A double tension centering fixture

A centering fixture and tensioning technology, which is applied in the direction of expanding the mandrel, can solve problems such as workpiece deformation, and achieve the effects of improving the processing zero degree, avoiding the structure, and compacting the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

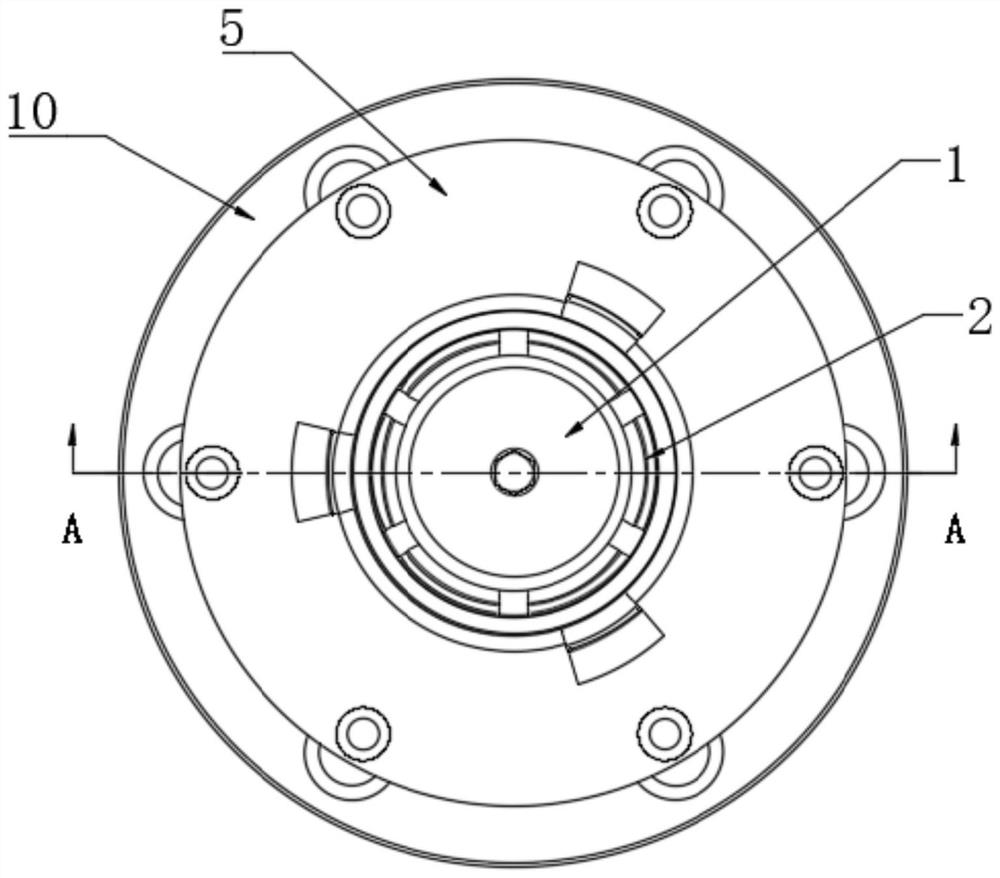

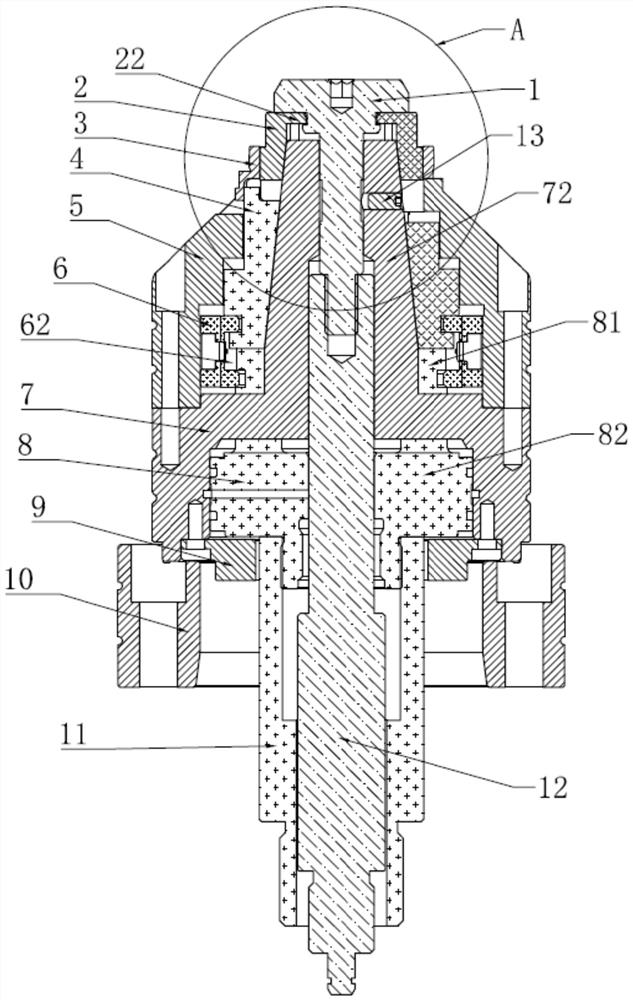

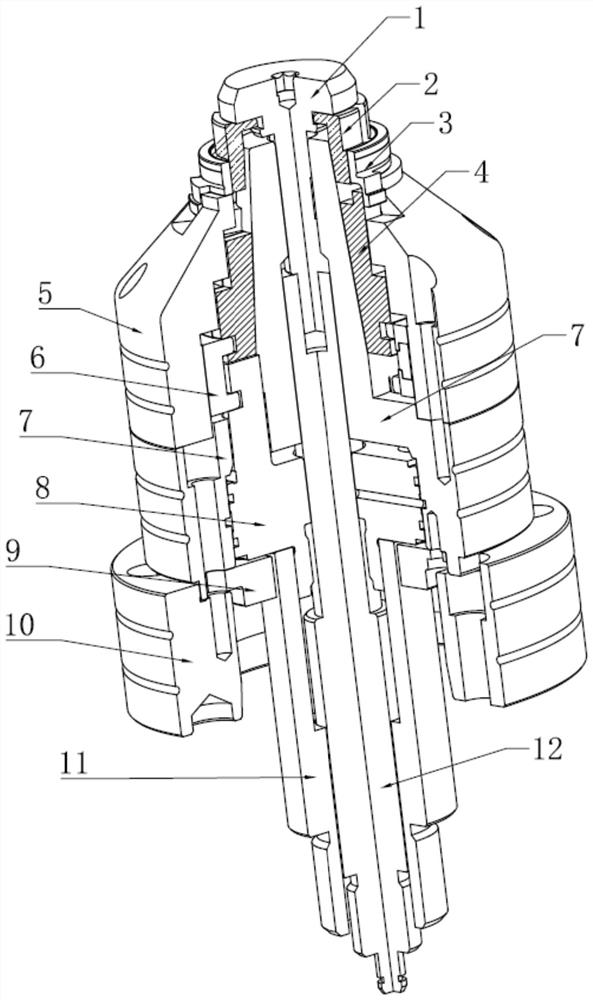

[0041] Such as Figure 1-Figure 5 A double tensioning centering fixture is shown, which includes: a fixed assembly fixedly connected to the machine tool, a first rubber expansion sleeve driving assembly for positioning the upper inner diameter surface of the thin-walled workpiece 3 with a step hole, and a first rubber expansion sleeve drive assembly for positioning the step hole The second rubber expansion sleeve drive assembly on the lower inner diameter surface of the thin-walled workpiece 3. The first rubber expansion sleeve drive assembly and the second rubber expansion sleeve drive assembly respectively pass the lifting movement relative to the fixed assembly, thereby driving the corresponding rubber expansion sleeve to tighten the different inner surfaces of the workpiece, so as to realize the precise positioning of the thin-walled workpiece with stepped holes .

[0042] In this example, Figure 10 A specific structure of a thin-walled workpiece 3 with a stepped hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com