A kind of copper ion antibacterial fiber and antibacterial fabric

An antibacterial fiber and copper ion technology, applied in the field of fiber manufacturing, can solve the problem of high cost and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

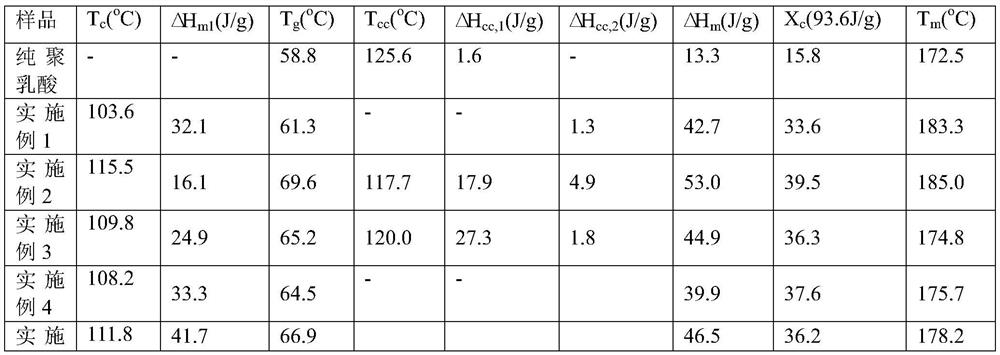

Examples

Embodiment 1

[0043] A copper ion antibacterial fiber, said fiber comprises the following components in parts by weight: 100 parts of polylactic acid slices, 5 parts of copper-loaded phosphorus-containing nanoporous phosphorus-containing borosilicate ceramic powder, maleic anhydride modified polyvinyl alcohol ( 5 parts of maleic anhydride grafted (1.5 wt%), 1 part of silane-terminated polyethylene glycol, 1 part of triethylene glycol acrylate, and 0.01 part of initiator 1173.

[0044] The preparation method of copper-loaded phosphorus-containing nanoporous phosphorus-containing borosilicate ceramic powder is as follows:

[0045] (1) Preparation of precursor: Weigh raw materials according to the following mass ratio: phenyltrimethoxysilane: trimethylolphosphine oxide: diphenyldimethoxysilane: boric acid: hexamethyldisiloxane: water : Concentrated hydrochloric acid=100:5:10:10:5:15:3, stirred at room temperature for 1 hour, then refluxed for 3 hours, and finally removed water and oligomers fo...

Embodiment 2

[0054] A copper ion antibacterial fiber, said fiber comprises the following components in parts by weight: 100 parts of polylactic acid slices, 15 parts of copper-loaded phosphorus-containing nano-porous phosphorus-containing borosilicate ceramic powder, maleic anhydride modified polyvinyl alcohol ( Maleic anhydride grafting amount is 3.5wt%) 10 parts, 5 parts of silane-capped polyethylene glycol, 3 parts of diethylene glycol methacrylic acid acrylate, 0.5 part of initiator 9070 and heat stabilizer calcium stearate 3 parts share.

[0055] The preparation method of copper-loaded phosphorus-containing nanoporous phosphorus-containing borosilicate ceramic powder is as follows:

[0056] (1) Preparation of precursor: Weigh raw materials according to the following mass ratio: phenyltrimethoxysilane: trimethylolphosphine oxide: diphenyldimethoxysilane: boric acid: hexamethyldisiloxane: water : Concentrated hydrochloric acid = 100: 10: 30: 15: 10: 20: 5, stirred at room temperature f...

Embodiment 3

[0065] A copper ion antibacterial fiber, said fiber comprises the following components in parts by weight: 100 parts of polylactic acid slices, 10 parts of copper-loaded phosphorus-containing nanoporous phosphorus-containing borosilicate ceramic powder, maleic anhydride modified polyvinyl alcohol ( Maleic anhydride grafting amount is 2wt%) 5-10 parts, 2 parts of silane-capped polyethylene glycol, 2 parts of triethylene glycol dimethacrylate, 6590.03 parts of initiator and heat stabilizer stearic acid 2 parts lead.

[0066] The preparation method of copper-loaded phosphorus-containing nanoporous phosphorus-containing borosilicate ceramic powder is as follows:

[0067] (1) Preparation of precursor: Weigh raw materials according to the following mass ratio: phenyltrimethoxysilane: trimethylolphosphine oxide: diphenyldimethoxysilane: boric acid: hexamethyldisiloxane: water : Concentrated hydrochloric acid=100:8:20:12:8:18:4, stirred at room temperature for 2 hours, then refluxed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com