Automatic cleaning and collecting device suitable for sewage pipes with different diameters

A technology for automatic cleaning and collection devices, applied in water supply devices, cleaning sewer pipes, waterway systems, etc., can solve the problems of fast sewage flow, increase sewage flow space, hinder normal drainage of sewage pipes, etc., and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

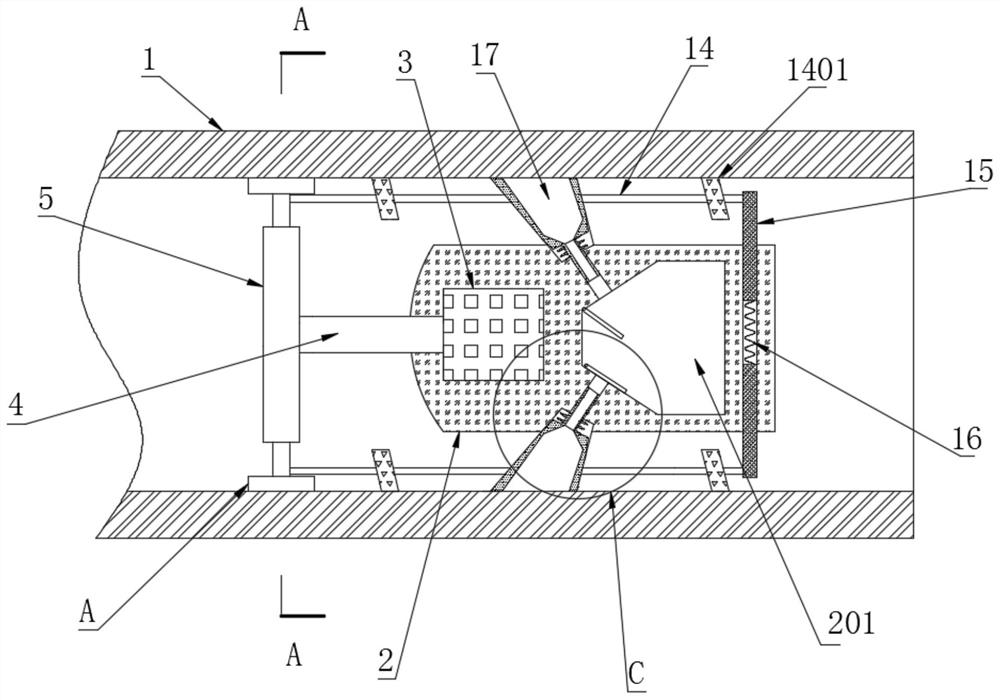

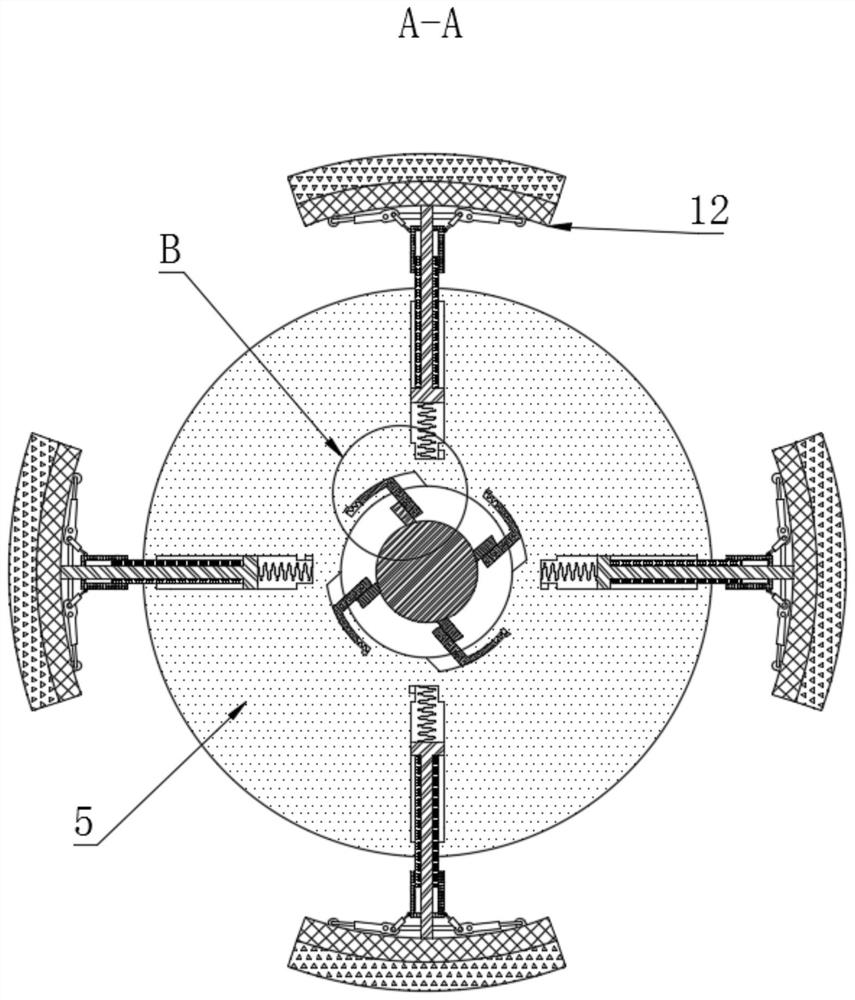

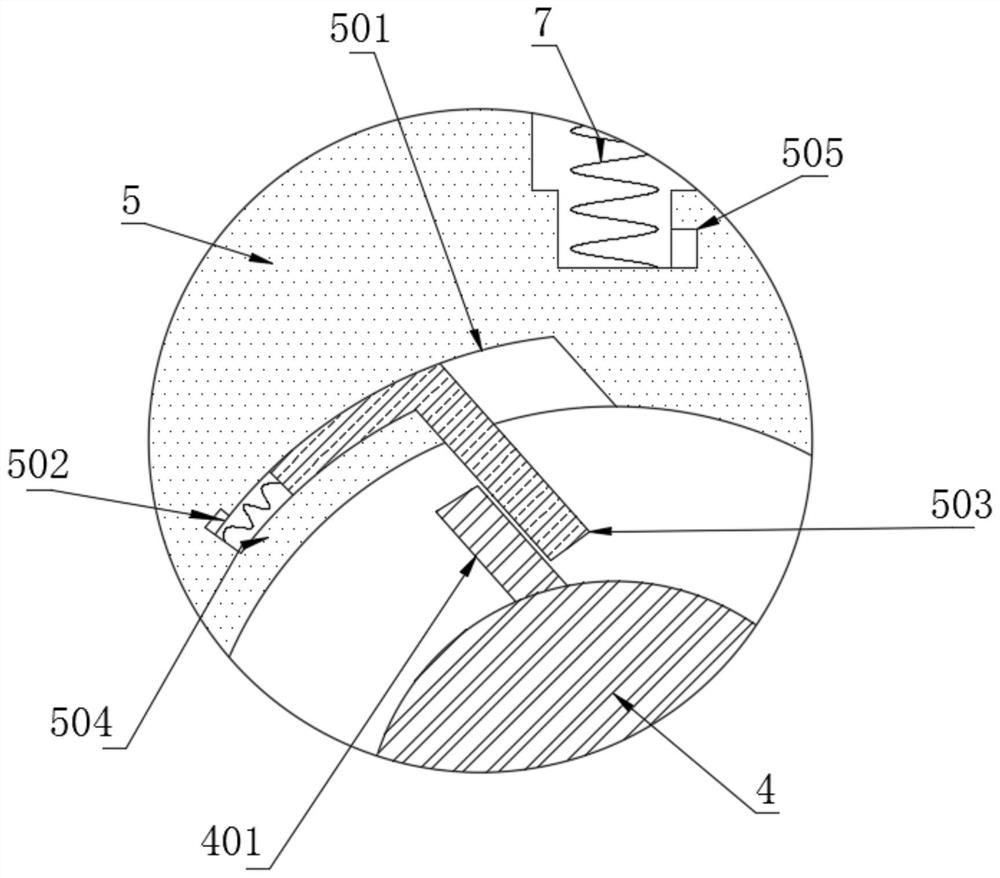

[0026] Embodiment: an automatic cleaning and collecting device for sewage pipes of different diameters, comprising a sewage pipe 1, a cleaning frame 2 is arranged inside the sewage pipe 1, and a collection chamber 201 is provided on the right side of the interior of the cleaning frame 2, and the collection chamber The left part of 201 is in the shape of a tightened cone, so as to ensure that the collected sundries slide down to the right side of the collection cavity 201 through centrifugal extrusion. The inner left side of the cleaning frame body 2 is fixedly connected with the drive unit 3, the left end of the drive unit 3 is rotatably connected with the drive shaft 4, the left side of the drive shaft 4 is provided with a fixed baffle plate 401, and the outside of the fixed baffle plate 401 is provided with a circle Disk 5, the inner wall of the disk 5 is surrounded by an arc-shaped groove 501, and the inside of the disk 5 is provided with a first communication groove 502 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com