Wood surface painting device for furniture processing

A wood surface and painting technology, which is applied to the device for coating liquid on the surface, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems of low work efficiency, poor work quality, uneven painting, etc. , to achieve the effect of improving work quality, avoiding solidification and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

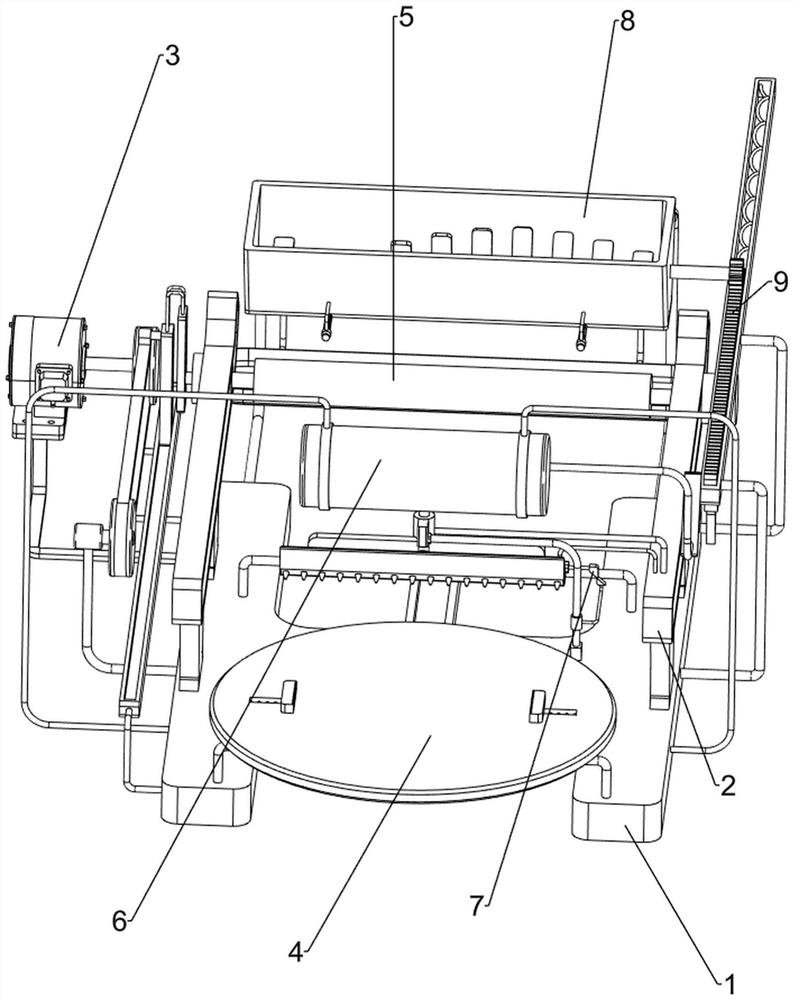

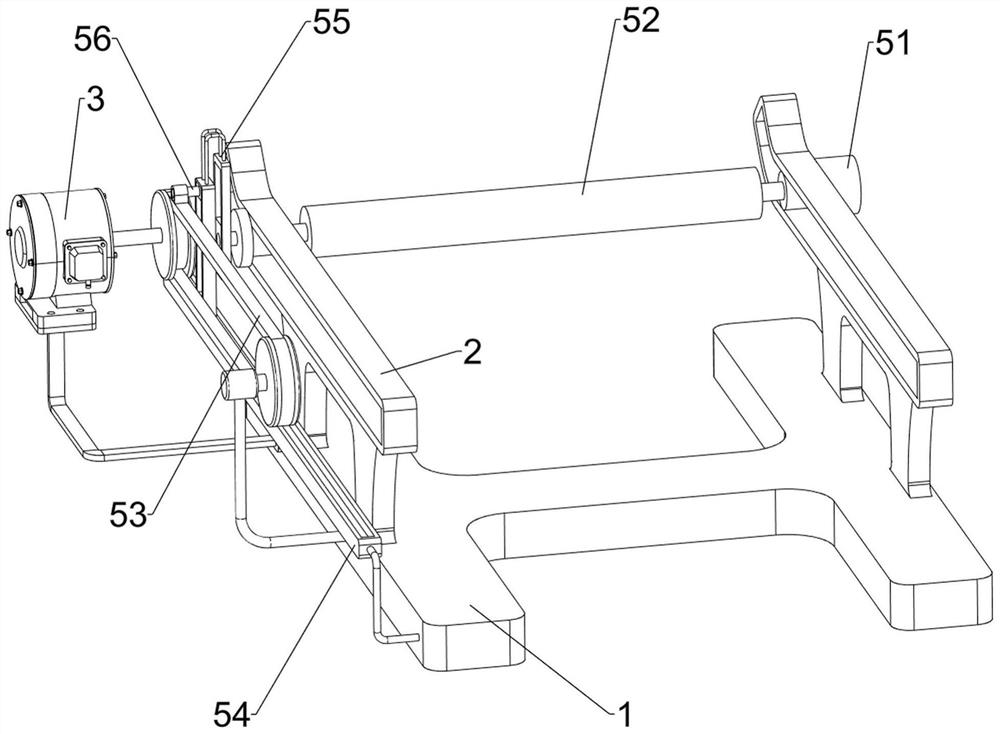

[0024] A wood surface painting device for furniture processing, such as Figure 1-7 As shown, it includes a base plate 1, a first guide sleeve 2, a motor 3, a push clamping mechanism 4 and a painting mechanism 5, the left and right parts of the base plate 1 are provided with the first guide sleeve 2, and the left rear part of the base plate 1 is passed through a bolt A motor 3 is fixedly connected, and the bottom plate 1 is provided with a pushing and clamping mechanism 4 for pushing and clamping by sliding, and the bottom plate 1 is provided with a painting mechanism 5 for painting by sliding.

