusion.

[0057] Table 2

[0058] Br (KGs) Hcj (KOe)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com