Novel intelligent plastic manufacturing device

An intelligent manufacturing and plastic technology, applied in the field of plastic production, can solve the problems of poor equipment continuity, increase production costs, slow water volatilization, etc., and achieve the effects of low purchase cost, improved work efficiency, and rapid volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

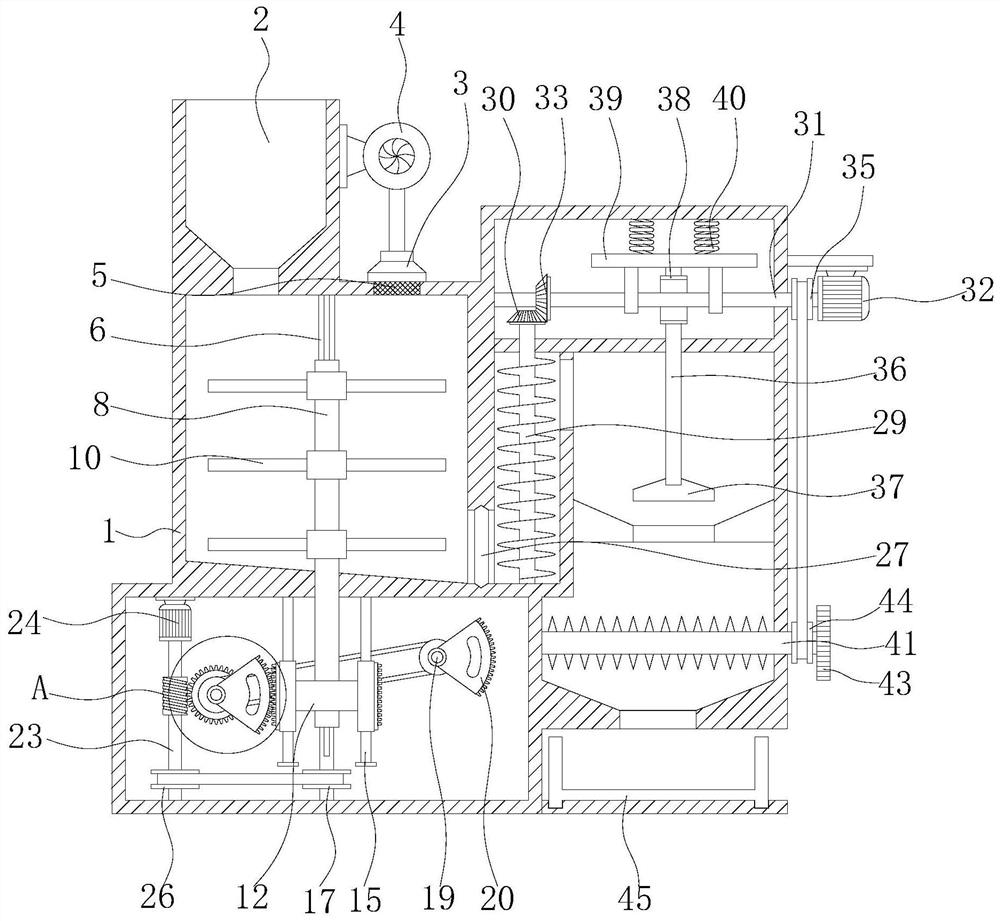

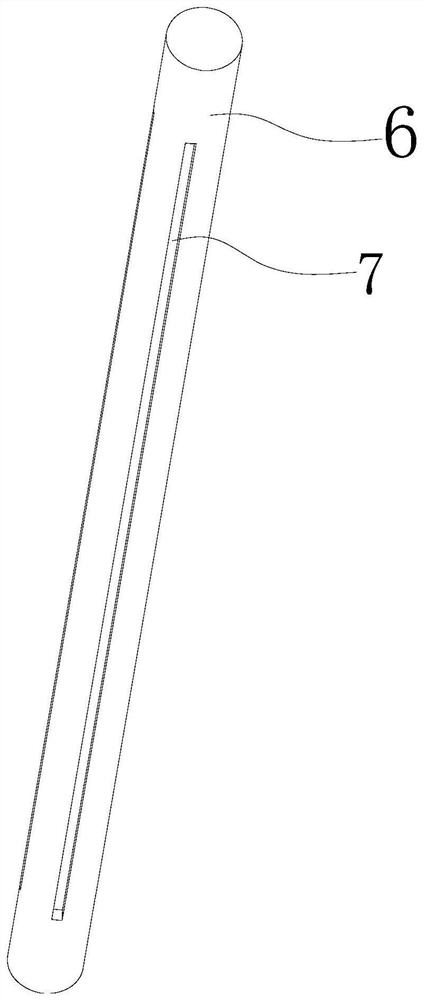

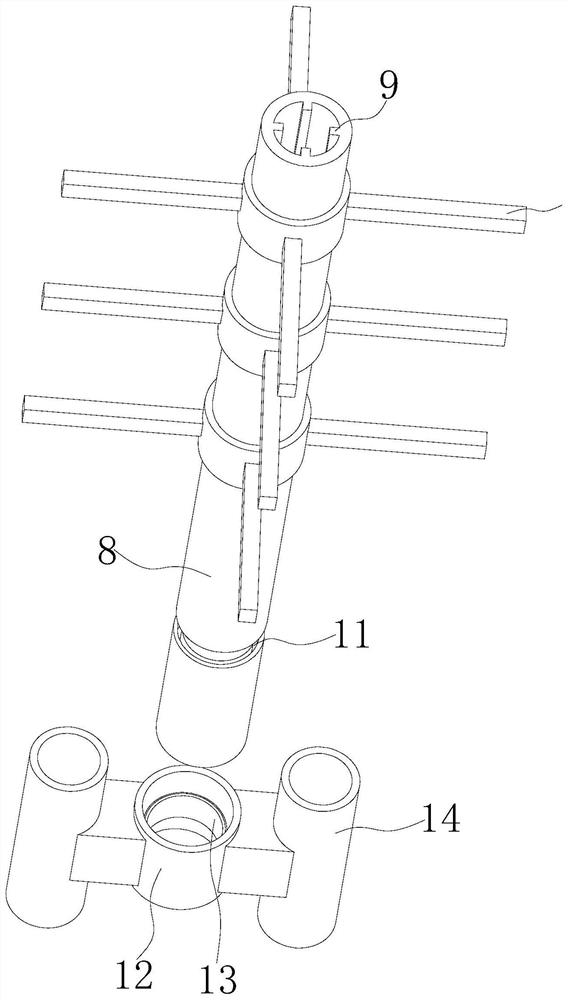

[0029] see Figure 1-7, the present invention provides a technical solution: a new type of intelligent manufacturing and production of plastic devices, including a box body 1, a ventilation hood 3 is fixedly installed on the top of the box body 1, and a hot air blower 4 is connected to the top of the ventilation hood 3 through a pipeline. The top of the body 1 is fixedly installed with a filter screen 5, the inside of the box body 1 is sleeved with a transmission rod 6, and the outside of the transmission rod 6 is provided with a strip groove 7, and the outside of the transmission rod 6 is sleeved with a lifting rod 8, and the lifting rod 8 The inner wall of the lifting rod 8 is fixedly equipped with a strip protrusion 9, the outside of the lifting rod 8 is fixedly installed with a stirring bar 10, the outside of the bottom of the lifting rod 8 is provided with an annular connection groove 11, and the outside of the bottom of the lifting rod 8 is sleeved with a connecting sleev...

Embodiment 2