[0025] When using the device, the staff puts the wood that needs to be painted on the push clamping mechanism 4. After putting it in place, the staff pushes the push clamping mechanism 4 backwards, and then starts the motor 3 to rotate, and the motor 3 rotates to drive The painting mechanism 5 slides forward in the first guide sleeve 2 to paint the wood pushed on the clamping mechanis...

Embodiment 2

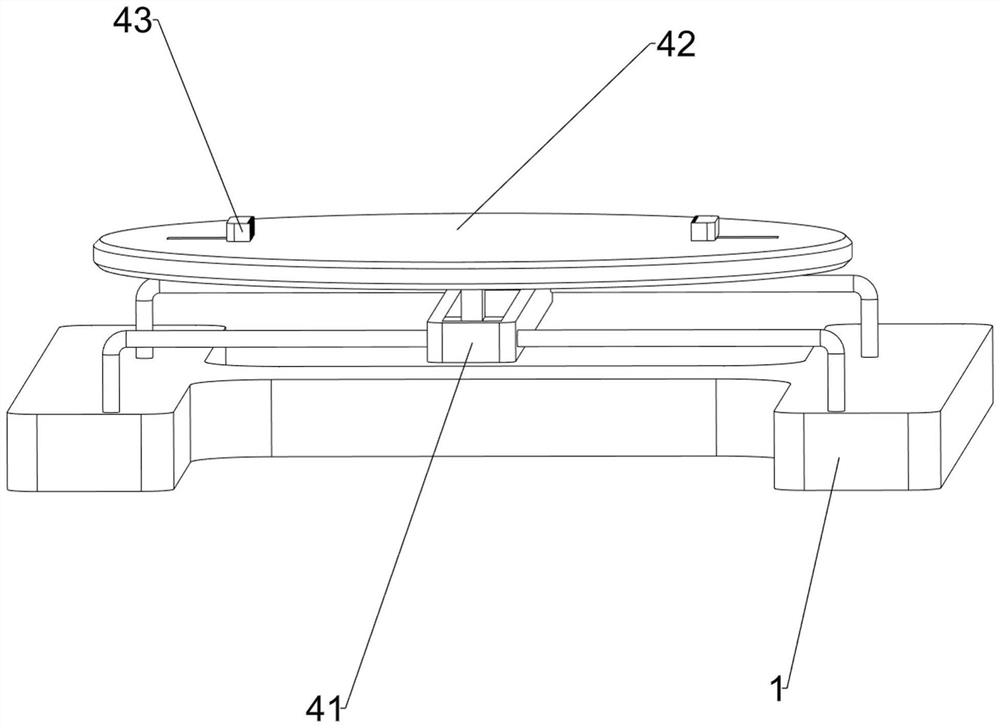

[0031] On the basis of Example 1, such as figure 1 Figure 4 and Figure 5 As shown, it also includes a dust removal mechanism 6, and the dust removal mechanism 6 includes a water tank 61, a shower nozzle 62, a valve 63 and a push switch 64. A valve 63 is provided, and a push switch 64 is provided on the right side of the valve 63, and the push switch 64 cooperates with the supporting plate 42.

[0032] When painting wood, when the pallet 42 moves backward to contact with the push switch 64, the pallet 42 pushes the push switch 64 to move upwards to open the valve 63, and the water in the water tank 61 is sprayed to the pallet through the nozzle 62. On the wood on the board 42, when the supporting board 42 is separated from the push switch 64, the staff pulls the push switch 64 to move downward and reset and close the valve 63, so that the dust on the wood surface can be cleaned up, and the work quality of people is improved. .

[0033] Such as figure 1 and Figure 5 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com