Chemical heat exchanger for chemical production

A technology for chemical production and heat exchangers, applied in heat exchanger shells, heat transfer modification, heat exchange equipment, etc., can solve problems such as difficult cleaning of heat exchangers, uneven temperature of heat exchanger liquids, etc., to avoid contamination Scale, convenient liquid circulation, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

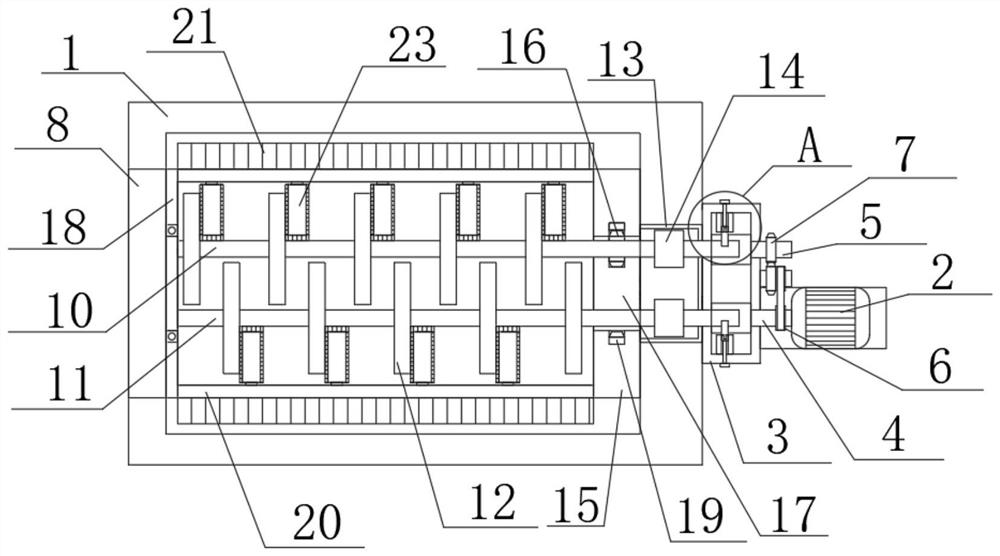

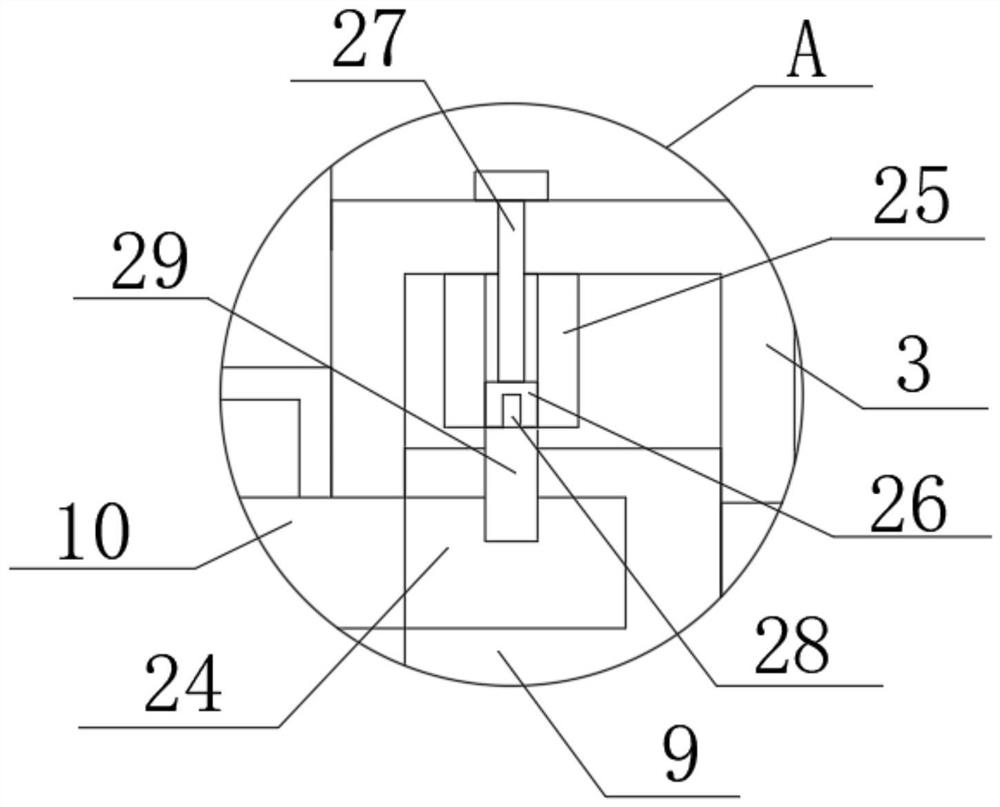

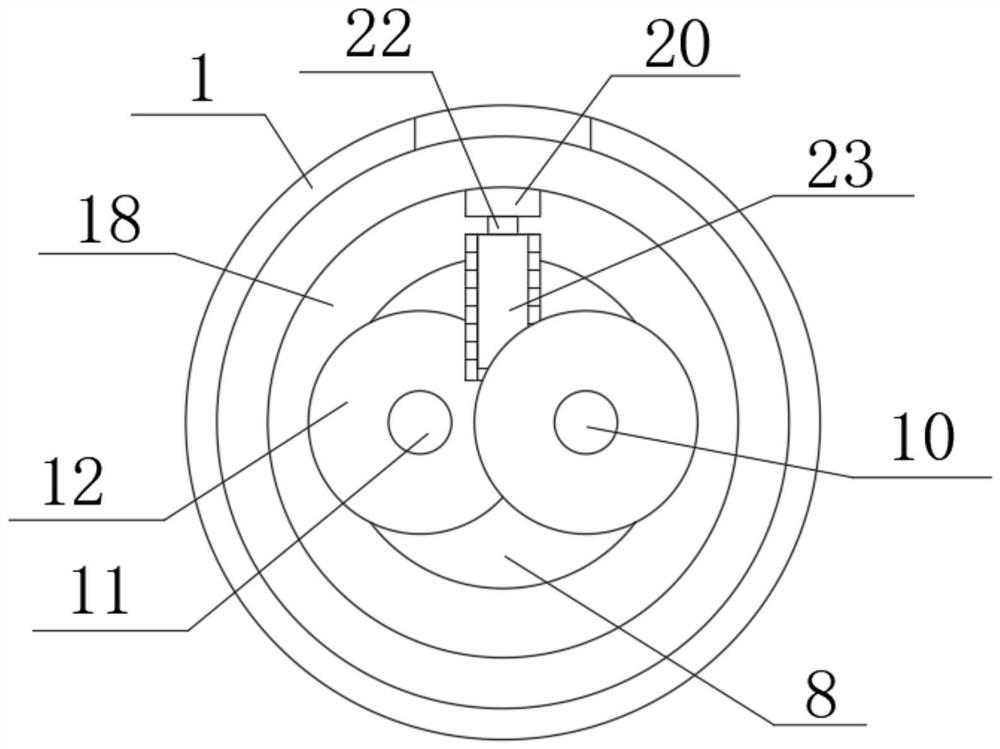

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0025] refer to Figure 1-4 , a chemical heat exchanger used in chemical production, comprising a heat exchanger shell 1 and a motor 2, the heat exchanger shell 1 is provided with a water inlet and a water outlet, the side wall of the heat exchanger shell 1 is provided with a connection box 3, connected The side wall of the box 3 away from the heat exchanger shell 1 is fixedly connected with the motor 2, the output head of the motor 2 is fixedly connected with the first rotating rod 4, the first rotating rod 4 runs through the connecting box 3, and the connecting box 3 is close to the side wall of the motor 2 Rotationally connected with the second rotating rod 5 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap