An automatic delivery system

An automatic and cargo technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of heavy workload of staff and prone to errors, reduce energy consumption, reduce the possibility of data errors, and improve green environmental performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

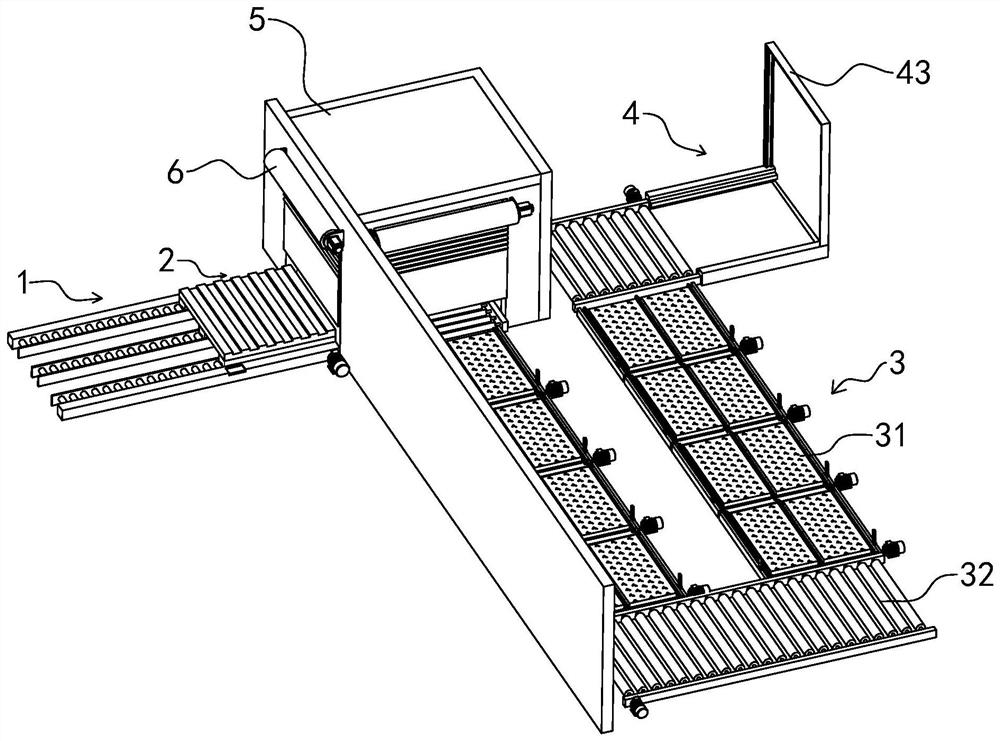

[0036] The present application discloses an automatic receiving system.

