Double-section bearing type normal-pressure tank truck

A load-bearing and liquid tank truck technology, which is applied in the direction of oil tank trucks, motor vehicles, and article transport vehicles, can solve the problems of inconvenient repair and maintenance, and achieve the effects of saving materials, reducing self-weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

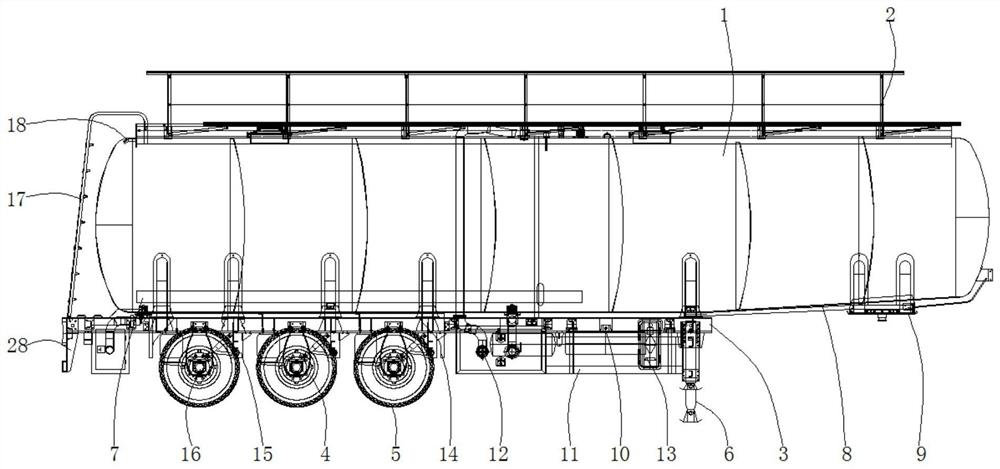

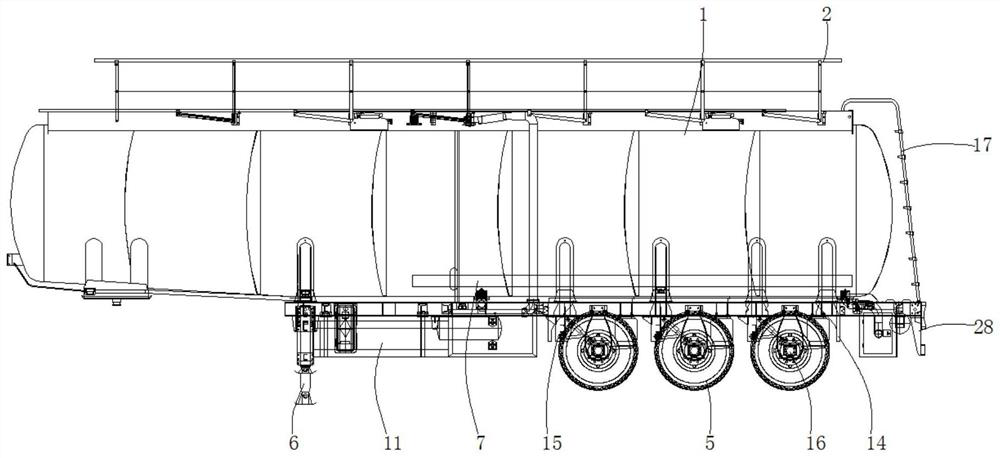

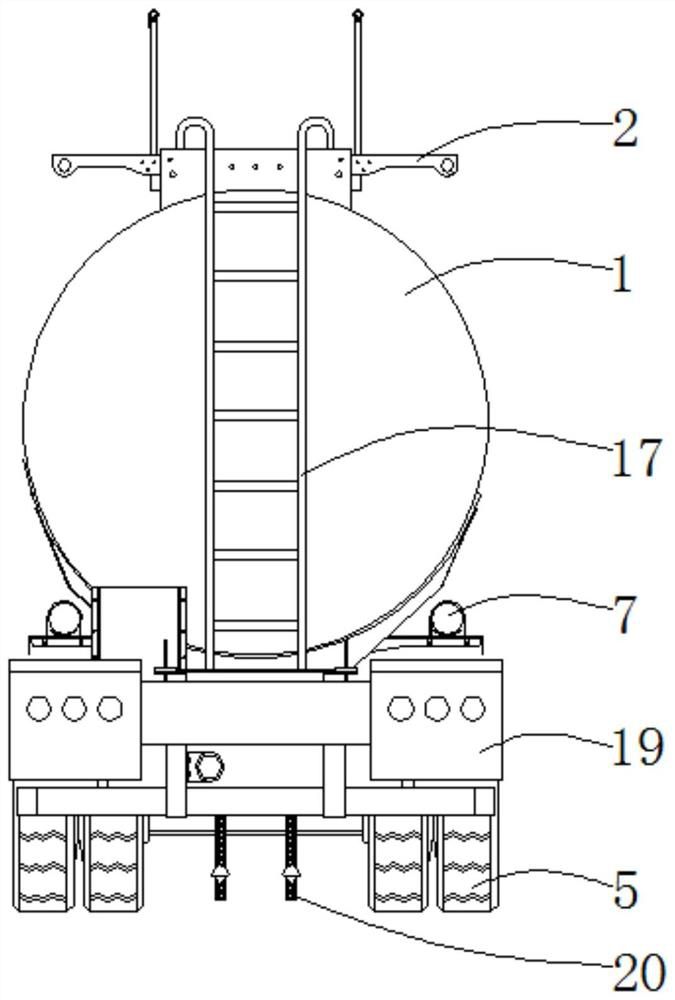

[0033] see Figure 1-5 , the present invention provides a technical solution: a double-stage bearing type atmospheric pressure liquid tank truck, including a tank body 1, the tank body 1 includes a first liquid tank 101 and a second liquid tank 102, and the first liquid tank 101 It is fixedly connected with the opposite side of the second liquid tank 102, the top of the outer surface of the tank body 1 is fixedly connected with a coaming plate 2, the bottom of the outer surface of the tank body 1 is fixedly installed with a frame 3, and the vehicle One side of the bottom of the frame 3 is fixedly equipped with a disc brake shaft 16, and the front and rear ends of the disc brake shaft 16 are fixedly connected with the hub 4, the outer surface of the hub 4 is provided with a tire 5, and the outer surface of the tank body 1 The bottom and one side of the vehicle frame 3 are fixedly connected with a supporting device 6, and the front and rear sides of the outer surface of the tank...

no. 2 example

[0049] Please refer to Image 6 , Figure 7 and Figure 8 , based on the double-stage load-bearing atmospheric pressure tank truck provided in the first embodiment of the present application, the second embodiment of the present application proposes another double-stage load-bearing atmospheric pressure liquid tank truck. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0050] Specifically, the difference between the double-stage load-bearing atmospheric tank truck provided by the second embodiment of the present application is that an installation groove 24 is opened in the middle of the top of the ladder 17, and the front and rear sides of the inner surface of the installation groove 24 are Both are connected with card slots 25, the middle of the top of the ladder 17 is provided with an anti-slip assembly 26, the anti-slip assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com