Continuous cutting device for packaging paper

A cutting device and wrapping paper technology, applied in metal processing and other directions, can solve the problems of reduced production efficiency, unfavorable fast and efficient production, etc., and achieve the effects of convenient and fast adjustment, continuous cutting operations, and improved cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

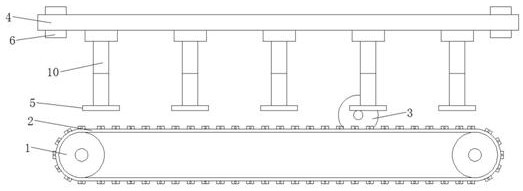

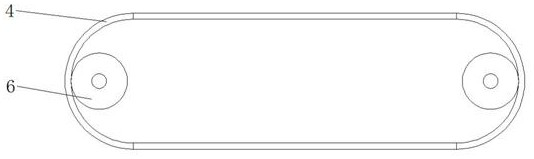

[0021] Referring to the drawings, in the embodiment of the present invention, a continuous cutting device for wrapping paper includes a driving roller 1, a conveyor belt 2, a cutting blade 3 and a bracket 4; the conveyor belt 2 is arranged horizontally, and the left and right ends of the conveyor belt 2 are It is wound on a horizontal driving roller 1, and a driving motor is connected to the driving roller 1, which drives the conveyor belt 2 to move, and conveys the wrapping paper placed on it to the right; the right end of the conveyor belt 2 is located on one side. Straight cutting blade 3, the cutting blade 3 is flush with the side piece of the conveyor belt 2, so that the wrapping paper placed on the conveyor belt 2 is moved and cut by the cutting blade 3 to achieve continuous cutting.

[0022] The conveyor belt 2 is provided with a placement groove 11 on the side facing the cutting blade 3, the placement groove 11 extends to the edge of the conveyor belt 2, and the depth o...

Embodiment 2

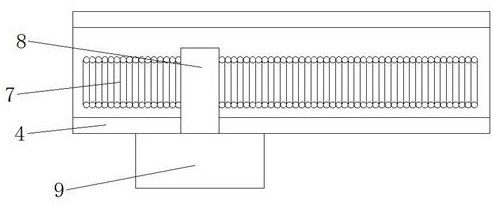

[0025] On the basis of Embodiment 1, the telescopic mechanism 10 includes a vertical sleeve 15 and a pressing rod 16 , and the sleeve 15 and the pressing rod 16 are coaxially arranged, and the pressing rod 16 extends from the lower end of the sleeve 15 into the interior , the upper end of the pressure rod 16 is fixedly installed with a piston 17 that cooperates with the inner wall of the sleeve 15, the lower end of the pressure rod 16 is fixedly connected with the pressure plate 5, and the upper part of the piston 17 is set as an inflatable cavity 18, by filling the inflatable cavity 18 with suitable The pressure of the pressure plate 5 to the lower wrapping paper is changed, and it can be adjusted according to different thicknesses; the top of the sleeve 15 is provided with an inflatable air nozzle 19 that communicates with the inflatable cavity 18, and the inflation air nozzle 19 can be used to inflate the air The chamber 18 is inflated or deflated to change the internal air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com