A Metal-Organic Decomposition Growth Method of Metastable Phase Rare Earth Nickel Oxide Thin Films

A metal-organic decomposition and oxide thin film technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problem of relying on vacuum process, difficult to achieve large thickness and high uniform deposition growth, difficult to achieve large area deposition, etc. problems, to achieve the effect of large deposition thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

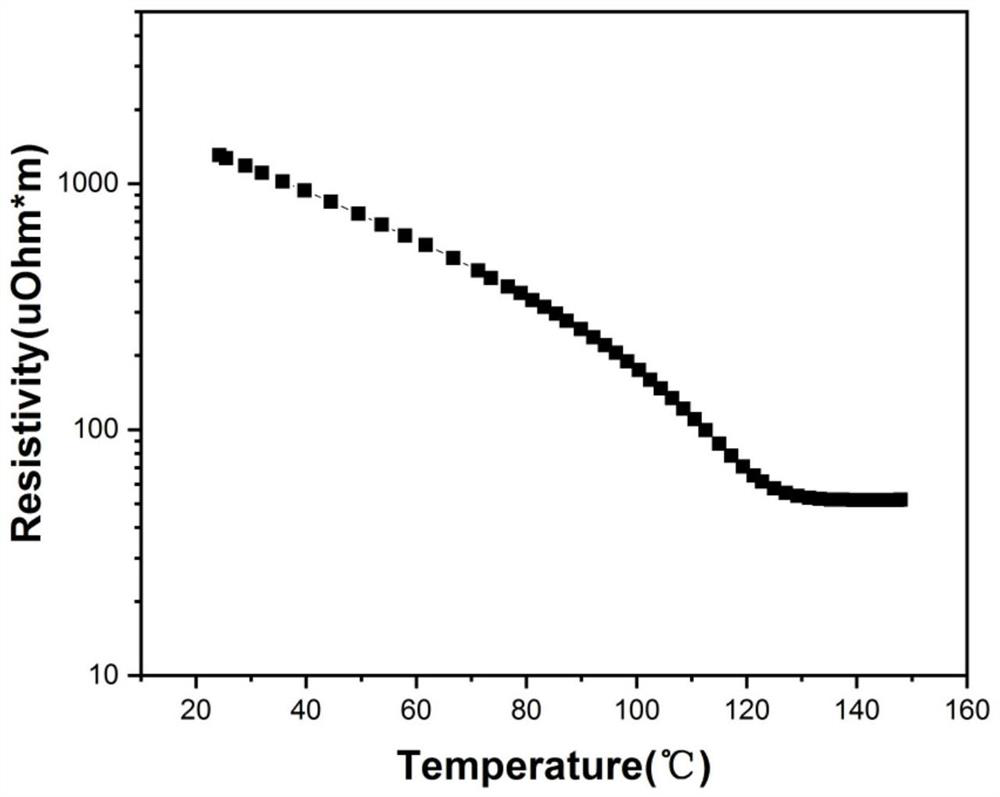

[0024] Embodiment 1: using isooctanoic acid, samarium acetate hydrate, nickel acetate hydrate, ammonia water, xylene, etc. as initial raw materials; a certain proportion of samarium acetate, isooctanoic acid, and ammonia water are mixed, fully reacted and dried under stirring, Obtain samarium isooctanoate; mix a certain proportion of nickel acetate, isooctanoic acid and ammonia water, react fully under stirring and dry to obtain nickel isooctanoate. Mix the prepared samarium isooctanoate and nickel isooctanoate at a molar ratio of 1:1, and dissolve them in xylene solution; use the ratio of samarium isooctanoate, nickel isooctanoate and xylene solvent to control the thickness and uniformity of the film. Further, 100 drops of the above solution were spin-coated on the lanthanum aluminate substrate and dried; then annealed at 600 degrees Celsius and 500 MPa oxygen for 48 hours to obtain a samarium-nickel-oxygen thin film material. In one optimized condition experiment, the solute...

Embodiment 2

[0025] Example 2: Prepare samarium isobutyrate and nickel isobutyrate in advance, mix them at a molar ratio of 1:1, and dissolve them in xylene solution, and control the concentration and viscosity of the prepared solution to an optimal range. The above solution was spin-coated on a lanthanum aluminate substrate and dried; then annealed at 1200 degrees Celsius and 900 MPa oxygen for 0.5 hours to obtain a samarium-nickel-oxygen thin film material. The prepared film has obvious metal-insulator phase transition characteristics near 120 degrees Celsius, and its insulator phase has typical negative temperature resistance coefficient thermistor electrical transport characteristics in a wide temperature range below the phase transition temperature. Compared with the case of using the same solvent and having the same concentration of nickel isooctanoate and samarium isooctanoate as the solute in Example 1, the viscosity of the precursor solution is lower, and the film obtained subseque...

