Universal blow molding mold for uniform machining

A blow mold, uniform technology, applied in the field of general blow mold, can solve the problem that the plastic parison cannot be formed with uniform thickness, and achieve the effect of convenient cooling process, accelerated processing, and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

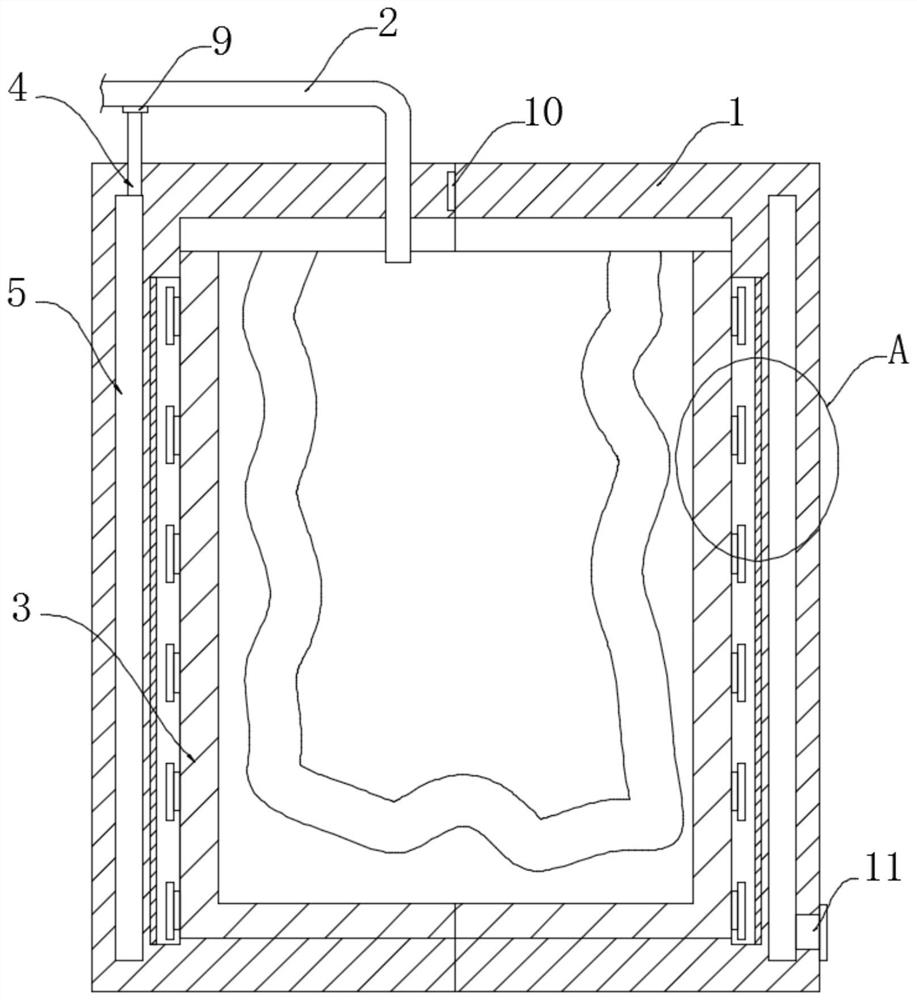

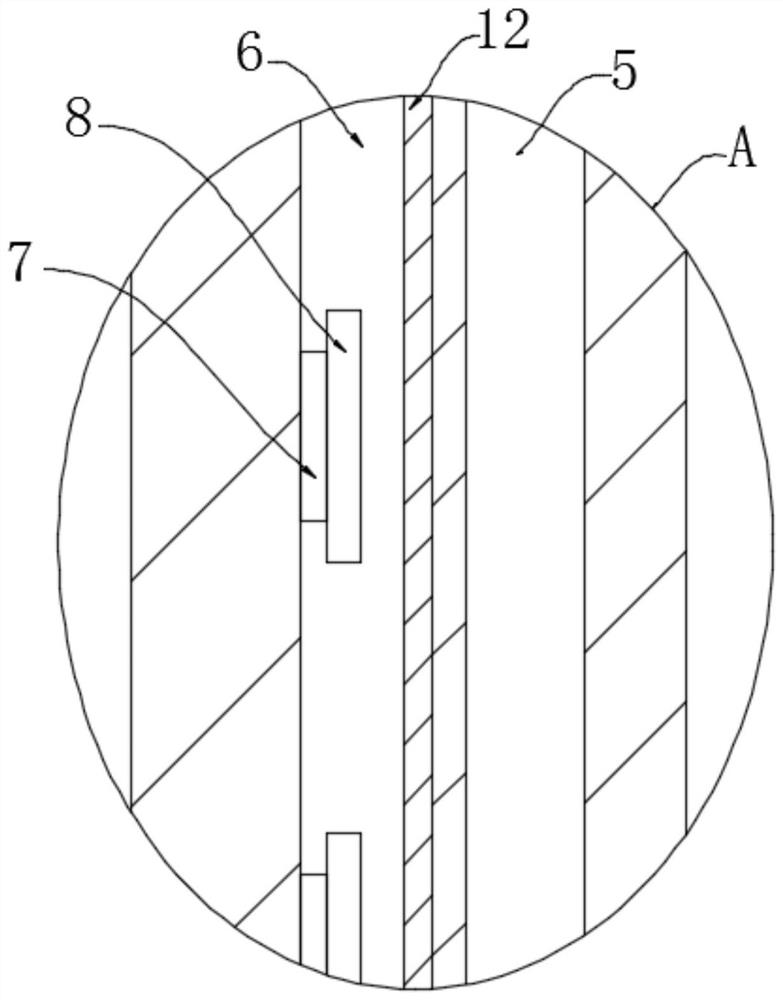

[0022] refer to Figure 1-2 , a uniformly processed general-purpose blow molding mold, including a base body 1, the base body 1 is divided into two half parts, the two half parts are fixed to each other by a buckle structure, and the inside of the two half parts are common A mold cavity is opened and a mold cover 3 is fixedly connected in the mold cavity. A connecting layer 6 is provided on the upper side of the mold cover 3, and an air injection pipe 2 is inserted in the connection layer 6. The air injection pipe 2 runs through the top wall of the base body 1 and is connected with the It communicates with the external high-pressure air pump. The base body 1 is provided with an annular circulation chamber 5, and the outer side of the cavity is provided with a fixed groove 6. The side of the fixed groove 6 close to the mold casing 2 is provided with multiple sets of heat exchange structures;

[0023] Each set of heat exchange structures includes a piezoelectric sheet 7 symmetri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap