A fast air-drying device for furniture spray paint

An air-drying device and furniture spraying technology, which can be used in devices for coating liquids on surfaces, pre-treatment surfaces, coatings, etc., and can solve the problems of long leveling time, harm to workers' health, and decreased painting efficiency, and achieve a high level of quality. Conducive to paint drying, increasing contact surface and accelerating air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

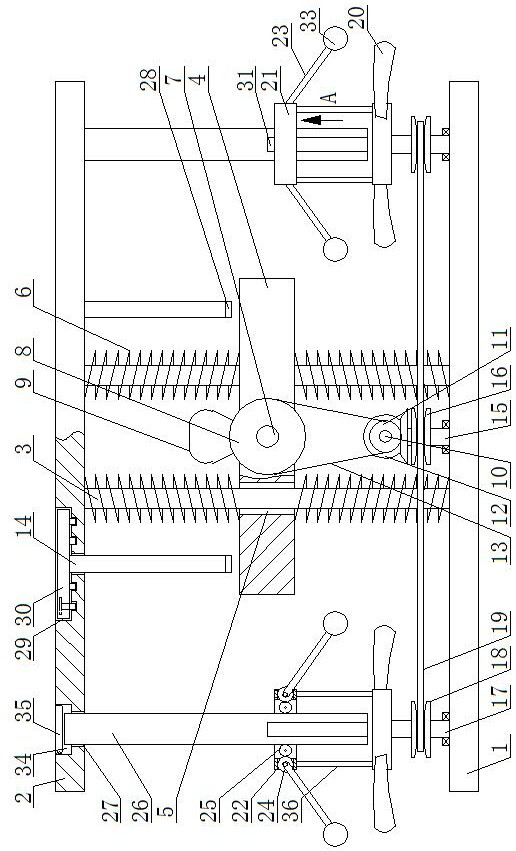

[0017] Specifically, as shown in FIG. 1 , the lower ends of the vertical rods 14 described in this embodiment are all fixedly installed with a film 28. when activity

[0020] Further, as shown in FIG. 1 , the pendulum 33 is fixedly installed at the other end of the pendulum rod 23 described in this embodiment. put

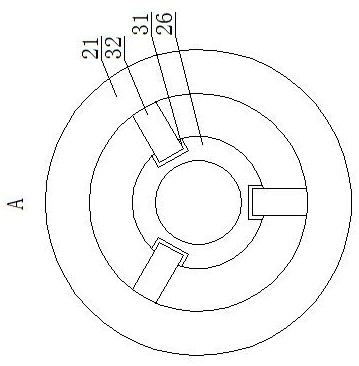

[0022] Further, as shown in Figure 1, the impeller 20 described in this embodiment and the ring 21 are connected by several connecting rods 36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com