Multi-degree-of-freedom mechanical arm

A technology of manipulators and degrees of freedom, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., and can solve problems such as falling objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

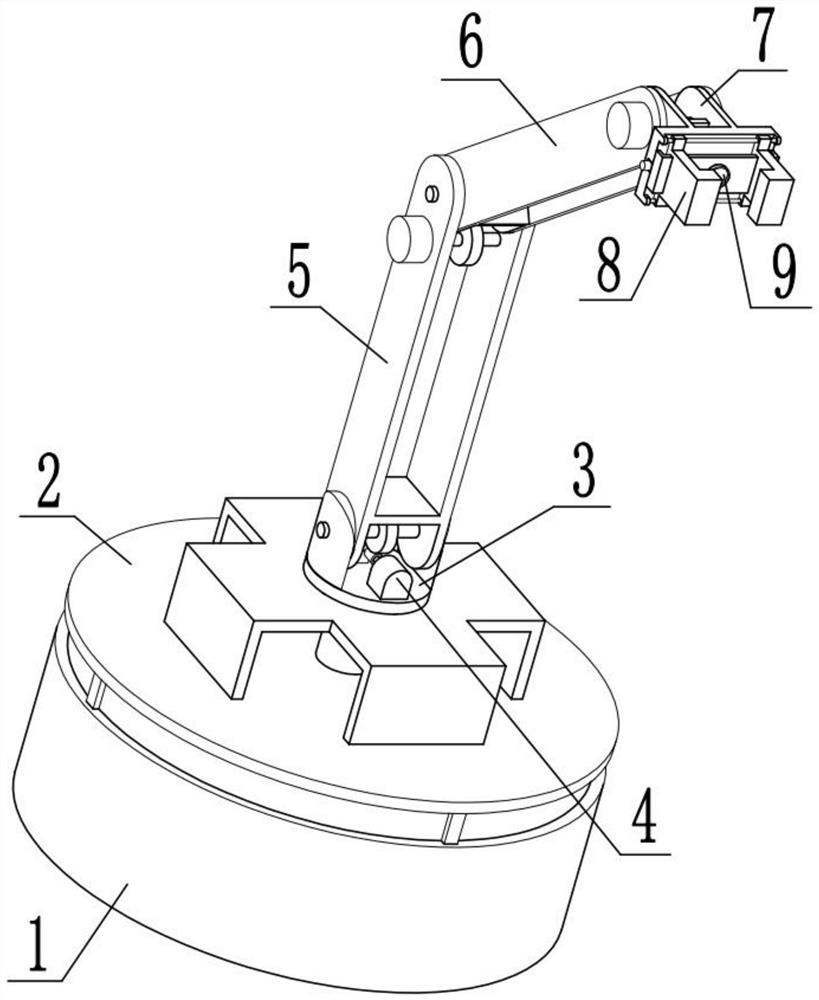

[0033] Combine below Figure 1-11This embodiment is described. The present invention relates to the technical field of manipulator equipment, more specifically, a multi-degree-of-freedom manipulator, including a load-bearing connection seat member 1, a lifting support member 2, a rotating connection seat member 3, an angle adjustment device 4, and a first-stage The power arm device 5, the secondary power arm device 6, the hinged connection seat member 7, the extrusion fixing device 8 and the vacuum adsorption device 9, the power arm can be adjusted through the transmission connection between the worm gear 5-3 and the worm 4-1 by using the motor II4-3 For the angle of I5-1, the angle of the power arm II6-1 can be adjusted by using the motor III5-6 through the gear II6-3 meshing with the gear I5-5, and the angle of the connecting seat 7-1 can be adjusted by starting the motor IV6-4. Two motors V7-5 can drive two extruding convex plates 8-2 to clamp and fix the article, and the s...

specific Embodiment approach 2

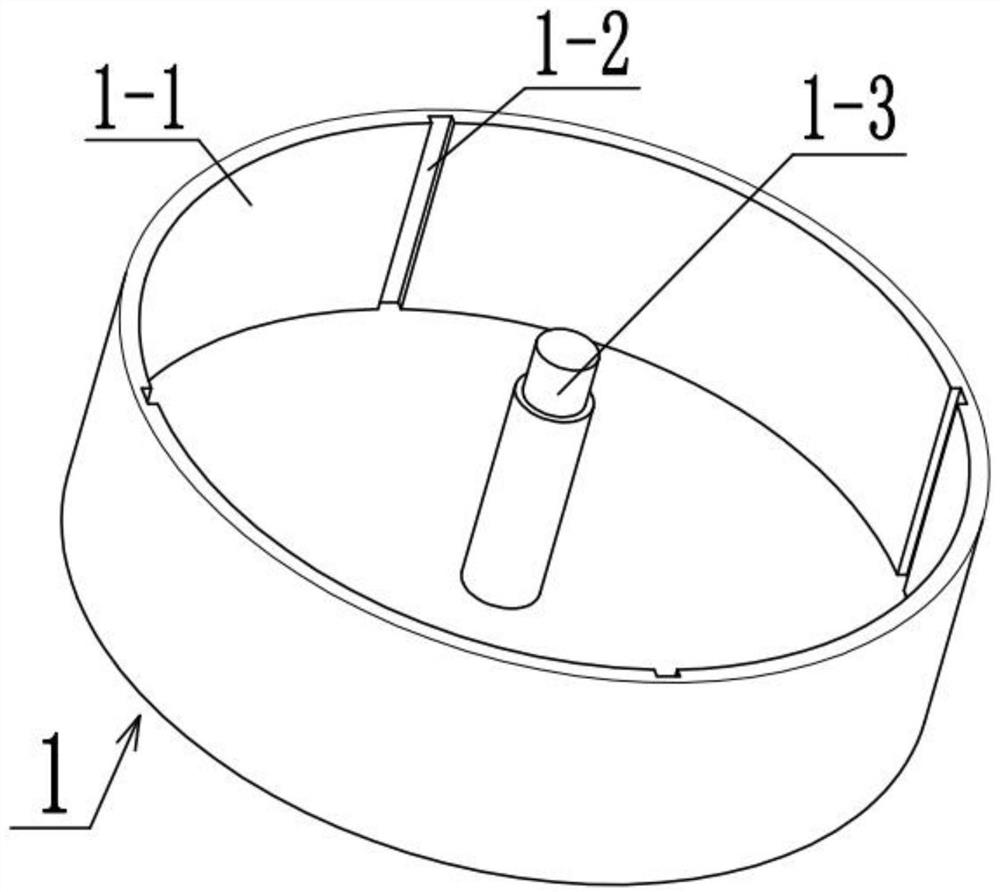

[0036] Combine below Figure 1-11 Describe this embodiment. This embodiment will further explain Embodiment 1. The load-bearing connection seat member 1 includes a connecting sliding cavity 1-1, a limit keyway 1-2, and an elevating and shrinking rod I1-3. The connecting sliding cavity 1-1 To play the role of load-bearing connection, four limit key grooves 1-2 are evenly arranged in the circumferential direction of the connecting sliding chamber 1-1, and the four limit key grooves 1-2 can provide sliding space for the lifting sliding column 2-1 and It limits the position, so that the lifting sliding column 2-1 can only slide up and down, and the connecting sliding chamber 1-1 is fixedly connected with the lifting rod I1-3, and the lifting rod I1-3 can be used to drive the bearing circular plate 2-2 to carry out Moving up and down.

specific Embodiment approach 3

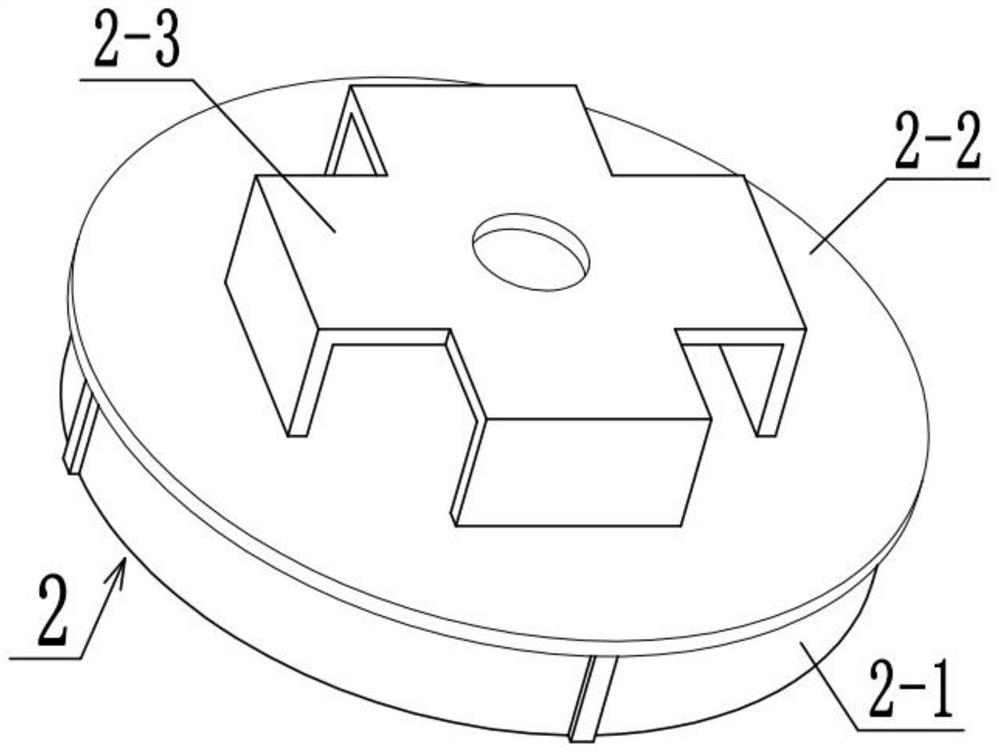

[0038] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the lifting support member 2 includes a lifting sliding column 2-1, a bearing circular plate 2-2 and a bearing seat I2-3, and the lifting sliding column 2-1 It plays the role of load-bearing connection. When the lifting sliding column 2-1 is slidably connected with the four limit keyways 1-2, the lifting sliding column 2-1 is limited, and the upper part of the lifting sliding column 2-1 is fixedly connected with a bearing circle. Plate 2-2, the load-bearing circular plate 2-2 plays the role of load-bearing connection, the lifting rod 1-3 is fixedly connected with the load-bearing circular plate 2-2, and the top of the load-bearing circular plate 2-2 is fixedly connected with the bearing seat I2-3 , The bearing seat I2-3 can provide a space for the adapter shaft 3-3 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com