Distillation type sewage treatment device

A technology of sewage treatment device and installation block, applied in heating water/sewage treatment, grain treatment, etc., can solve the problems of single function, wasteful design, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

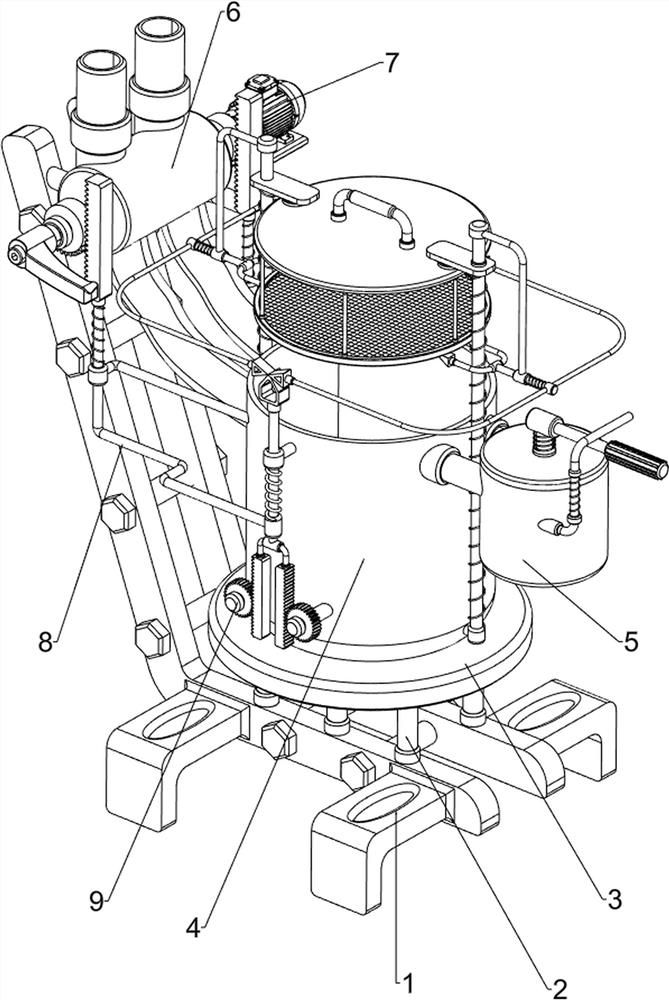

[0071] A distillative sewage treatment device, such as figure 1 As shown, it includes a support foot 1, a first pillar 2, a heating plate 3, a distillation mechanism 4 and a discharge mechanism 5, and the top of the foot 1 is provided with six first pillars 2, and the tops of the six first pillars 2 are connected with a heating plate 3 for heating A distillation mechanism 4 is arranged on the top of the plate 3, and a discharge mechanism 5 is arranged on the distillation mechanism 4.

[0072] When people need to treat sewage, first people make the distillation mechanism 4 run, then pour sewage into the distillation mechanism 4, then people turn on the heating plate 3, and the heating plate 3 heats part of the distillation mechanism 4, so that the distillation mechanism The sewage in 4 gradually evaporates, and then the water vapor flows into the discharge mechanism 5, and the discharge mechanism 5 makes it condense into liquid water, and collects it. When it is water, people ...