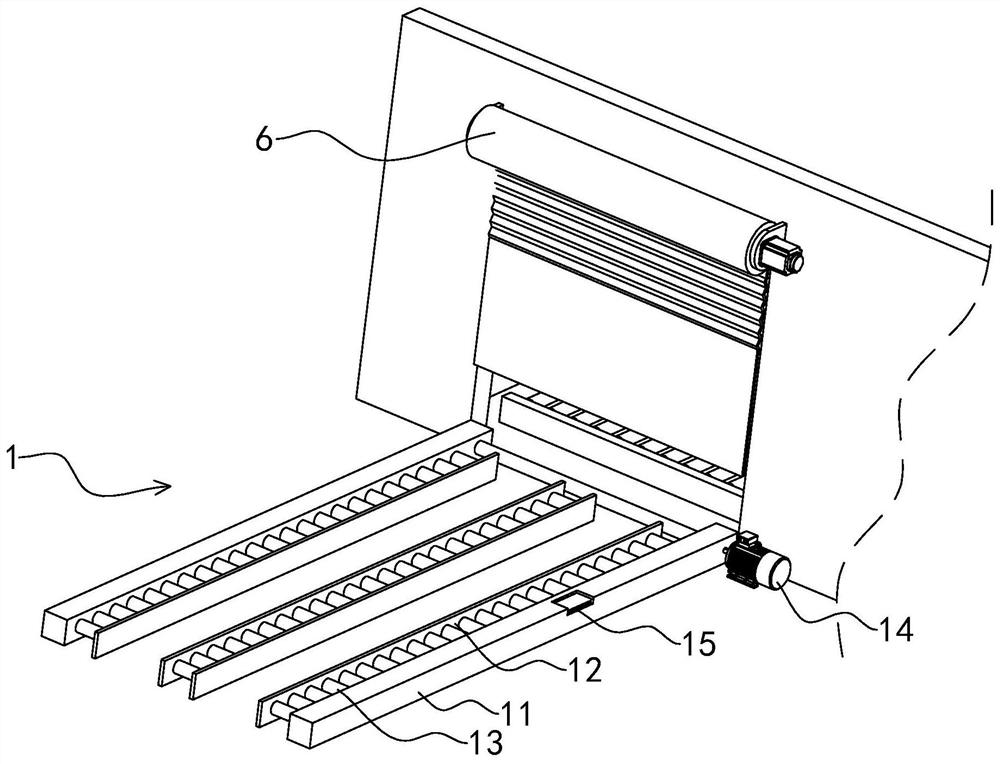

[0037] refer to figure 1 One automatic shipping system includes a transfer device 1 for the launcuit to the truck to the receiving material and input within the warehouse, and transporting device 2 for supporting and placing the goods, the inner side of the warehouse is close to the delivery device 1 Chamber 5, the discharge end of the transition chamber 5 is provided with a conveying device 3 for conveying the cargo, the transition chamber 5 is adjacent to the conveying device 3, and the fast roller blind 6 is provided on one side of the delivery device 1, and the fast roller blind 6 is set to open. .

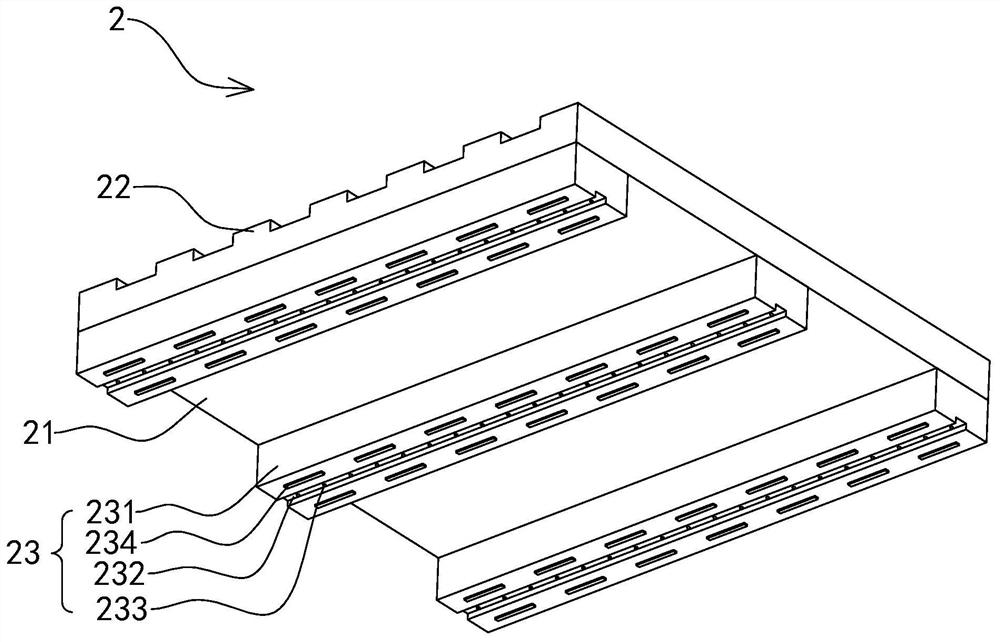

[0038] refer to figure 2 The transport device 2 includes three parallel arranged support mechanisms 23, and the support mechanism 23 includes a seat body 231, and the bottom surface of the seat body 231 is provided with a groove 232 disposed in the traveling direction of the transport device 2, and the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com