[0032] see Figure 1-7 , On the basis of Embodiment 1, the present invention provides a technical solution: a feeding hopper 2 is fixedly installed at one end of the top of the box body 1, and the hot air blower 4 is fixedly connected with the feeding hopper 2.

[0033] In this embodiment, by setting the feed hopper 2, the plastic raw material is poured into the inside of the box body 1 through the feed hopper 2, and then the production work can be carried out. , so that the position of the hot air blower 4 is fixed, so that the hot air blower 4 can operate stably.

Embodiment 3

[0035] see Figure 1-7 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the specifications and sizes of the strip-shaped protrusions 9 and the strip-shaped grooves 7 are matched and the number is the same, and the strip-shaped protrusions 9 are slidably installed on the Inside the strip groove 7 , the annular connecting plate 13 is adapted to the size of the annular connecting groove 11 , and the annular connecting plate 13 is movably installed inside the annular connecting groove 11 .

[0036] In this embodiment, when the first driving motor 24 is in operation, by rotating the transmission rod 6, due to the sliding connection between the strip-shaped protrusion 9 and the strip-shaped groove 7, the lifting rod 8 changes to drive the stirring bar 10 to rotate. At the same time, due to the connection between the annular connecting plate 13 and the annular connecting groove 11, the connecting sleeve 12 will not rotate under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com