Embodiment 2

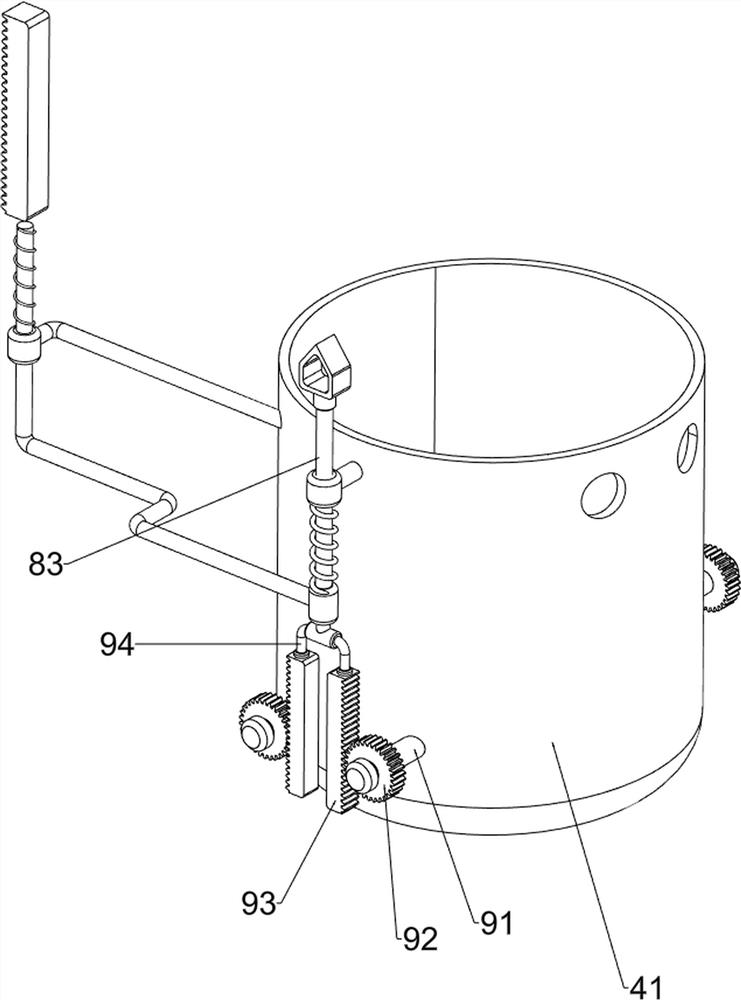

[0074] On the basis of Example 1, such as figure 2 and image 3 As shown, the distillation mechanism 4 includes a distillation frame 41, a first sliding rod 42, a cover plate 43, a first handle 44, a first spring 45, a first sliding sleeve 46, a second sliding rod 47, a wedge 48 and a second Spring 49, the top of the heating plate 3 is provided with a distillation frame 41, the bottom of the distillation frame 41 is provided with a first slide bar 42 on the front and rear sides, and a cover plate 43 is slidably connected between the first slide bars 42 on the front and rear sides. 43 is provided with a first handle 44 in the middle of the top side, and a first spring 45 is wound on the first slide bar 42 on the front and rear sides, the top of the first spring 45 is connected with the cover plate 43, and the bottom of the first spring 45 is connected with the first slide bar 42 connection, the top of the first slide bar 42 on the front and rear sides is provided with the fir...

Embodiment 3

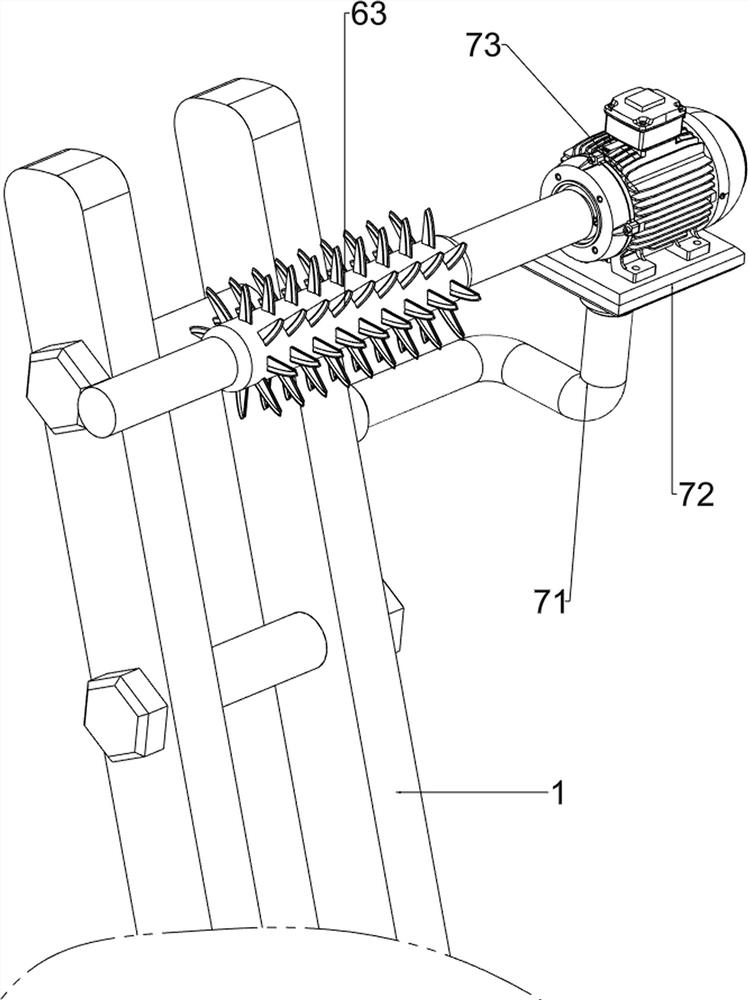

[0079] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a crushing mechanism 6, which includes a crushing barrel 61, a feed port 62, a blade 63 and a third handle 64, the upper part of the leg 1 is provided with a crushing barrel 61, and the distillation frame 41 and the stirring The crushing barrel 61 is connected, and the left and right sides of the top of the crushing barrel 61 are provided with feeding ports 62, and a blade 63 is rotatably connected between the inside of the left side and the right side of the crushing barrel 61, and a third handle is provided on the left side of the blade 63 64.

[0080] People pour sewage into the feed port 62, and the sewage flows into the crushing bucket 61 due to gravity, and then flows into the distillation frame 41. At the same time, people manually turn the third handle 64, and the rotation of the third handle 64 makes the blade 63 rotate. 63 crush the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com