Pot rack, gas stove and processing method of pot rack

A processing method and technology for pot racks, which are applied in the field of gas stoves, can solve problems such as heat loss and poor energy gathering effect of pot racks, and achieve the effects of reducing heat loss, reducing heat loss and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

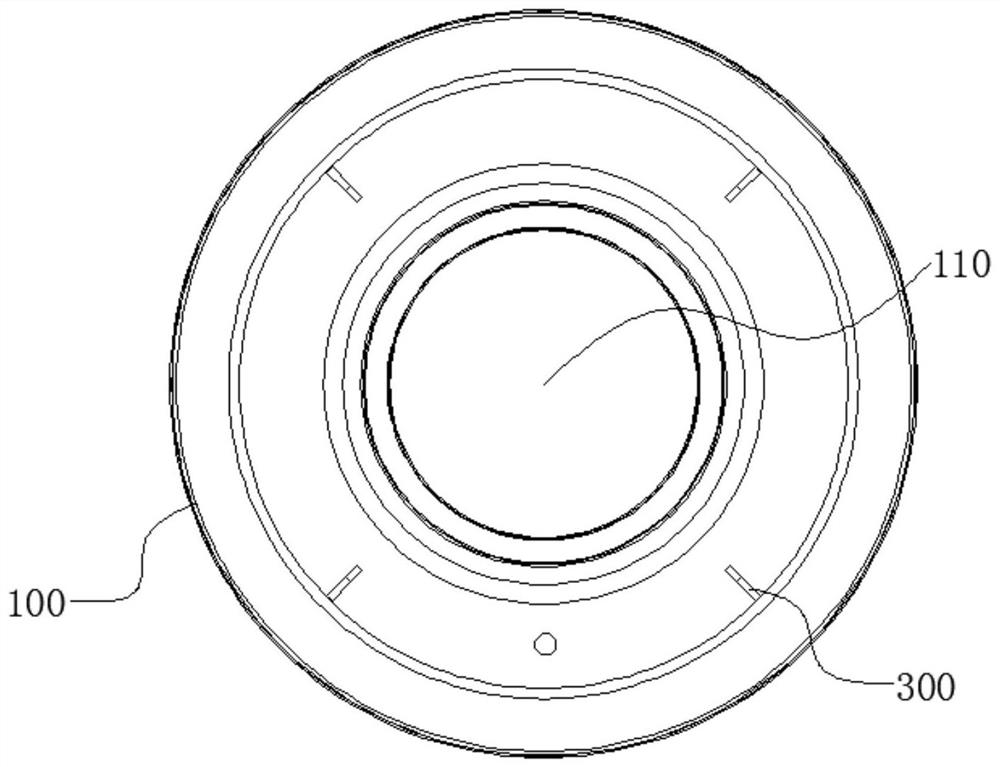

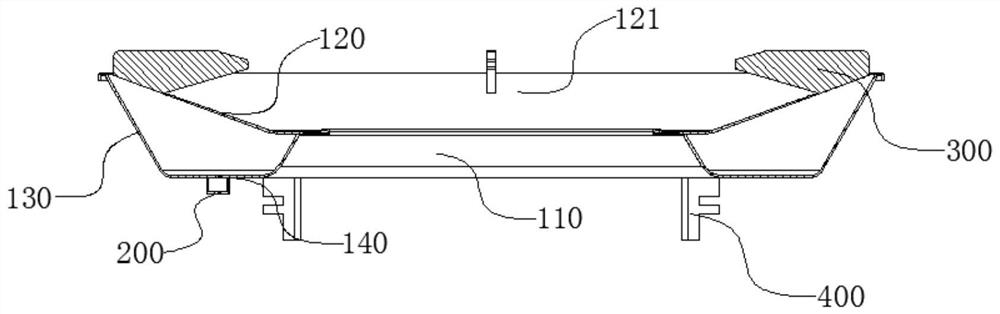

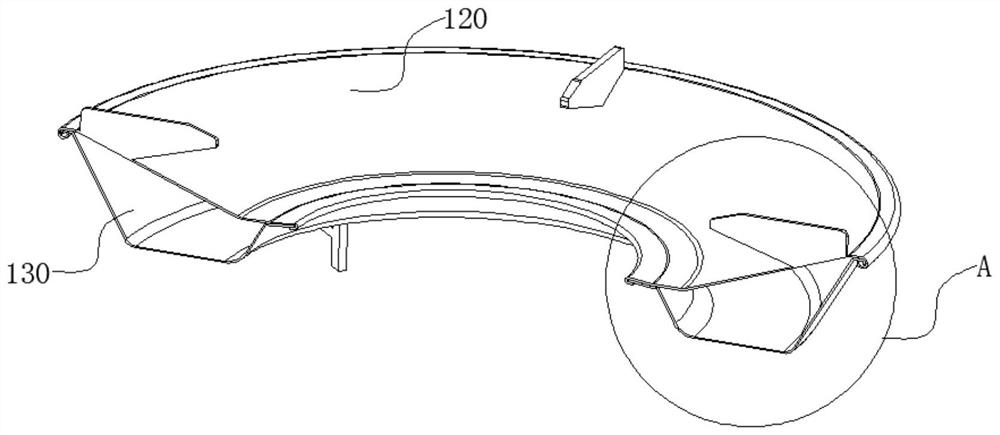

[0050] This embodiment provides a pot support, such as figure 1 and figure 2 As shown, it includes a body 100. The middle part of the body 100 has a through hole 110 for passing through the burner. The body 100 includes a top plate 120 and a bottom plate 130. The top plate 120 and the bottom plate 130 are surrounded by a closed cavity; the outer surface of the top plate 120 forms a The open energy gathering chamber 121 communicates with the through hole 110 .

[0051]For the pan support provided in this embodiment, when in use, the burner penetrates the body 100 through the bottom of the through hole 110, and the flame in the burner burns to generate heat. During this process, the energy gathering chamber 121 on the outer surface of the top plate 120 can It plays the role of collecting heat to reduce the loss of heat at the opening; moreover, the top plate 120 and the bottom plate 130 in the pot frame are surrounded by a closed cavity, because the thermal conductivity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com