Embodiment 3

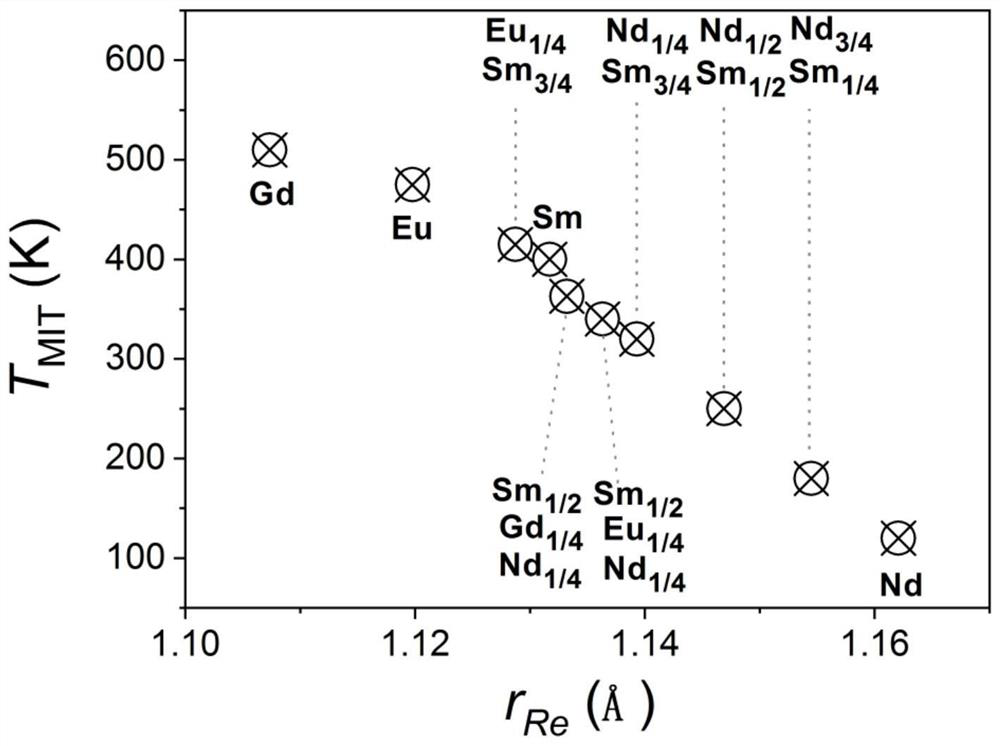

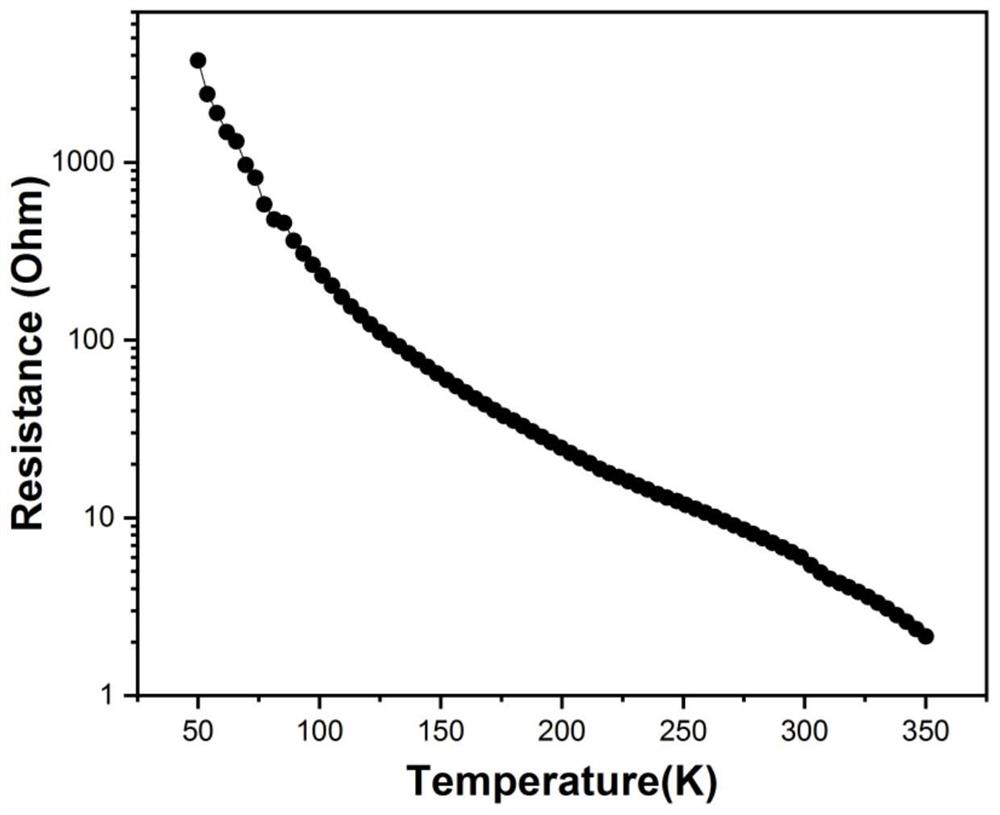

[0026] Example 3: Prepare neodymium isooctanoate and nickel isooctanoate in advance, mix them at a molar ratio of 1:1, and dissolve them in xylene solution, and control the concentration and viscosity of the prepared solution to an optimal range. The above solution was spin-coated on a silicon substrate and dried; then annealed at 900 degrees Celsius and 0.2 MPa oxygen for 50 hours to obtain a neodymium-nickel-oxygen thin film material. The prepared film has obvious metal-insulator phase transition characteristics around 120 Kelvin, such as figure 2 Shown; In a wide temperature range below the phase transition temperature, its insulator phase has typical electrical transport characteristics of a negative temperature coefficient thermistor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com