A fully automatic plate bending device

A bending device, fully automatic technology, applied in the direction of safety equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to adjust the bending angle, no protective device sheet material, unqualified products, etc., to achieve enhanced practicability , the effect of reducing safety hazards and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

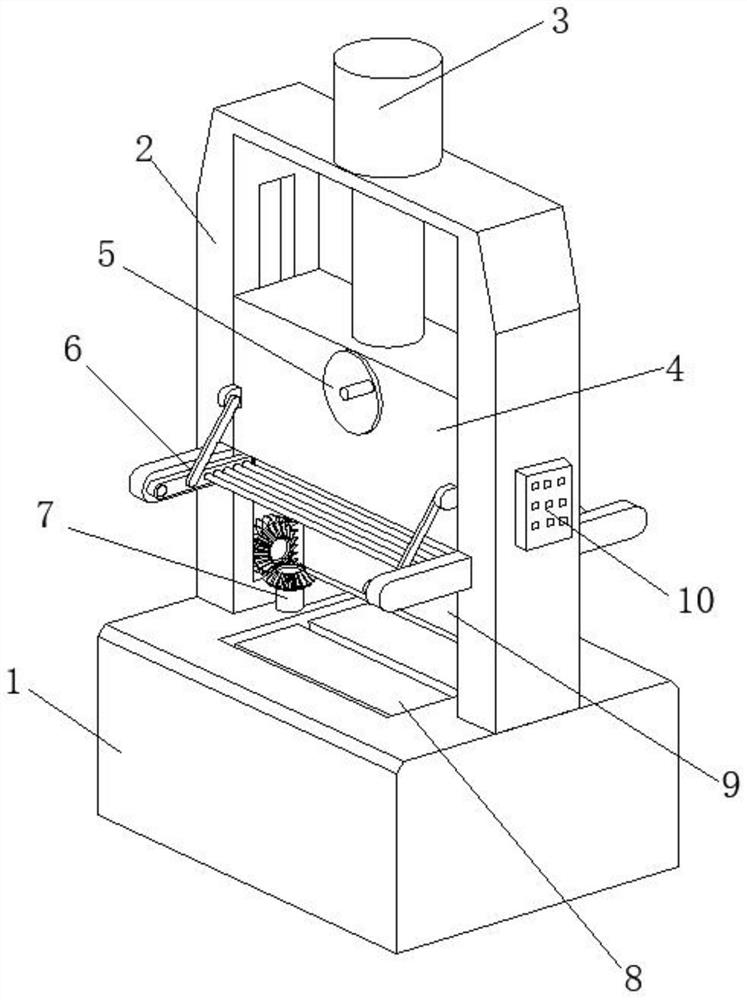

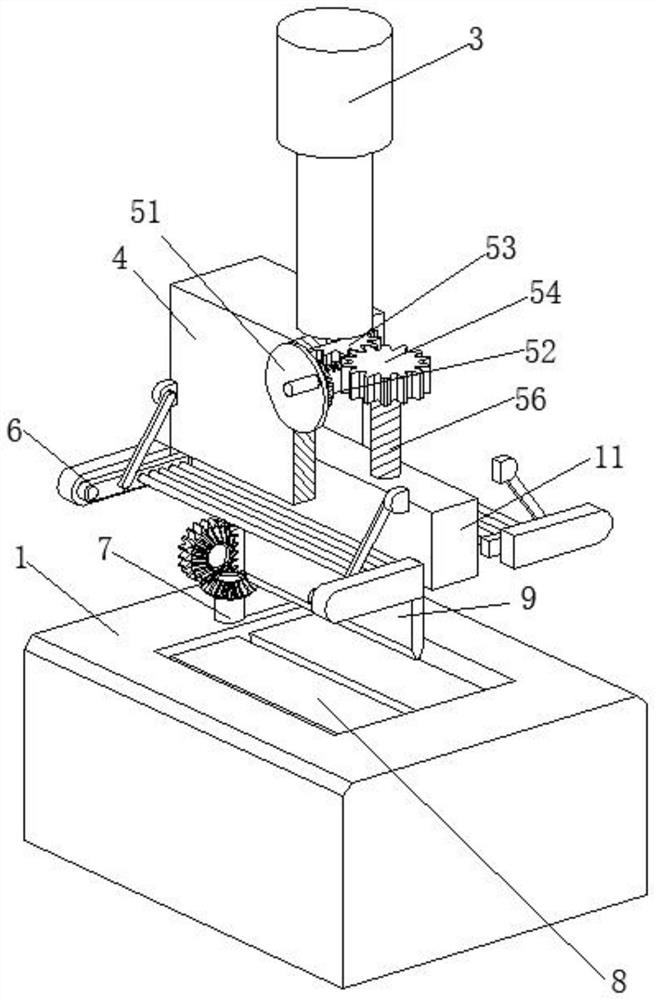

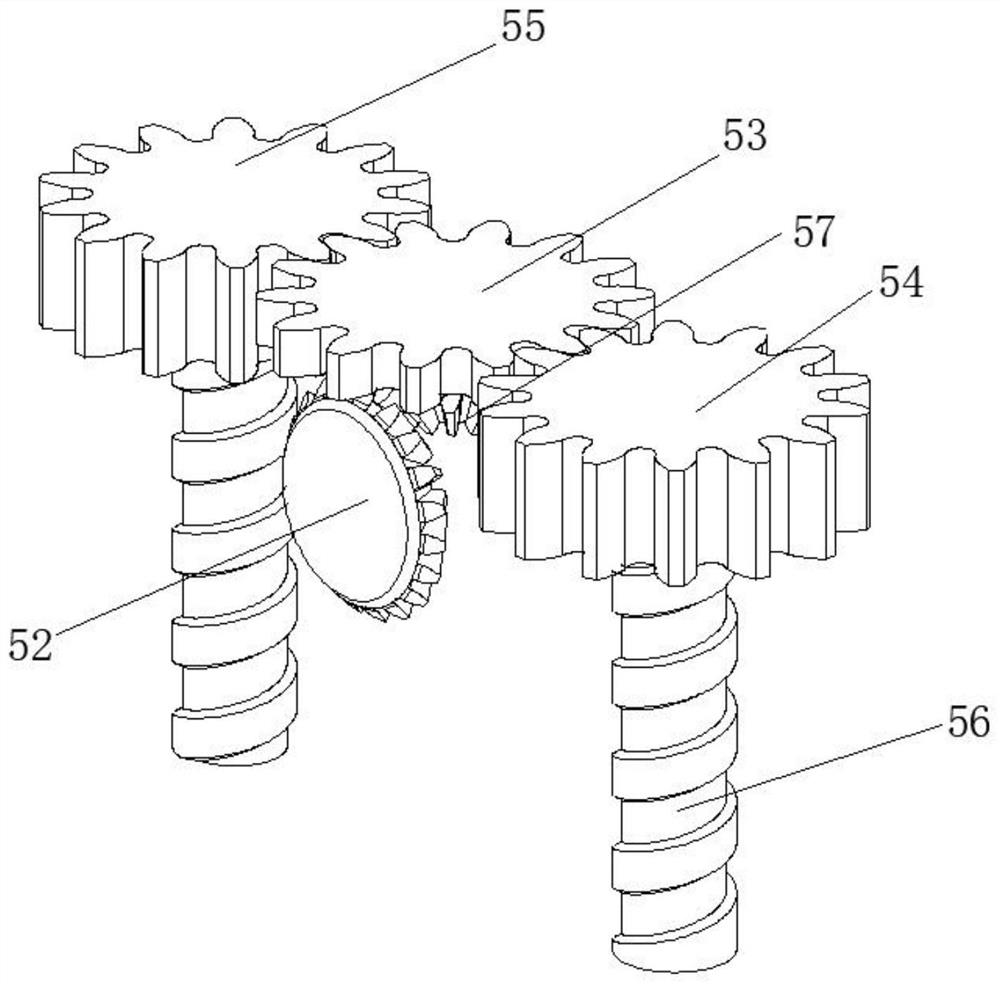

[0033] A fully automatic plate bending device, such as Figure 1-Figure 5 As shown, it includes a workbench 1, the top of the workbench 1 is welded with a support column 2, the top of the support column 2 is connected with an oil cylinder 3 through bolts, the inner wall of the support column 2 is slidably connected with a slide plate 4, and the front of the slide plate 4 is provided with an adjustment Mechanism 5, the front part of the support column 2 is provided with a protective mechanism 6, the top of the worktable 1 is provided with a discharge mechanism 7, and the discharge mechanism 7 is located on the right side of the support column 2, and the inside of the workbench 1 is provided with a discharge mechanism 8. The right side of the support column 2 is connected with the controller 10 by bolts, the inner wall of the slide plate 4 is slidably connected with a slider 11, the bottom of the slider 11 is welded with a top block 9, and the output end of the oil cylinder 3 is ...

Embodiment 2

[0040] like Figure 5-Figure 7 As shown, the lower surface of the scraper 71 is rotatably connected with the top of the table 1, the axis of the transmission gear 74 is rotatably connected with the inner wall of the support column 2, and the surface of the rack 75 is respectively connected with the support column 2 and the inner wall of the table 1. Sliding connection, after the bending is completed, the scraper 71 will reset, and at the same time it will push out the unloaded sheet, so that the worker does not need to manually take out the blank, which can increase the work efficiency, only need to keep feeding Yes, it can also reduce the occurrence of safety accidents, greatly increase the safety, and ensure the personal safety of workers.

[0041] It is worth noting that the unloading mechanism 8 includes a telescopic column 81, the surface of the telescopic column 81 is sleeved with a return spring 82, the top of the telescopic column 81 is welded with a limit block 83, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com